There’s just got to be a better way! Does anyone have a better way of getting rid of swarf after filing wire? Geez, it’s just so time-consuming! I use a graver for this task. (I was using my father’s old pocket knife, which is still extremely sharp) I keep looking around my shop in the hopes that something will magically appear to make this job a “JOY,” but so far, no luck. Any remarkable ideas out there? You’ll be my new hero! I’ll even whittle or maybe knit?.. you a red cape! (In the interest of transparency, I neither knit nor do I whittle… but hey, who knows what the future holds, right? I mean, you’ll still be my Hero! and that counts for something…)

Thank you for reading through all of this! You get 5 *'s just for that amazing feat! Brilliant!

I use a graver as well. I try to look at it as a task that needs to be done. Like other boring tasks. I try to see it as a meditation type thing.

Maybe I misunderstand, but in my world swarf is the loose fragments from a drill bit or similar, you are refering to the sharp edges lifted from said drill bit or graver?

Burrs I think is the word I would describe it as.

I think of swarf as that which is left over after wet grinding or sanding. What you are describing sounds like the small burs left after filing. I use a sanding stick to remove them or, if there is a larger area, an abrasive wheel or even a lapidary belt on an expansion wheel. You can also buy a hard, sharpened steel bur removal tool, but I find them a bit overkill…Rob

If you’re referring to the bur that’s left along the cut you might consider changing to a finer saw blade size as that can make a difference. The suggestions you’ve received above for clean-up are great. If there’s a lot of piercing I sometimes use a sanding strip that I can thread inside of smaller areas which works really well. There’s a previous thread that touches upon how others approach clean-up.

Gerald is correct in that this is one of those boring tasks that needs to be done. Unfortunately it’s also one of those tasks that can make or break the presentation of your finish piece.

Pam

I just bought some Mitchell’s cord and will try it out on the removal of small amounts of metal in hard to reach places like smaller piercings and around prongs…rob

Re: Filing wire. I’m a little confused. Are you cutting wire and leaving sharp edges? If so I use a cup burr on the sharp ends of wire like on earring posts.

I’m confused as well. Can we see a picture?

After I cut a piece of wire to be an ear wire or post, I round the end with my pulse arc welder. It leaves a nice round smooth surface. You can adjust the size by how much power you set the welder to deliver or how many times you weld it. Larger pieces of wire are first filed square and then any burs are sanded off with a sanding stick or file depending on the size of the wire. If you leave them, they interfer with a solder joint and are just unsightly. This is basic bench work and something that you should learn early in your career as a metal artist…Rob

My take on the post was for wanting a good way to remove metal clogging the file. Which might be mistaken of course.

I have a nice, very fine hand file (#6) that is clogged with metal, is too fine to de-clog that I know of. I wonder if a brass rotary brush in a flexshaft would work to clear file cuts, but have not tried it myself.

The original post was more venting frustration - which I can well relate to for so many things - than information. More detail would be good, but sometimes it helps to just go !#$&#! to a sympathetic ear, and I do relate.

Neil…I went back and re-read the OP’s post and I think that you are right. We all got off on the use of the term swarf. I don’t think that we should ever regret these discussions as there are a lot of people reading them and a lot of good general information is passed on even if you don’t have a swarf problem…Rob

Neil

For those difficult file cleanings, just flatten the end of a nail fairly thin with a hammer.

Bend it. Square it off and then run it along the file groves. That will make little teeth on the cleaner that dig out the filings. Little nails for little files, big nails for big files.

Dave

To help keep files from clogging in the first place, clean the file well first, than rub it with soapstone “chalk”. Soapstone sticks are usually available in welding supply shops, or Google for online suppliers. To clean files out, I use a piece of flattened brass wire.

I have real trouble with working small. I like to limit the small hand work I have and I am always looking for a work around if I can find one. That said I make all of my earring wires. I cut some 20 gauge round wire to 2.75" with a pair of flush cut pliers. I toss the loose wires in a small shot tumbler and let them run for 1/2 a day. I dump them and bend them into the right shape, tap to flatten the back of the curve with a light hammer and put them to work. The wires are nice and shiny and look pretty good as well. No complaints from any customers.

Don

Clarify the DREADED SWARF

So, I wasn’t venting (#%*%#) though I though I do see where some may have thought that. But no, I was discussing “SWARF” those horrible bits of silver that remain once you’ve finished sawing either sheet or wire (in my case it’s usually) silver.

