morning! i’m in desperate need of tool suggestions for reaching inside very tight spaces. i posted about this once before and you were all so helpful with tools that could get inside the seat of the stone area, but i’m still having trouble in areas where i want to work the grits from coarsest to finest and i can’t find a single tool that can reach them all without adversely affecting/flattening another area. suggestions for polishing like using a toothpick in the flex shaft charged with compound is great, but i still haven’t been able to sand the areas in order of grit before getting to that point!

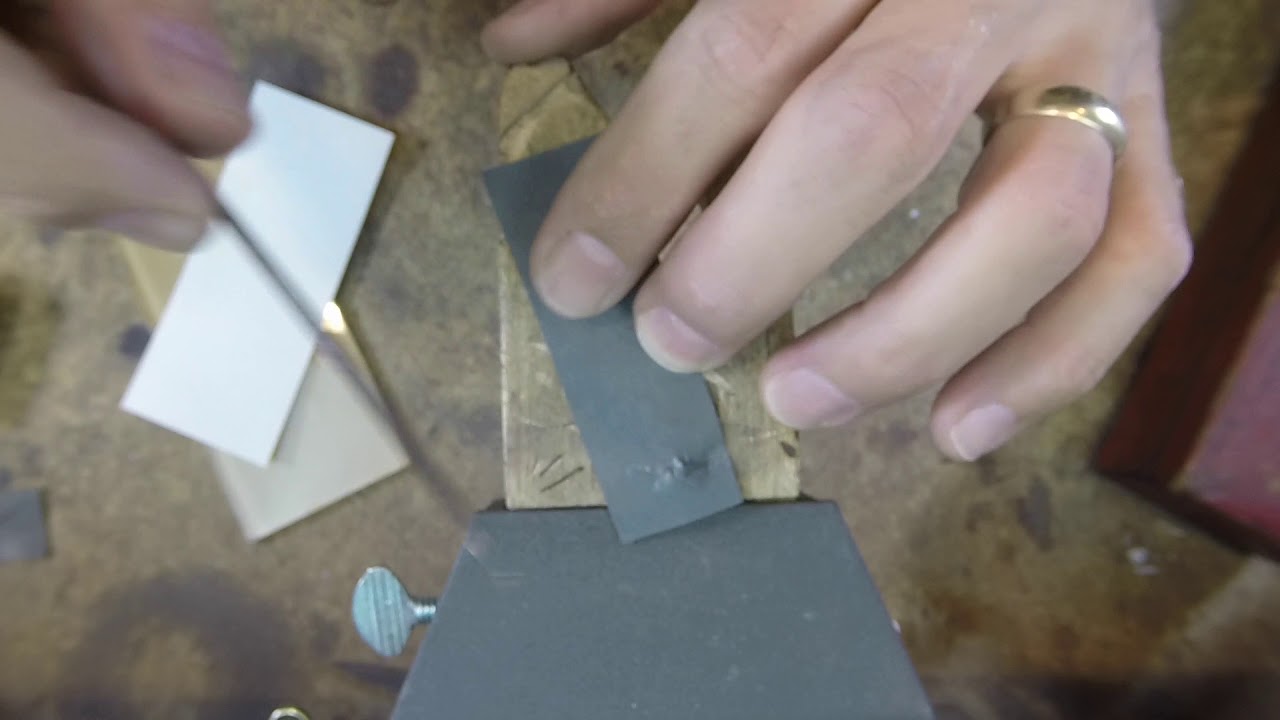

i’ve tried sanding wheels and they’re great since they’re flexible but i end up flattening parts of my curved piece. if i use emery paper on a split mandrel that is best for running around the outside of the curved piece but it’s too thick to fit into the tighter areas. i’ve tried radial discs but those have actually left indents in spaces, you can see the waviness of the “P” charm where the black arrow is pointing, that happened when I was using a radial disc on the parts of the charm i’ve pointed to in red! I don’t even remember what i used that did this to the “W”, but i simply cannot get to the inside portions of this charm and when attempting to, the part i’ve pointed to flattened out in the process.

these charms are printed from CAD files and part of the issue is the growth lines from the 3d print. i feel that i have to start the sanding process at a coarser grit to get these out. i’m using a casting company so don’t have access to the resin before it’s casted to do any kind of finishing work on that first. i’m just at a loss as to how people get into these tight spots! i keep wishing i had emery paper rolls the size and shape of a sewing needle.