How important is to have a draw bench to make all kinds of wires your self , sould i buy one or should i make one ? is it actually worth making a drawbench or is better to buy one from a reputable company .

You only need a drawbench if you are going to be drawing very thick wire or tubing. For the majority of jewelry work you will be drawing short lengths of rather thin wire and narrow tubing. A drawplate held in a vise bolted to a sturdy workbench is sufficient for the vast majority of wire and tubing you will need.

i agreed with you but do you know when you going to need it for thick wire ? , if you just make little earings or fix rings is ok but if you are making chains and doing fabrication only like i do , anything over 2mm you cant pull by hands

In that case, it is certainly less expensive to make one than to buy one. You can also make one that is significantly longer than the commercially available ones, assuming there’s room in your studio.

abielr68140 my friend … looks like you got some deep pockets … lol. That thing is a monster. If I put it in my workshop … I’d have no where to sit. Better idea perhaps … buy a Durston Combo mill with wire rollers. Here is what I do when I want say 10ga wire or really any wire. I pour an ingot or two, swage them a bit with a heavy hammer … turning them to keep them roundish. Asking about hammering an ingot before rolling will create a mess of different opinions  I hammer because I just like to beat things with a hammer. The rolling mill can handle just about any wire ingot you can pour. You’ll end up with a squarish wire you can aneal and start drawing through a plate. If you chose to buy a mill, buy a good one - which is basically a Durston if you are in the US. I have the 130mm combo and love it. Make sure you get the one with reduction gears … unless you have arms like Popeye. Half round side rollers are nice to. Don’t bother with the smaller, less expensive mills … they can’t handle something like an ingot. Don’t buy a used mill … made that mistake years ago when I was trying to save money. Bought one of those “India” mills too … pretty good little mill, but again can’t handle much. You’d just have to sit one side by side with a Durston to understand the difference … its like comparing a VW to a Mack truck. I know Durston has entered the market with some lower priced mills to compete with the Pepe ones and such … if you can afford it … buy a bigger one. I’m presently lusting after the one with the wheel handle … think they call it the Olivia … but no way I can justify buying one just because I want it. The 130 combo does everything I could possibly need to do. Just my two cents. Or my nickle because I’m chatty

I hammer because I just like to beat things with a hammer. The rolling mill can handle just about any wire ingot you can pour. You’ll end up with a squarish wire you can aneal and start drawing through a plate. If you chose to buy a mill, buy a good one - which is basically a Durston if you are in the US. I have the 130mm combo and love it. Make sure you get the one with reduction gears … unless you have arms like Popeye. Half round side rollers are nice to. Don’t bother with the smaller, less expensive mills … they can’t handle something like an ingot. Don’t buy a used mill … made that mistake years ago when I was trying to save money. Bought one of those “India” mills too … pretty good little mill, but again can’t handle much. You’d just have to sit one side by side with a Durston to understand the difference … its like comparing a VW to a Mack truck. I know Durston has entered the market with some lower priced mills to compete with the Pepe ones and such … if you can afford it … buy a bigger one. I’m presently lusting after the one with the wheel handle … think they call it the Olivia … but no way I can justify buying one just because I want it. The 130 combo does everything I could possibly need to do. Just my two cents. Or my nickle because I’m chatty

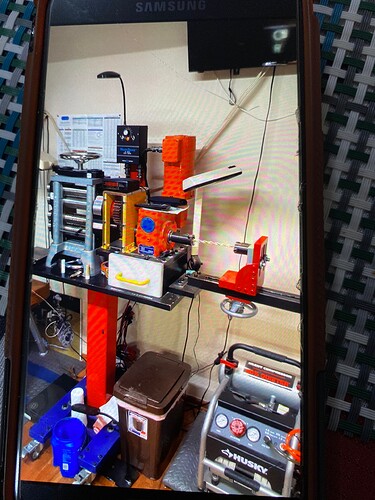

Well i would say that if you want to buy for example a durston drawbench the price of the drawbench is not that expensive and durston make some decent drawbenches , now if you are a tool junkie like me and want to build one like the picts i post ,that is a drawbench i build years ago when i had my machine shop , its not worth doing it it cost a lot more than buying one , also you can make a simple one with a boat winch fron harbor freigh and two L brakets at the end to hold the draw plates and make it as long as you want thats the economic way to do it and will do the job up to a certain level , now if you have to draw a 5 mm wire to make a thick chain your arms are going to suffer puling a 5 mm wire by hand with a harbor freight boat winch . i had pull 10mm wire with the one i build like if the wire was made out of butter .

