I wrote an article about rolling mills for SNAG’s Metalsmith magazine about 5 or 6 years ago. I interviewed a pile of people including jewelry artists who used rolling mills, and folks who make them, Matthew Durston, owner of Durston, Tony Aizenman, owner of Pepe, and Sean Seo, owner of Best Built.

They all said pretty much the same thing. Keep the rollers clean and oiled and to wipe the rollers before and after every use. A light oil like 3 in ONE is often recommended as the best oil.

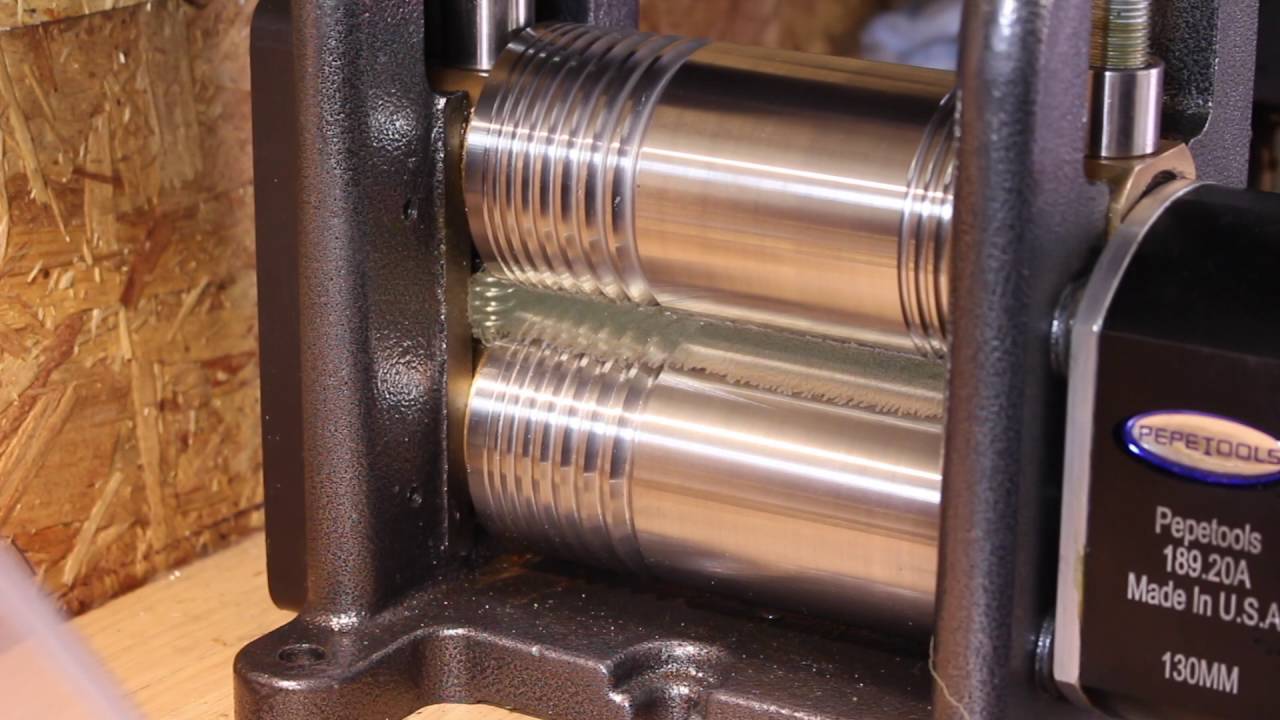

Here’s a great video from Pepe about rolling mill maintenance:

Rust is different from carbon steel staining or discoloring. What to do about rust depends on how bad the rust is. If it’s just a little bit of rust, then a fine abrasive will remove it. You might need something more abrasive than Simichrome to remove rust. If it’s a lot of rust, then the rollers will have to be removed and sent to a specialty machinist to refinish them.

Many people don’t know that high carbon steel rolling mill rollers aren’t tempered consistently throughout. The center of the rollers are soft/annealed and the outer surface is hardened. That allows for the rollers to kind of have an internal shock absorber. Otherwise the rollers can crack over time. Tony Aizenman told me that he lost a whole pallet of rollers once because they weren’t tempered correctly.

The varied tempering means that you can only totally resurface rollers at a machine shop so many times before the you will compromise their integrity.

Steve Midgett, the mokume gane expert, told me a great trick that he uses on his rolling mills. He wedges in oil soaked foam at the top and bottom of the rollers in between the frame and the rollers. That way his rollers are always cleaned and oiled after every use.

I had an old unmounted Cavallin rolling mill on the floor of my studio once (which is an old shed). There was a flood with spring snow melt that I didn’t catch for a bit. The rollers got very rusted. I had to pull the rollers and send them to a machinist that Otto Frei used. Now it’s good as new, but it was quite an ordeal. My advice is don’t do what I did and keep up on the maintenance.

It sounds like you caught your mill in the early stages of rusting Julie. It should be an easy fix and just a good reminder to keep up on regular maintenance.

Hope that helps!

Jeff