Among my favorite books is Alan Revere’s “Professional Jewelry Making.” It’s really helped me improve my technique, as well as given me a better understanding about metal working and how materials respond to force, heat, etc. I’m particularly fond of the “Box Ring” chapter, and have explored this form in several ways. I just finished a very different practice piece, and wanted to share some of what I’ve learned along the way.

For brevity, I’ll skip the basics of a box ring, and assume you either know this form, or will look it up in Mr. Revere’s book.

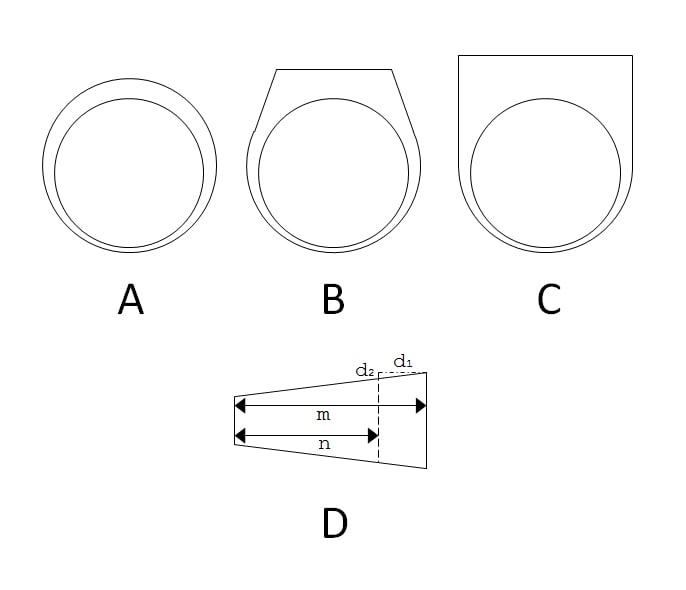

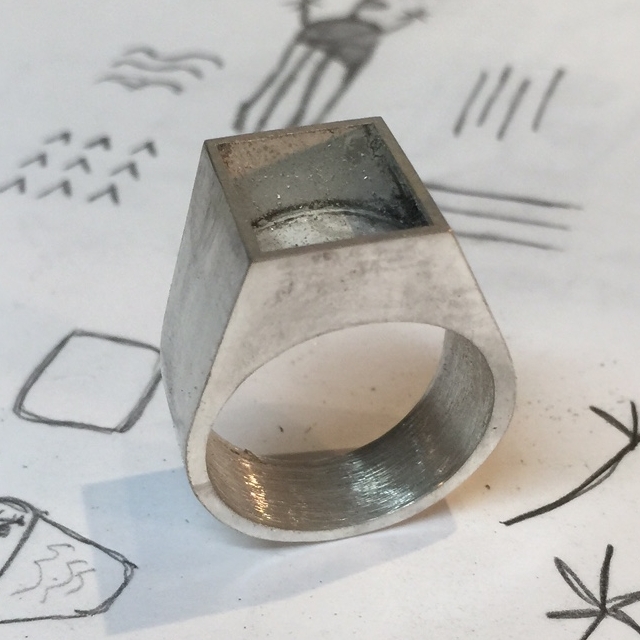

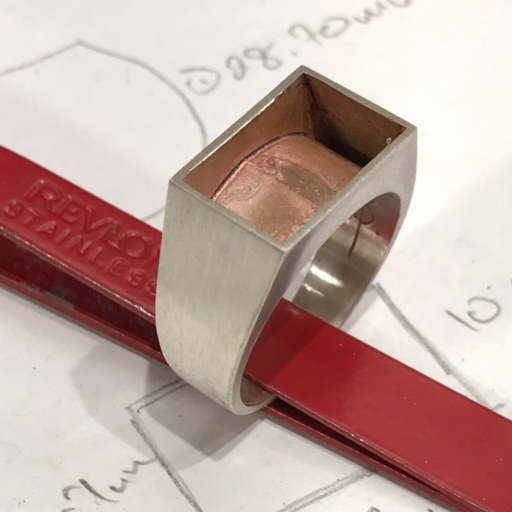

My First Box Ring Attempt

The above is my first try at a box ring, before the face was applied. I went step-by-step, using the Box Ring chapter’s instructions, and everything went pretty smoothly. However, I think there’s a small issue with the shank template as presented in the book.