I definitely should have thought about using a smaller or, I should say a thinner saw blade. I always forget to switch blades that’s why I have two saws… and yes, they do in fact, both presently have the same size blades in them! I know! I KNOW ![]() I yell at myself all the time but nothing ever changes! (seriously, I’m constantly saying “Teri! What’s the deal! Is it REALLY THAT difficult to change your blades! Geez! You’re lucky you’re your own boss”!) I mean, don’t you? Come on!

I yell at myself all the time but nothing ever changes! (seriously, I’m constantly saying “Teri! What’s the deal! Is it REALLY THAT difficult to change your blades! Geez! You’re lucky you’re your own boss”!) I mean, don’t you? Come on!

But, I do have some good news! I may have solved my problem! I came up with something that will remove the swarf! And it was just sitting there! RIGHT THERE IN FRONT OF MY FACE THE WHOLE TIME! IT WAS! It was DANCING THE BOOGIE WOOGIE…. IT WAS TAP DANCING ACROSS MY BENCH…. IT WAS, quite literally DOING THE CHA CHA down my flex shaft! That’s when IT HIT ME! (and you just got lucky because I ran out of dances…) I picked it up and said out loud to myself… “Can it be? Could this be the one? Is it possible? Am I dreaming? Dare I? No! It can’t really be that simple? Or can it? I’m doing it! YES! Gimme some scrap!

This is when my simple BURNISHER was no longer my simple BURNISHER! No, it was my SWARF REMOVER / BURNISHER henceforth known as swarfubrinsher! Or, better yet The Swarfubrinsher! Soooo Cool! Ya think? So, you don’t really have to call it that but just remember, you saw it here first and when I’m rich and famous… well you knooow! Just saying…. All fun aside, it does work and I’m so happy to have it in my arsenal of tools that have multiple uses.

And that ladies and gentlemen, was the beginning of a true love story! The birth of “the swarf remover” /burnisher! And this folks, this is a true story! Whoda thunk it! A BURNISHER. You know, the one that you bought a hundred years ago that came with the rocker to set cabochons in bezels? Yep! THAT burnisher! And… IT WORKS! I hope it works for you. Now, I’m off to learn how to clean my files and how to vent using clean words! Yea me! But first, thank you all for taking the time to answer my question. Even those who didn’t get me! Not to worry, I’m surrounded by people who don’t get me… my #1 fan still doesn’t get me and we’ve been married for 33 years! I LIKE it like that! It keeps things interesting. And, if he’s lucky he’ll get another 33! Cheers!

p.s. Oh, and I’ve tried some of the other things that were mentioned in the posts but the drawbacks were that most of them removed metal. And of course that’s the last thing I wanted. Even using the burnisher I have to be careful when cleaning up the ends of wire. Just to make sure not to push the corners (square) in or (round) edges. But I was on a mission!

Now if I could only find a way to get my bed made in the morning for me I’d have it made! Ha! … get it?… get it made…have it made! ohhh… I know.. never mind! ![]() no wonder no one gets me! Love!

no wonder no one gets me! Love!

Ah! you also mentioned a pen knife earlier…i had thought of a potentially related swarferator…a 3 sided scraper…but i wasn’t sure if it was too big…i think that is one of its actual jobs…

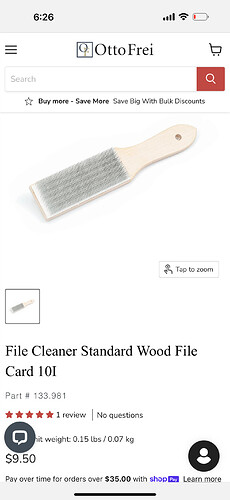

oh! and otto frei seems to carry many versions! including smaller ones than the one i was thinking of!

have a look

here is the one i was thinking of

and here is a whole selection! oh my!

and deburring tools…i forgot about those…

julie

…i think what you are wanting to do is called de-burring…?

julie

Heavens to Betsy! I seem to have created quite the misunderstanding here… of course I was under the impression that everyone called the little annoying shreds of silver (usually the norm in my shop anyway) that haunt the ends of my metal after I saw, SWARF! Maybe it’s just a Midwest kind of thing… like Heavens to Betsy… or does everyone claim that one? ![]() Thus, I stand corrected. I also apologize for the confusion. Regarding the saw blades, as a rule, I generally like to have 2 to 3 teeth on the metal when sawing so, I think that I’m using the correct size saw blades. I’m not getting a “ton” of Swarf but just enough to get in the way of getting that perfect join. I’m not anal… just a perfectionist!

