I am looking for small tiny silver screws for cold connections. Does anyone know of a source? Thanks!

This isn’t what you’re looking for, but there is a limited supply from Switzerland of gold (18K) small screws available for repairing Rolex watch bands. You can make silver screws in any size you wish by hand yourself using a screw plate.

Screw plates can either be found on the Internet ( beware of anything from Asia-quality problems) or you can buy one from a watch supply house. Silver is soft enough to make screws using a screw plate easily enough.

Buy a tap and die set and make your own…Rob

I would be inclined to use tiny stainless steel screws like you see in many watches. Just tap the silver pieces to be connected. That way you would have at least one piece in this connection that will be fairly strong. Silver does not make very sturdy screws. Also an assortment of eye glass screws that have coarser threads for plastic might work well in silver.

Bonnie, I have made my own when needed. Not difficult and as a tinkerer I enjoy the nitpickery involved.

Don Meixner

Sent from my Verizon 4G LTE Droid

Reactive Metals has a wonderful selection of tiny screws, bolts, and washers especially for jewelers.

Reactive Metals Mini Nuts and Bolts

(No affiliation – just a fan.)

Whats the best practice when creating a hinge in silver piece.

Silver piviot holes, with stainless screw?

Thanks, Bill - I will give that a try.

Thanks - good to remember the concern about strength. I had tho thought about that.

Hi Don,

Nitpicker alliance. I am in a hurry to get this done, so will use the tap and dye when I have bit more time to nitpick. Thanks! I look forward to making them myself.

Hi Bruce,

Any chance of a description of the piece you want a hinge for?

As hinges in small things like lockets, vinaigrettes , snuff boxes

cent/perfume bottles and bracelets etc are a real pain to get right in the 1st place and 2ndly when they need repair.

Never use steel pins, stainless is ok but there normally in nickel brass, hard and good self lube in silver .

Await your reply.

Ted

The screws used in Swiss watches use a thread roughly to the ISO standard, which America does not follow except on metric. Older Swiss watch screws use entirely arbitrary standards, so you often have to retap the screw to make it fit the threads.I like the idea of eyeglass screws. Their threads are coarser and it is easier to find taps for them.

If anyone wants the detailed step by step process to make slotted 18k gold screws at the bench email me: thejewelmaker@gmail.com

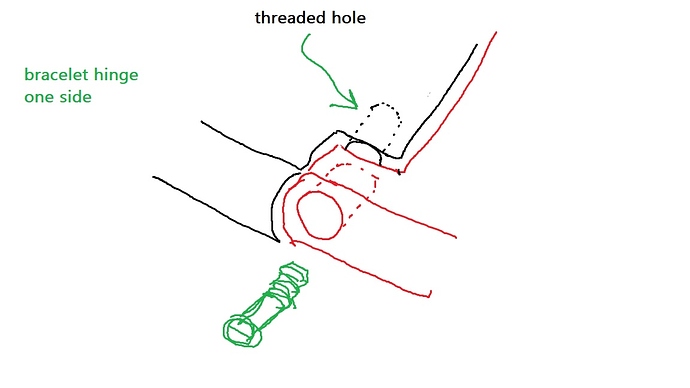

Thanks here is what I have in mind, could use bolt or could put in a pin and solder to outer piece maybe. Don’t know whats best approach for this? If I use bolt whats the best way to keep bolt from loosening(I may have acess to threaded back end of bolt after I install it so maybe deform the end to lock it?), and whats best type of bolt? If a pin, what material that would wear well and that could be soldered to silver? Would a press fit pin work with this?

The best solution is a screw, with out doubt. an interference driven pin will work but a pitta to repair. S/steel is best for this screw. you may know, folk will go swimming and hinges in ordinary steel will rust and lock up the hinges. Secure with a tiny bit of superglue on the thread. Just heat to dismantle.

Brass is also ok but too weak in the size? you need to use.

the fixing could be round head, countersunk may be difficult to make. If you cant hide a fixing, one makes a feature of it.

Ted.

Thanks Ted, When you talk about the fixing being hard to make, are you referring to the head of the screw. Meaning that a screw for this would be normally custom made.?

I would I guess be hoping to find an appropriate stainless flat head screw and tap, off the shelf some where. I would think some thing would be available.

The screw size is determined by the thickness of the hinge metal, which you havnt mentioned. In any hinge design you need to consider the way the customer will use the product. Most are quite clueless and will abuse their jewellery, and when it breaks blame the maker.

So if for example the silver is 3mm thick, the screw needs to be no more than 1.2mm diameter. A weak solution to this question. Also whats the overall width?

Need to know!!

you cant use flat head screws as they will cause injury to the skin of the wearer. Round head are sort of ok but c/sunk set in is tricky to make so the screw is set flush with the side of the hinge.

hope you follow.

You may need to redesign the whole hinge area to ensure its up to years of wear.

Cant help more without the actual dimensions of your planned product.

Its a common problem here , folk have little idea of what info needs to be mentioned by the questioner to us who are the technical guru’s on what works and what doesnt.

Read my last post to Rob re his press design as an example.

I regularly cannot help folk because they cant be bothered to provide the tech info needed, not that may be the case with you.

Ted.

Most hinges of this type done in jewelry are just done by a rivet. You put a pin threw and then tap on the ends with a tiny ball pean hammer until you form a head on each end.

That is certainly true, but if the hinge is say 20mm or more wide, the asker needs to drill a 1.2mm hole that deep through the male part of the hinge. not easy in a bench jewellers scenario.

Thats why hinges of this width are made of multiple pieces of tube solder on to both parts.

Ted.