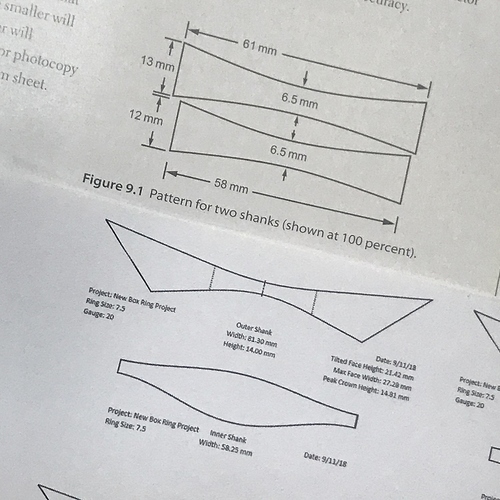

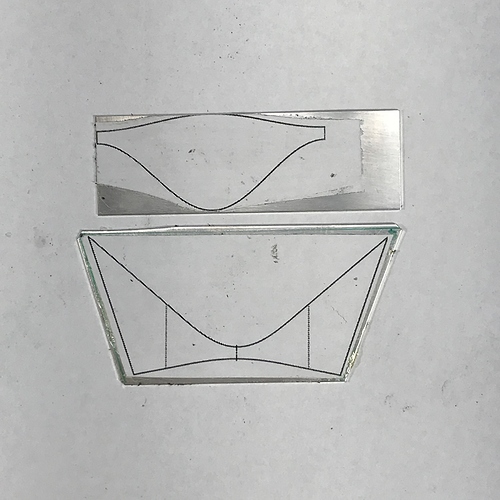

Just over a year ago, I began a topic discussing box rings (Box Rings and Modifications). I was truly fascinated by this form. I still am. From an intuitive perspective and with just a little math thrown in, I presented a template that enhanced the one found in Alan Revere’s book, Professional Jewelry Making. From there, I offered a number of modifications that could be applied to that template to achieve various results, including moving the solder joint on the shank, and shifting the basic curves to make asymmetric rings.

The problem with my approach at that time was that it took a lot of work (relatively speaking) to create the right size or proportion for some ring features. This is particularly important when you want to, for example, add an embellishment like a particular stone. I’ve made my share of rings with faces too small to accommodate my original needs. It’s frustrating to say the least.

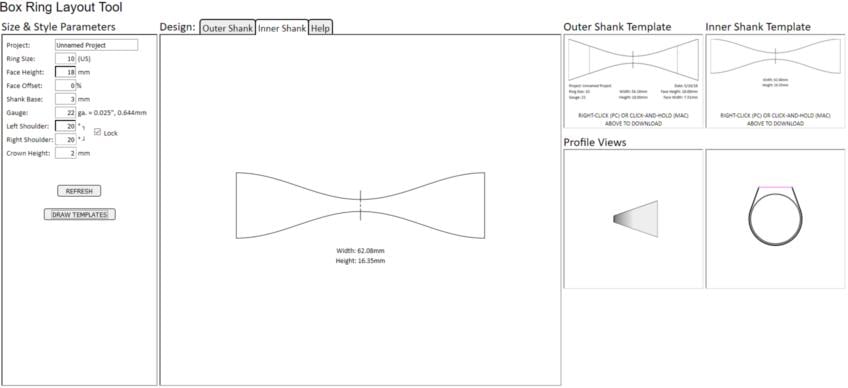

So this all brings me to the present. My box ring “obsession” led me to develop a layout tool that handles all the fun trigonometric calculations (and there are a lot of them) and template drawing automatically.

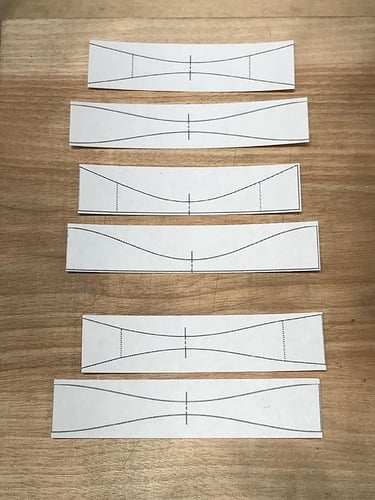

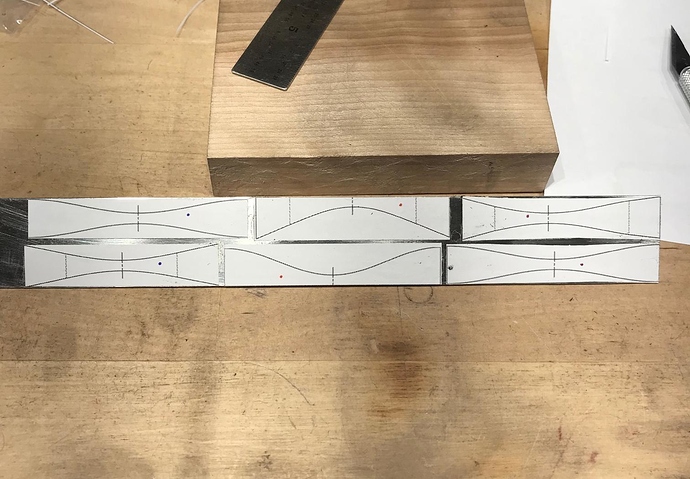

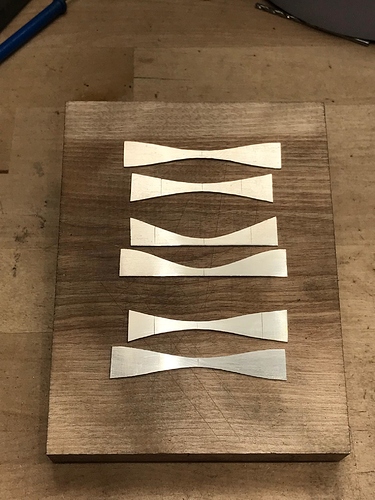

To use it, all you have to do is enter your design parameters, save and scale a couple of images, and print them out to transfer to your stock.

Before someone says I could just have used a CAD program, yeah, I could have, but where’s the fun in that? Seriously, I undertook this project to gain a full understanding of this form. I’m still working toward that, by the way. The original program was very simple. It kept growing. It keeps growing. There’s more coming. (I have a list: international ring size standards, more face modifications, a top-down profile view, etc.)

In the meantime, if you want to play with it yourself: tools.easilydistractedbyshinyobjects.com

It’s password protected (primarily to keep out badly behaved robots), but just enter “orchid” and “ganoksin” for the username and password.

There’s not full documentation yet. There will be. There are bugs. There always are. Some things I just haven’t gotten to. Some things I’ve missed. I’ll get to them. Both. This is not intended for use on small mobile devices. I’ve only tested it myself on a PC running Windows. Your results may vary.

-Alec