Thanks for those reply, This hinge is narrow one on each edge. So a rivet could be a solution. What metal is normally used for the rivet, silver? Flat head screw are always counter sunk that’s what their designed for, not sure how they would be a problem for the wearer. I think its all going to come down to designing the parameters of the hinge to the strength of the silver, (strength of threads, and hinge pin hole) as its a relatively soft metal, and at this point I am unfamiliar with it, as most of my work has been sculpture in bronze.

There are a few difficulties with your idea.

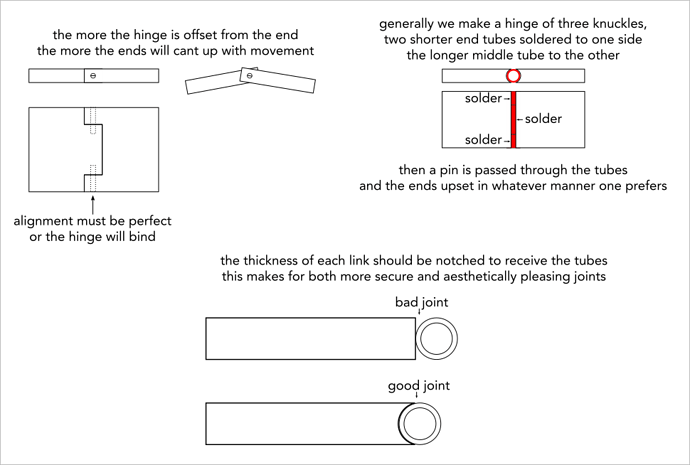

First, unless you have a machinist’s setup, like a mill with a digital read out, you will have difficulty getting the tapped holes to align perfectly. If they are out of alignment the hinge will bind when it moves.

Second, the more the center of rotation is set in from the edge, the more the links will tend to cant out when the hinge moves. This is why watch bracelets have links with rounded end profiles. So that there are no sharp corners when the links move.

Generally hinges such as this are made with tubes soldered to the ends of the links. Then a pin is passed through and the ends upset.

Thank you for that Elliot.

Thanks very much for the good suggestions. I will make my own when I am not pressed for time. For now I have ordered some from Reactive Metals. Your help was great!!

Reactive Metals in Arizona