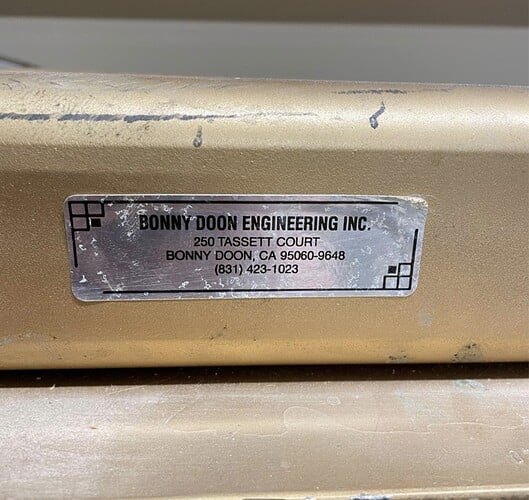

I was lucky to be able to buy a lightly-used, very early Bonny Doon press. It’s early enough that the return springs aren’t enclosed in the side pillars.

I’d love some information, if any of you BD enthusiasts can share.

There’s no manual with the press, but except for the springs, it looks a lot like the Classic. However, we think it’s much, much heavier. The frame is 33-1/2" tall, 16" wide, and 9" deep, with 12x8x2" solid steel platens that extend 1-1/2" front and back (past the edges of the frame). It’s made of welded 1/4-in wall 3x3 tubing. It came with a PT 1/4HP pump.

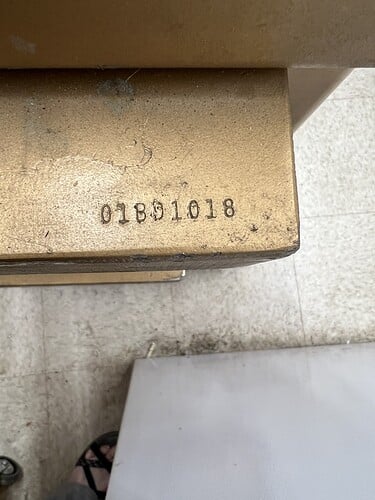

I haven’t been able to take a close look at the ram (to look for identifying info), but the seller said it’s 20T. My husband thinks the frame looks way larger than the current “Classic” and as if it’s designed for a much higher load. I’ve read many posts suggesting that’s how Lee Marshall built them - design for 50T and configure for 20T.

We’re probably not going to be able to tell how much it weighs - it’d break our scale - but we know that two strong guys weren’t able to “power lift” it off the floor. We’re guessing it weighs over 200 lbs.

If anyone knows where a manual for this might be downloadable, I’d appreciate suggestions (I’ve already struck out on Internet Archive, Bonny Doon, RioGrande, ManualsLib, facebook groups, and other obvious suspects).

Thanks

Caroline Rumsey