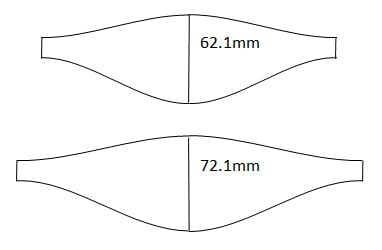

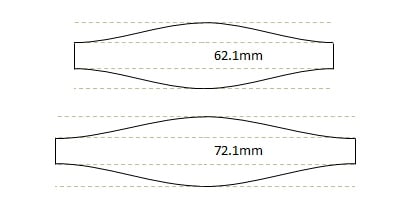

Original Shank Template

When the two wide ends of the inside shank are joined and trued to a circle, those ends come to an oblique point, and the sides of ring don’t define a plane. That point has to be filed off the shank before the sides can be attached. Wider ring faces will have even more dramatic points.

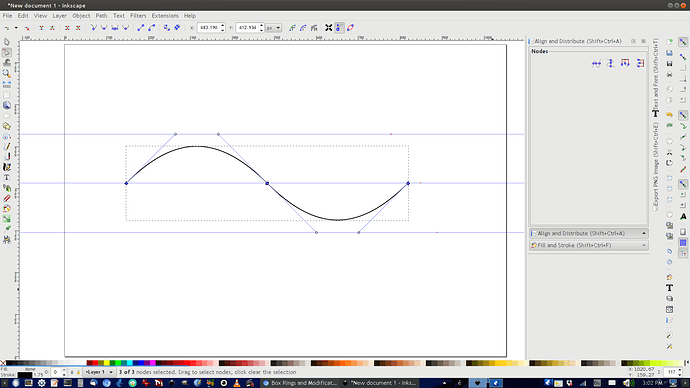

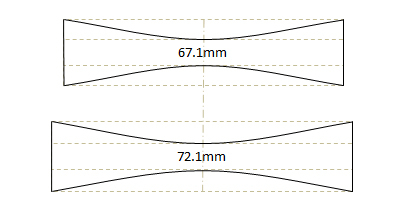

Modified Shank Template

This is my modified template. The shapes along either edge are sine curves (note how the slope of the curve decreases toward the ends and center), and what happens when these are formed into circles is the edges come together with perfection (assuming you’ve cut the shank without error). That means when filing the sides flat, a lot less material needs to be removed.

