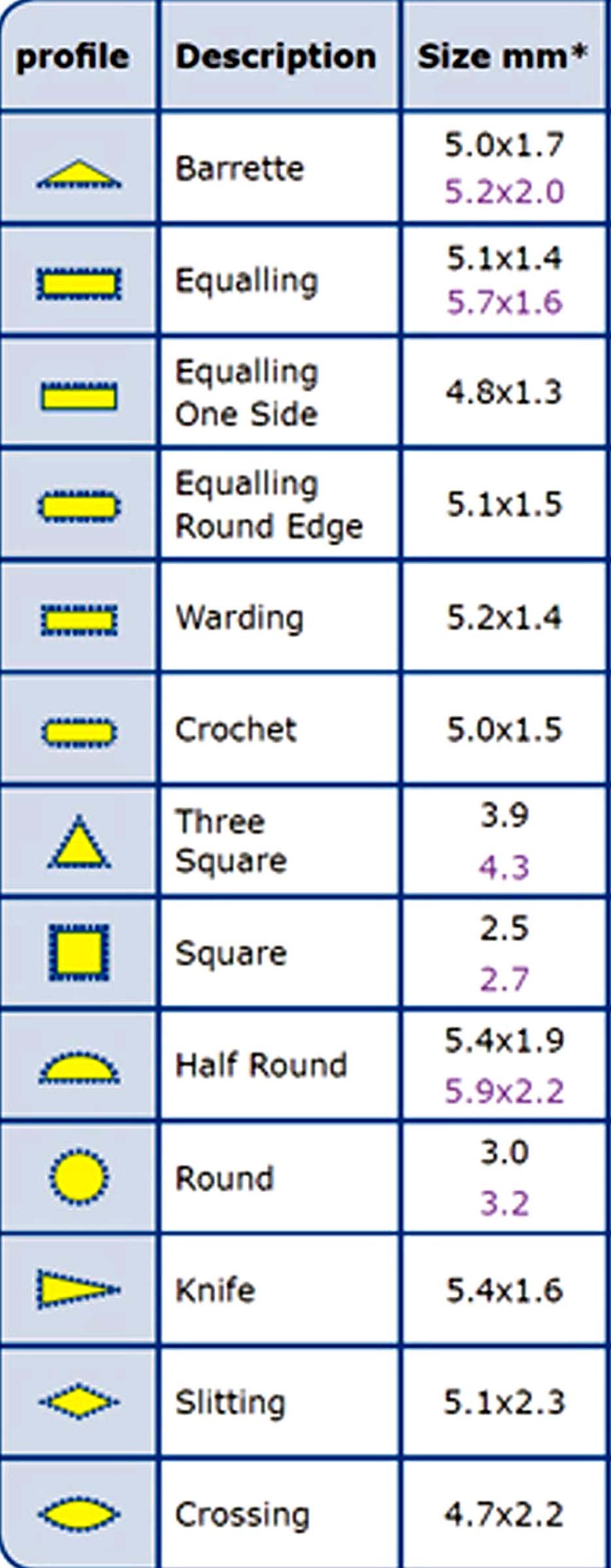

This chart show needle file profiles.

I forgot to mention that I now like using KnewConcept saw frames.

