_**“What's the name of that bur?”**_

When are they used, why & how?

(I am not here to publish which tool-supplier, brand name of burs is superior over the next. The decision will be left up to you. As in every country, there are different companies who will serve you the best!)

1) 156C, 2) Round, 3) Bud-shape, 4) H.S.S. aka (High Speed Steel),

5) “77B” aka (Cup Burs).

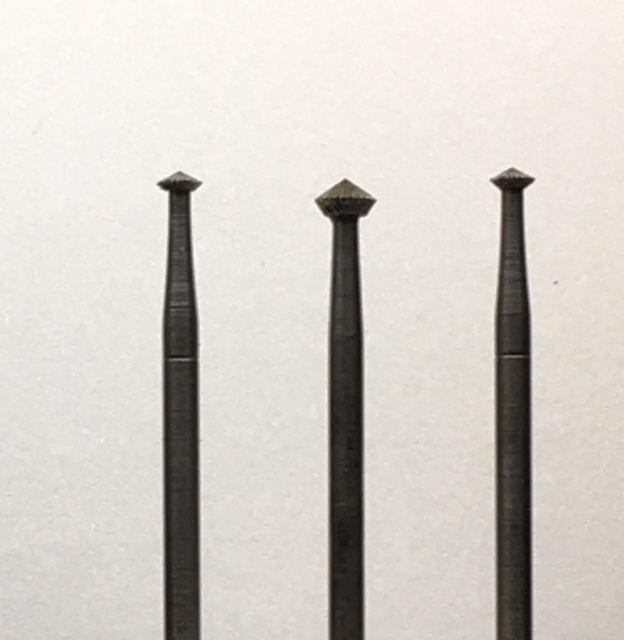

This one bur, (156C-Carbide) has four names:

- “Under-Cutting” bur.

- “Bearing Cutter”.

- The generic name of “414”, or “156C” (C meaning Carbide).

- “Hart shaped bur”.

You can use these various burs in the following places!

The 7, ‘demo-topics’ in this technical essay are;

Channel Setting.

Gypsy/Flush Setting.

Mini-cluster ring.

Pin-Setting.

4-Claw setting

6-Claw setting.

Princess, Square-Cut stone

Along with each bur-name comes some of the reasons for being used. I will demonstrate how these burs can literally have multiple names, depending on their immediate uses! These are really very busy burs!!

I will now explain the many uses, with the aid of photography.

For “Under-Cutting” the process of ‘making a seat’ for the stone is important. There is no other bur that can accurately provide this service, why?

It helps you to carve out a little recess into the claw/prong and allows the stone to sit in & against the metal

.

My angle preference for all of these burs must be at @ 90-degrees.

These burs come in 70-degree angles, but there isn’t any stone of that shallow angle, is there?

The next bur is the “High Speed Steel” cutting bur. As this is a very special item, I use this special cutting bur for only “Engagement; 4 & 6-claw as this bur is a very ‘aggressive’ cutting bur. The 156-Carbide bur cannot supply this action why?

Each High Speed Steel (a.k.a.) HSS bur is hand-cut on a lathe, the teeth are deeper into the metal & the teeth are further apart.

But this bur serves a dual purpose! It cuts much deeper into the claws, I know just how much metal will be removed and how the bearings will be made. As this bur is hand-made, there is one downside, the girdle cuts are not as ‘true’ as in the carbide edge, or cutting into the bearings. But I overcome that, by using a small #007 round bur to make a clean ‘bearing-cut’ where the girdle of the stone will be located. The HSS bur cuts both the Pavilion & Crown-Facets, together.

The third use of the 156C bur is named a ‘bearing-cutter’ it literally cuts grooves into the small claws. Its name is quite obvious, its purpose is to cut ‘seats’ for the girdle, for very small stones.

A ring in a ‘Cluster-top’ pattern, I will not use a HSS bur, but I would use a “156C” in its place. As both are made of Carbon Steel, but the HSS has been created differently and is very long lasting in the constant use in the ‘family of burs’, but working under different situations.