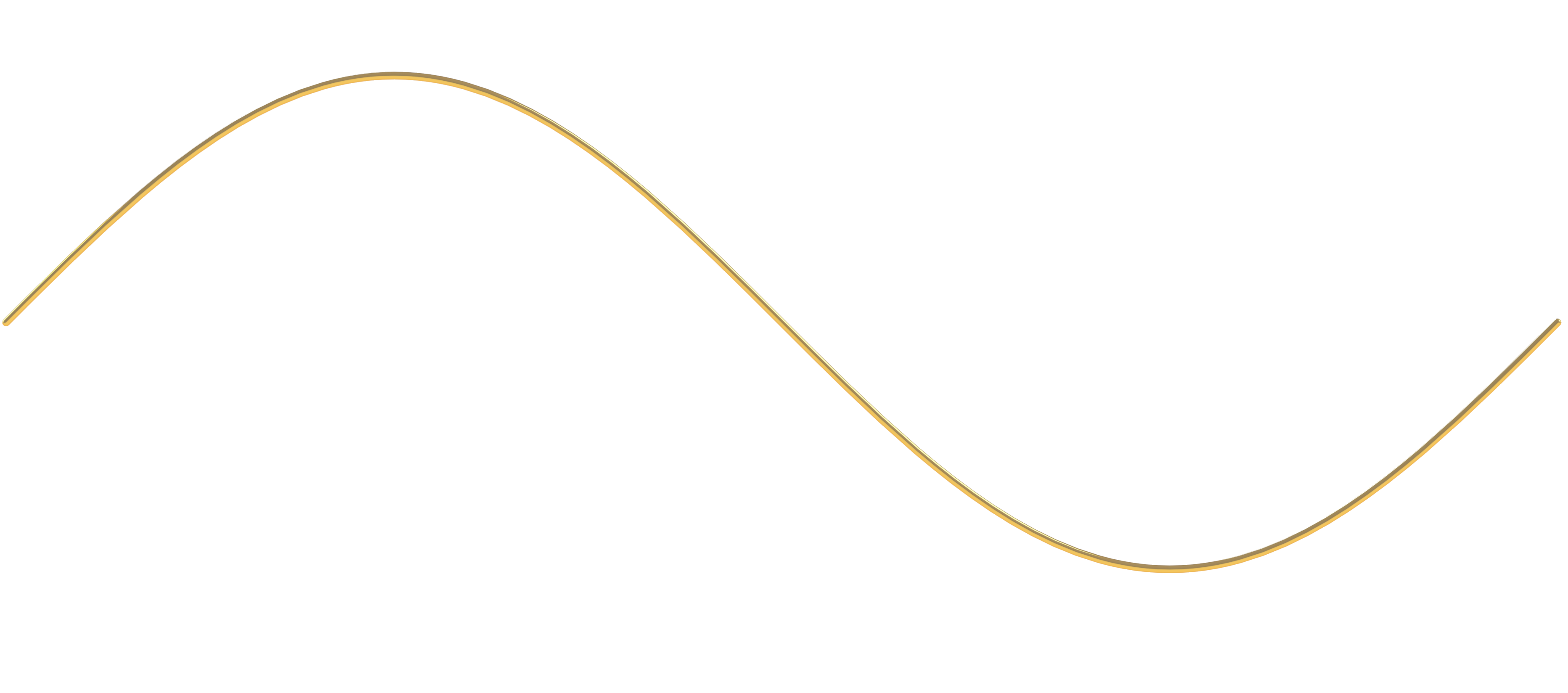

A Narrower Box Face

The sine curves are beautiful things, because their length and width can be changed independently of each other to make different sized shanks or faces, and as long the sine shape is maintained, they’ll always come together to form a perfectly flat side. (Not to be too persnickety, but yes, because the outer shank’s ends are left free, this sine curve rule breaks where the shank diverges from the circle.)

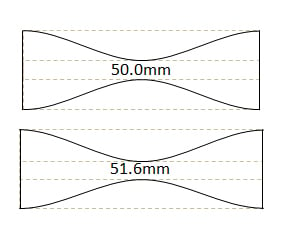

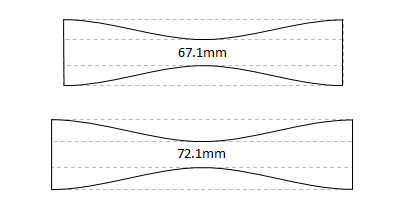

Reversed Shank Template

My practice piece, the one I mentioned at the beginning of this post, is a little different. I split the shank templates in the middle, and flipped them end-wise to set the joint of the shank at its narrowest point. I also made the outer shank much larger relative to the inner shank. Instead of adding a flat face, I wanted to raise the face of the ring on a stake, creating a domed surface.

My Completed Practice Piece

I know this is basic for a lot of folks here, but I hope that it gives others who are novices like me some insight and help on shape and form.

Thanks for reading.

Alec