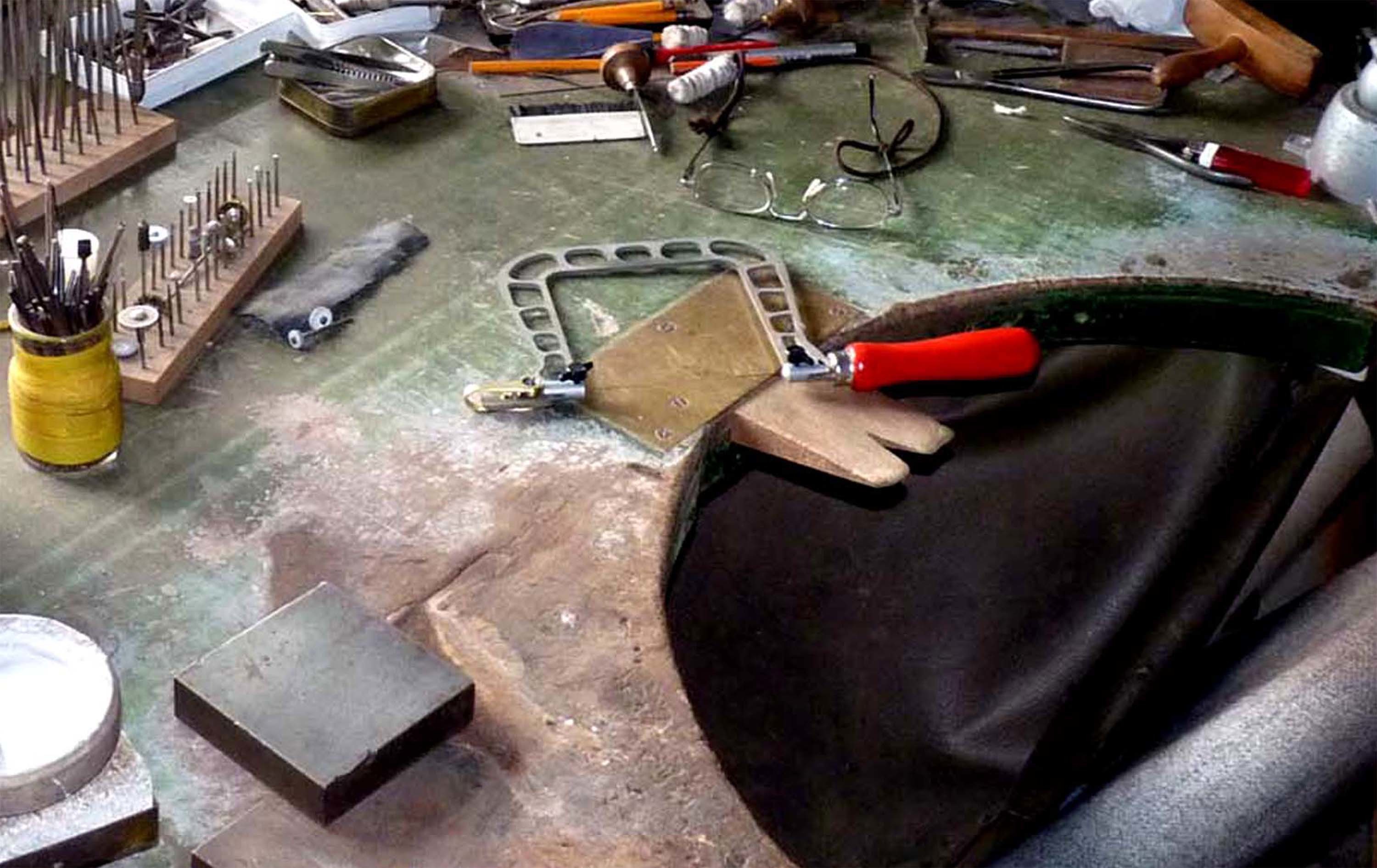

I forgot to mention that I use candle wax as a saw blade lubricant when piercing, and to avoid filling the blade teeth with rubbish I rub the candle wax on the rear of the saw blade which lubricates the blade sides without filling the blade teeth with wax. You can see my candles behind my spectacles on my bench, also my now favourite saw frame, a Knew concept Ti frame with the lever tension.

Love seeing your bench!

So I took some pictures as I am sure I am not explaining myself very well …

Here are one of my needle file sets (they are found everywhere and I think they are super common) and in comparison are the tinyyy files I got from the jeweler’s shed that I am wondering if they are actually escapement files. Or are escapement files even SMALLER than these tiny things??

Front view …

Top view …

Comparing the flats …

Comparing the rounds …

How they were packed when I found them …

These files below I also have NO idea what types they might be and there are more of them. No markings on the file themselves and all the handles say is “Made in England”. Most of them are SUPPPPPPPERRRRRR smooth. No idea what tooth or grit they are.

What is the term for files in determining coarseness anyways? it is tooth, grit, cut, or something else?

I took a video of them as well in case the pictures weren’t clear enough - my phone camera was being a problem child and not focusing for the stills or for parts of the video, lol.

[quote=“jamesmiller046, post:23, topic:54730, full:true”]

I forgot to mention that I use candle wax as a saw blade lubricant when piercing, and to avoid filling the blade teeth with rubbish I rub the candle wax on the rear of the saw blade which lubricates the blade sides without filling the blade teeth with wax. [/quote]

I heard someone else mention that somewhere - they said to lube the back of the blade - so I started doing that but I kept doing the teeth as well, I didn’t understand why the back would help but she is one of those that you know knows what she is doing (she’s not the type to answer questions very well though sadly so I didn’t ask her to clarify).

I thought we lubed the teeth to help them cut into the metal and stay sharp, but you are saying that it is for the SIDES of the blade??? Really??? I would have never guessed! So filling the teeth with lube would actually make it work LESS effectively then, yes?

So just a regular candle - not a bees wax? And not a commercially made lubricant? Might I ask why … what is the rationalization?