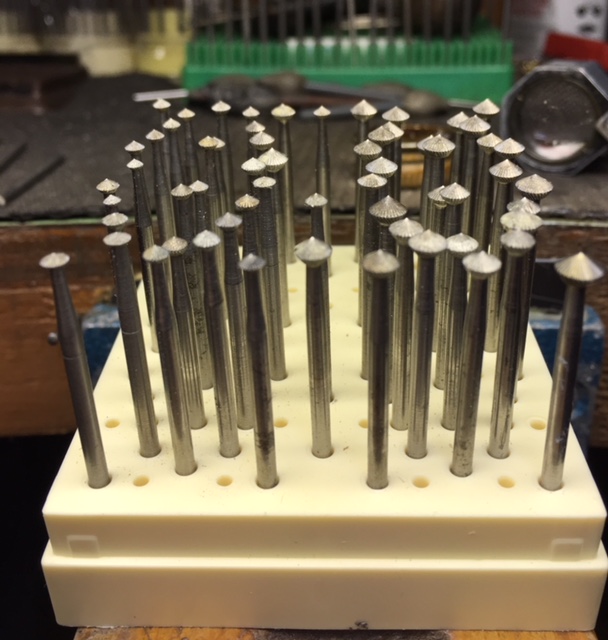

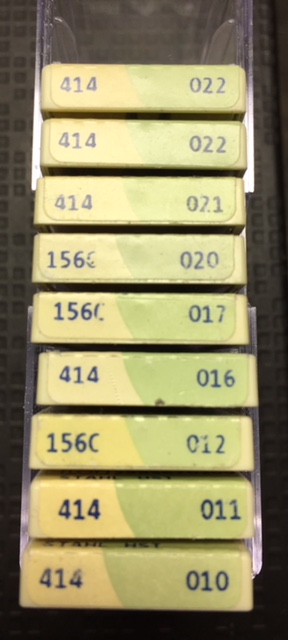

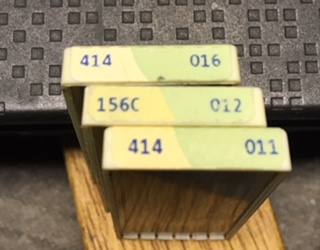

The generic name bur “156C” or “414”, is shown in this ‘6-bur-package’, these burs are the ‘best friends’ of setters.

I invent situations where one bur can be made interchangeable with another & still produce quality workmanship.

(But then again, I wouldn’t use the aggressive “High Speed Steel” in any of these Cluster-top instances.)

When I need an exact or a fine cutting of delicate burs, I will use the 156C and no other! When I require to have more metal to be removed, I will of course use the HSS bur. Each bur-shape will have its own specific limitations, and I will attempt to show them, in this essay.

Some burs are really fantastic, it’s for you to decide which, where & when! In this essay, I am here giving you a “Bur-guide”, the actual stone-setting is up to you. Enjoy the photographs, have fun setting your stones.

Let me start off with the multitude uses of a simple ‘round bur’, this list is long! Sit back and enjoy the reading.

Gypsy-Flush Settings: Here you should use a round bur, why? To make sure the opening for the stone is perfectly round underneath.

How large a bur? At a stone of 3.00 mm’s the bur size will be #018. This is just to make the access opening round and have a chance for the dirt to escape. Here again ‘another round’ bur, but at approximately 80% of the size of the stone. This bur will clean out any pieces of metal where the stones “Pavilion” will be sitting in & against Bur size of #026.

There could be some casting defects or little unseen pieces of metal in not allowing the stone to sit properly, as this does sometimes happen! This is just to make the opening round & clean!

I will use the “Round-shape” bur to ‘counter-sink’ the underside of each and every hole. This purpose is to clean & make sure each hole is uniform in size and depth.

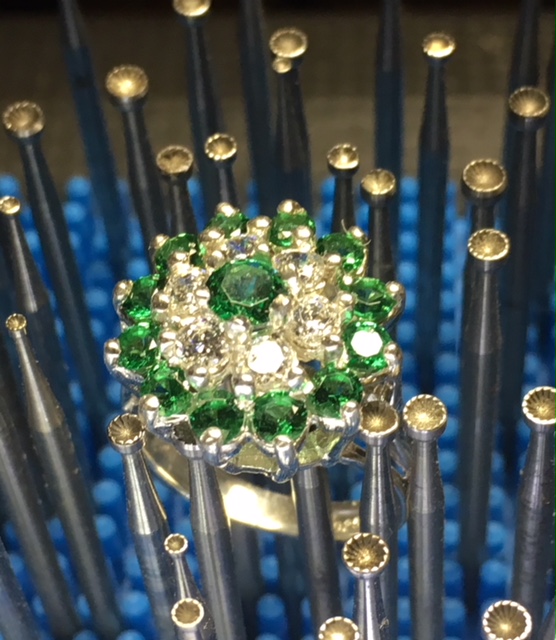

Cluster Rings: This is a ‘generic’ assembly of rings for this ‘all-in-one’ demonstration. Many cluster-rings will have the same degree of cleaning needs. This ‘demo-ring’ is easier & larger for you to see.