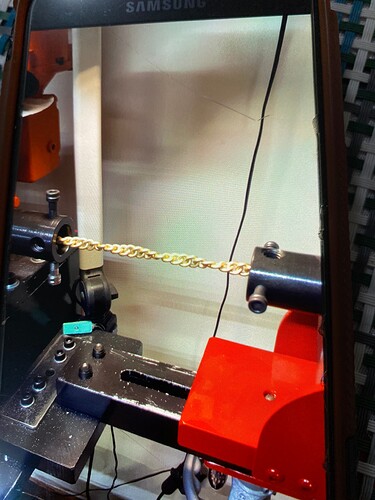

the drawbench you see in the pict is actually not that big the pict make it look s lot bigger that what it is i think is about 54" long only and yea i love the durston rolling mills i have one duplex durston rolling mill that i modified to also twist some heavy miami cuban lynk chains and also i motorised too i have arthritis and rolling by hand is difficult for me . here are some picts

I made one of those boat winch drawbench one time. Never used it and gave it away. Like beating things with a hammer … I kinda like jerking wire through a drawplate  Tubing … ain’t ever going to do that again … boy that was a pain. Commercial tubing is cheap and if you need something bigger … at some point just fabricating a round from sheet is easier … assuming you are using the tubing to make bezels or something like that. I’d love to see your shop

Tubing … ain’t ever going to do that again … boy that was a pain. Commercial tubing is cheap and if you need something bigger … at some point just fabricating a round from sheet is easier … assuming you are using the tubing to make bezels or something like that. I’d love to see your shop

all i do is fabrication so i use the draw bench all the time i dont like to buy parts allready made i like to fabricate every part by hand if you have a bussines and you need to produce ,is better to buy parts allready made but since what i do is a hobby for me is a learning experience to make every part and if you dont have the right tools you cant make them

And if you made that drawbench … I’m very impressed!

yea that that was years ago when i just to have a small machine shop i dont have the machining tools any more but i still have the drawbench

I made a boat winch, 2X6 board, plate stop draw bench that I use all the time. I added a small pulley that allows me to make a continuous draw longer than the bench. The tongs were the most expensive part of the project. Other than plates, I don’t think that I have more than $120 in it. I am often drawing 8 gauge wire down to smaller sizes. I also use it to draw round wire into square and triangular shapes. It is especially good at straightening stock that has lost its shape in being rolled. Smaller diameter wire can be first drawn on the bench and then, as Elliot suggested, mount the plate in a vise and draw the wire across your shop. I do this when making filigree wire. Take a look at the shop shots page on my website www.robmeixner.com to see pictures. They don’t show the pulley that I use to do draws longer than the bench. It is a simple wooden pulley set between the plate and the winch that I can wrap wire around until it is short enough to continue drawing. It is only limited to how much wire I can wrap around the pulley before the coil starts to slide off. I have little reason to buy a Durston or any other bench regardless of how well they are made. I have considered making a motorized bench with a 10 - 12 inch diameter metal drum driven by a gear motor that pulls the wire through the draw plate and then winds it on the drum. Lots of fun…Rob

yea its always fun to make your own tools also

If you need round wire, square wire or D shaped wire, you can make various gauges of these with the right rollers on a rolling mill, right? So whether you need a draw bench or not might depend on your need for wire shapes and gauges which you could not make with your rolling mill. I wonder if you could make triangular wire with one square wire roller and one flat roller or by putting two round wires into a square wire groove…I guess it might come down to a question of economics, too. How often would you need some particular shape of heavy wire and would it be easier to order it than to spend the money on a largely-idle draw bench to draw it? Interested in various folks’ answers to this question…

royjohn…You are correct that you can make various shapes using your rolling mill. Square (kind of), is easy, just use the square grooves and reduce until you get to the size you want. I do this often, but I also need clean edge square wire and the only way to get it is with a draw plate. You can double over two pieces of round wire and run them through the square grooves on a rolling mill and get two pieces of triangular wire. This is really tricky and very hard to keep lined up. If you need clean edges, use a draw plate. I also modified a flat roller on my economy mill to roll various sizes of triangular wire. In the end, I decided that trying to use the rolling mill to make triangular wire was a waste of time and I draw it or buy it. Square wire is a different story. Sometimes the square from the mill is fine, other times I need it to be clean edged, so I draw it or buy it. This is all a vast improvement over the years when I used to forge triangular, half round and square wire out of 4 - 8 gauge wire using grooves machined into a steel block…Rob

Hi ,

I made my draw bench with a Dutton Lainson pulling winch and i love it.

it is 2 speed (direct drive, and 5.4:1 gear ratio)

the main reason i selected this winch is that it has a detachable/ quick change handle (used to switch from direct drive to the geared axle) that i can remove for convenience sake.

at the time, winches were in short supply…due to steel supply issues which were affecting alot of tool vendors i spoke to…i hunted down my particular winch on Ebay…$65 new…(the current price on the D-L website is $99…which is about a 52% increase…![]()

![]()

julie

i agreed with you you can make a few tricks with the rolling mill but in order to get a perfect wire of any shape you have to use the drawplates again for someone doing only fabrication jewelry , not buying any allready made parts a drawbench is very useful to fabricate your own wire round square or any other shape if you have a drawbench and is been idle in a corner means that you do not fabricate chains bracelets or any parts that use wires of any kind and i think is a big part of jewelry fabrication . now if you just make a few rings and a few earings and you do not want to spand your fabrication skills into making other pieces its fine not to own a drawbench

nice thats cool i have simple winch with an attachement that i machine out of a solid block of aluminum to fit all my drawplates the bigones and the smallones ,picts below also a home made draw thong.

Hi,

those are gorgeous draw tongs!

your drawplate holder looks like a very desirable item!

an orchid member showed a great pair of vise grip pliers with his draw bench…i got a pair for mine…unfortunately, am not a handy machinist!…it has a great eye bolt tightening nut!

that should work as well