I tried to use the 3 inch deep Knew Concept saw that I just got - its not as deep as yours - but I keep breaking blades or they pop out when I try to tighten them. I have the old kind with the screws, not the levers. I got so mad that I went back to my simple german frame saw. there must be some trick to inserting a blade and having the right tension - but then like Julie was saying … maybe I am over-tightening across the board too adding to my issues.

So many variables! Geeesh! lol!

Alyssa

The patterns are unnecessary; and they are so simple that anyone could stop the video and draw them.

Go to interweave.com and sign up, because one type of item they sell is downloadable videos which means no shipping charges, no dvd storage issues, and more importantly - they frequently offer discounts.

On the interweave website, search for Thomas Mann. The only one you need is “Learn to use the jeweler’s saw” video download. You might also like the “Care and use of hand files” video download by Helen Driggs. Be patient, and within a couple of months Interweave will send you an email offering you 30% and sometimes a 40% discount.

Your used files are a wonderful treasure. I don’t think you will need to buy any files.

The coarseness of a file is referred to as “cut”. On the continuum between coarse and fine, 0 is coarse and 6 is fine.

Look very closely at the bare metal handles. Some of them might have the (cut) number on the tang (handle). Otherwise, you can differentiate levels of abrasiveness by using them.

When you determine which ones are the most coarse, you might want to mark them in order to remember. There are threads in the archives about marking tools with numerous things like fingernail polish, paint, vet tape or different colors of electrical tape.

Match the shape of the file to what you are filing. For example, you would use a round file inside of a ring. You’ll figure it out by using the files.

I was surprised when I bought my first escapement file. I thought all escapement files were short, and they usually are, but the only thing you can count on is that the abrasive end of an escapement file is short. The file I bought turned out to be 7 inches long, the abrasive end was 2 inches long and it was way bigger than needle files. In fact, it is heavier and more substantial than most of my biggest files!

Putting lube on the teeth of a saw blade allows bits of the metal you are sawing to get stuck in the lube and collect between the teeth of the blade and diminish cutting capacity.

Some folks lube with spit, and some folks don’t lube. It’s not easy to grasp because everyone you ask will give you a different answer. .

I LOVE YOU! LOL!

Thank you so very very much! So those little ones arent escapement files then, huh? Wonder what they are called or meant to be used for.

I have a lot more files - some are HUGE - seriously do not have the space for them all, and its is a little overwhelming. At some point when I determine I have duplicates I will likely donate them to the local lapidary club as people walked out with ALL their equipment over the years and I’ve been trying to help them get more stuff back - like I donated the bench I got from the shed because I had my dads - couldn’t use two in this house and they needed it more since their’s walked away.

the only files they have left are more like clay files than metal files. But first I need to know what everything is before I hand off some dreamy, to-die-for file that I would kick myself for letting out of my hands because I didn’t know better at the time or something like that. ROFL.

I’ve joined interweave before so I will head off there and go scratch that up! Same for the other you recommended - thank you very much!!

Hey Betty,

Okay so I am super literal to a fault … this is what Interweave has …

-

Mastering the Jeweler’s Saw with Thomas Mann

https://www.interweave.com/store/mastering-the-jewelers-saw-with-thomas-mann -

Metal Artist’s Workbench, Learn to Use the Jeweler’s Saw Video Download

Metal Artist's Workbench, Learn to Use the Jeweler's Saw Video Download | Jewelry, Video Downloads | Interweave -

Metal Artist’s Workbench eBook

https://www.interweave.com/store/metal-artists-workbench-ebook-pdf

2 and 3 look more like what you were talking about and 2 looked the closest according to the title, but the descriptions of what was in them made me pause.

Wait, it’s gotta be number 2, huh? That’s an actual video download. Ugh I need to hit the bed soon evidently I’m getting punchy, lol.

Alyssa, I use regular plain white candles, the reason the blade needs lubricating on it’s sides is to stop it getting jammed in the slot that you have already cut, jamming in the cut slot is mostly when the blades break. the teeth do not need lubrication. Also I didn’t mention that I always use Glardon Vallorbe saw blades as I consider them the best. By the way I have been working in the trade as a goldsmith for over 50 years and was known for my skills in piercing.

These are the saw blades I use.

OMG I LOVE YOU!!! I wish I could just sit and watch you pierce for hours I bet you know ALL the tricks!

I’ve been using Rio Gold Lasers - but wasn’t sure if those were the best … don’t want to go chasing a gimmick when the normal stuff might work the same.

Now isn’t sawing and piercing gold just a totally different beast than it is when working with silver? I wish I could work with gold, but … yeah … not in that financial bracket to be able to afford the material to work with. YET. lol!

Would those blades be the best for silver as well?

And that makes sense about the saw, I didn’t realize that was what was breaking them!