If the opening is for a stone is at 3.00mm’s, then the required round bur size must not exceed 2.50mm’s. This bur designation is #025! The round bur will clean as it prepares for the stone to sit in the ‘cleaned & round’ setting hole!

Channel Setting: If the stone size is 2.75mm’s, then the Round bur should not be larger than 2.25mm’s.The bur designation #021.

Here we are attempting to clean all of the holes and to prepare for the setting. This bur will leave a clean inner surface for the stone to sit against but they won’t be sitting in the ring, but slightly raised!

The next bur for this ring will be the “156C Hart-Shaped” bur, why this name for the same bur? You could call it an “Under-Cutting” bur or any other name, just long as it works, correct? For a stone of 2.75mm’s. I will use a bur designation of #022.

This bur is only used for cutting bearings inside of the Channel.

“Pin-Setting” This style is the same, but the name has changed. This style as shown here has been created many times in the CAD process, namely “Computer Aided Design” program. It allows only the smallest stones to be set, then we can use even the smallest burs as well. Depending what the size of stone we will use, still the bottom of the multiple claws need to be ‘cleaned out’.

In this close proximity to each claw, please avoid using the rough cutting HSS, use only the fine, bur-cutting 156C bur. Please be thoughtful of the bottom of the setting and use a bur to prepare to clean out where the Culet will be. I suggest a round bur of #008. The size of the bur that will do the bearing is your decision.

Remembering the 156C small bur, I suggest maybe a #012! Another option would be is to buy a “6-pack” of numerous sizes of burs, ‘not of your beers’, but of burs. Always good to have extra’s on hand, I suggest both ‘Beers & Burs’. “If you mess-up, hava drink!”

“4, or 6-Claw Setting! Engagement Rings”

The main selection of burs needed here are as follows; Bud bur of #008, this for the HSS (bur stopping), another round bur with same diameter that of the width of the Girdle of the stone. <= (this is “your size” decision)

When searching for the size of your High Speed Bur, always think of a bur at 75% of the diameter of the stone you need to set.

For example; a 6.00 mm stone, you ‘could’ buy a 4.50mm bur!

This ruling applies to the preparation of a 6-claw Engagement ring, but with one difference! When you have to prepare the multi-claw setting, sometimes the claws just won’t give you much room to ‘get in there’. You might have to use a #007 round bur to make a little preparation for the HSS bur further on. Remembering the equation of; “75% of the size of the stone, is your size of the bur”.

Princess, Square-cut stones!

This grouping of burs is very detailed, I feel that the bur selection is very important in setting of this very delicate & very expensive stone.

Here is your bur listing!

Round-Bur number #008, is used for the corner of the “VEE” claws. Bud shape bur #008 will cut the intersecting Pavilion facets from the round #008, to the bottom of that claw. The size of the bur at #009, will cut the metal at a 45-degree angle inside of the Gallery. This angle will allow the Pavilion to sit against the ring.

For the ‘bearing-cuts’ the bur size is depending on the width of the Girdle of your stone.

This is such an important setting process, all of this setting depends upon the correct sizes of these 5 burs, and where!!

“Cup-Bur” aka, 77B! The size of the bur depends upon the diameter of the claw. The chosen size should be one size larger, than the claw itself.

I think that this is important now to include a “Cup-Bur” or aptly known as a “77b”. It makes every claw rounded in its appearance and shape.

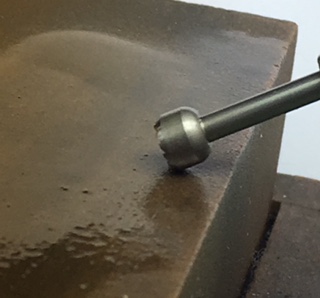

Instead of filing to trim, all you do is to place the bur on your claw at 15-degree incline away from the stone, and rotate the bur in a ‘clock-wise’ circular motion. I will taper off the bur edges on an oil stone, just to make the teeth to have more contact with the stone, but not interfering with the facets, to eventually chip them, this is not nice!!!) This is fully explained in the photographs.

On Cluster-Ring settings, this ‘Cup-Bur’ can be used to clean and round- off the claws. As well on the CAD created mini-claws!

Now you have the most important guide in buying your burs:

No more guessing, no more buying the wrong sizes, no more attempting to substitute one size for the other.

BTW, the bur size designation is #025 means 2.5 mm’s. #030 means 3 mm’s.

Now you can now walk into your favourite in town tool-supplier or go online to write and let them know what you need in the correct size and shape.

Remember again, "PLEASE DO NOT PURCHASE ANY 70-DEGREE ANGLE BUR!"

Regards, as always…Gerry Lewy! “gerrylewy18@gmail.com”