Thus, I stand corrected. I also apologize for the confusion. Regarding the saw blades, as a rule, I generally like to have 2 to 3 teeth on the metal when sawing so, I think that I’m using the correct size saw blades. I’m not getting a “ton” of Swarf but just enough to get in the way of getting that perfect join. I’m not anal… just a perfectionist! ![]() Actually, when I was first learning I had a teacher who was waaaay over the top anal and demanded that “ALL SWARF MUST BE REMOVED” now, read that again with your chest out and in a manly voice and think of a woman with three black hairs, each approximately 2/3rd’s of an inch long on her chin and great big man hands! Believe me, when this woman spoke, she bellowed, and you know what? We listened! Doggone it! We LISTENED AND WE LEARNED! By gosh by golly! We are all probably STILL working on that darn Swarf today! She was gruff but, she was definitely effective and a rock star as far as I’m concerned! So anyway, I was so grateful that evening when I was once again facing those itty bitty pieces of silver, bound and determined to figure out, that night (!) a way to clean them up without losing metal! And wouldn’t you know it, my burnisher was sitting right there! It had ALWAYS been sitting RIGHT there! But, as we all know in this wonderful thing we all call life (no confusion here… right? Well, so okay, some may call it a journey, and hey, I sometimes do too… when I’m waxing poetic.) Alas, tonight it’s all about the swarf and I believe that we can all agree, there is nothing poetic about that to wax on about. So, again, I do appreciate all of your helpful feedback and support and I apologize to those of you who had no idea what I was talking about. I’m quite used to that too. I’m no longer weirded out by the constant strange look on my husband of 33 years face. I’ve come to accept it as his “What ARE you babbling on about NOW? You’re speaking in your nonsensical language again. Ohhh…. do I love that man! And each of you too! Sorry, I know it seems like my sentences all appear to run together and my thoughts are bouncing around but, it’s late and we’ve been up remodeling our kitche for the past two days and this is the third night! I’m not even sure if I’m really writing this… I could be having a waking dream… these things do happen.. at least no one is naked! To my knowledge… uh honey… where are you.. Rob! Are you on the laundry room.., BETTER GO!

Actually, when I was first learning I had a teacher who was waaaay over the top anal and demanded that “ALL SWARF MUST BE REMOVED” now, read that again with your chest out and in a manly voice and think of a woman with three black hairs, each approximately 2/3rd’s of an inch long on her chin and great big man hands! Believe me, when this woman spoke, she bellowed, and you know what? We listened! Doggone it! We LISTENED AND WE LEARNED! By gosh by golly! We are all probably STILL working on that darn Swarf today! She was gruff but, she was definitely effective and a rock star as far as I’m concerned! So anyway, I was so grateful that evening when I was once again facing those itty bitty pieces of silver, bound and determined to figure out, that night (!) a way to clean them up without losing metal! And wouldn’t you know it, my burnisher was sitting right there! It had ALWAYS been sitting RIGHT there! But, as we all know in this wonderful thing we all call life (no confusion here… right? Well, so okay, some may call it a journey, and hey, I sometimes do too… when I’m waxing poetic.) Alas, tonight it’s all about the swarf and I believe that we can all agree, there is nothing poetic about that to wax on about. So, again, I do appreciate all of your helpful feedback and support and I apologize to those of you who had no idea what I was talking about. I’m quite used to that too. I’m no longer weirded out by the constant strange look on my husband of 33 years face. I’ve come to accept it as his “What ARE you babbling on about NOW? You’re speaking in your nonsensical language again. Ohhh…. do I love that man! And each of you too! Sorry, I know it seems like my sentences all appear to run together and my thoughts are bouncing around but, it’s late and we’ve been up remodeling our kitche for the past two days and this is the third night! I’m not even sure if I’m really writing this… I could be having a waking dream… these things do happen.. at least no one is naked! To my knowledge… uh honey… where are you.. Rob! Are you on the laundry room.., BETTER GO!

Thank you! I’ve been reading about chalking files and was trying to find out what kind of chalk to use. I just bought a new set of files that haven’t been used, yet. I ran across this thread just in the nick of time. I was going to ask about chalking files if no one had already mentioned it.