Rio doesnt carry those kinds of blades do they? And neither doe Otto Frei.

Hmmm Amazon does but looks like they might be too expensive for me right now, but it is good to know what I want to aim to get in the future!!!

I use the same blades for cutting gold, silver, copper, and steel. Piercing is something I have always enjoyed, some shaped jobs required me to hold the item to the underside of the bench peg while piercing, like when I was piercing egg shells for Faberge type eggs. This was me way back 35 years ago.

No. 2 on your list is my recommendation.

No. 3 is the same thing except it’s an e-book.

Escapement files are the smallest files, except that apparently they are not always the smallest files. It’s odd, but a good thing to know when buying them.

Needle files come in various lengths.

There are two main differences between needle and escapement files. Escapement files are more finely cut than needle files. That is, a #6 escapement file has more teeth per inch than a #6 needle file. Also the belly, i.e., the cutting area, of a needle file is about the same length as the handle, whereas the belly of an escapement file is about 1/3 to 1/2 as long as the handle.

Escapement files also have handles that are square in section whereas needle files have round handles. Though this doesn’t really alter their function it is useful for telling them apart at the bench.

I draw the letters on the piece by coating it with chinese white which is a white water color. Then I draw the letters with a sharp pencil. It is clamped in a vice so I can go over the pencil lines with a graver. This gives me a very precise line to follow with my saw blade and it can’t be smudged or torn like paper. I prefer the liquid lube because it is less messy and I use very little of it. I get a tiny bit on my thumb and pointer finger and rub it on the blade. Tap con for aluminum is available at hardware stores

Escapement files are a watchmakers tool. They are used for shaping the teeth of an escapement wheel in a watch.

Hello Alyssa,

my teacher told me once…“you use the tool (grit/shape) that will give you the result you want”…he was so good at helping me to see the trees for the forrest!

get the Rio Grande Tool catalog and read it cover to cover! (fun, fun, fun!!!)

basically it comes down to grit…and shape…sort of…

simplistically speaking, think of the range as going from a coarse cut metal file…to a super fine grit rouge on an unstitched balloon buff…and everything in between…

“basically” you have the grit:

ie; the file teeth/cut

ie: the abrasive material like silicone carbide, aluminum oxide, and others

(coarser grits bonded to paper like emery/ sand paper, or bonded into a shape like a grinding point).

(finer grits formed into rubber wheels and points, all the way to grits suspended in oil or water based compounds like tripoli or rouge)

also, the speed of the rotary will affect action…the diameter of the wheel/ buff will also affect…also how worn the paper/ tool/ wheel/ buf is may affect action, etc…

then you have the profiles/ shapes, presented in different ways:

(that are either abrasive themselves, or carry the abrasive)

ie: various wheels and points shapes

ie: various mandrels to hold sandpaper or buffs or brushes)

ie various brushes (from metal fiber to soft fiber)

ie: various buffs (from hard to soft) (the fiber used…stitched is firmer cut than unstitched…yellow treated is more aggressive than balloon cloth…and on and on)

so…you can have a “coarse” 320 grit sanding stick, that is very worn down…that will be less abrasive than a “finer” grit grinding stone…you will eventually be able to “feel” it cutting…sort of…

I would sit down with the files…organize them by length to start…then look at the handle and try to find the cut #…ie:2,4,6,8…and make separate piles for each…

then get some scrap metal and just file the edges…you will “feel” how the file cuts…

so, ie: for the #2 cuts…you might notice that some cut nicely and some don’t…separate or mark them and make new piles…good…dull…

keep the dull files to use to dress up steel tools and such…or on mitering jigs (which are hardened steel and will dull your good files)…

good needle and escapement files can be $10 to $15 bucks a pop…!!!

…there are also less expensive file sets that as small or very short…that are not really escapement files…just short small files…doesnt matter…you use the files that give you the result you want…

(look in the Rio Grande catalog…cover to cover!..you will become the tool expert shortly!!!)

then…take your rubber wheels, stone grinding pints, burrs, and buffs, and systematically play with each group to see what results you get with each…to give you a starting point of understanding what each does…play…make metal “charts” that show the effects…

anyway…just a few thoughts…

Julie

WOW … I hope I can someday reach a tenth of that skill. No, wait, I would adore being that good. Sadly, time will not be on my side on that mission, but if I get closer to your skill and farther away from the skill I current;y am at, I will be happy!

That’s just amazing precision!

Those blades do not seem to be easily available in the US but I didn’t look too hard since it was so late. lol. Hopefully I will be able to find a source to buy them from, and many a selection in smaller amounts as they look like they only sell them in huge packs.

Thank you!