This is wonderful advice. I’m writing down every tip and trick you listed. I have some questions for you if you don’t mind. Could you share the contact information or website of the machine shop that Otto Frei uses? I’m looking for a good machinist who knows how to do specifically jewelry equipment and tools, it just seems like some good info to have on hand just in case, yanno? I may be sending my rollers off to one if I can find a good one because honestly my carpal tunnel is not loving me sanding and polishing these things. Also, you said you wrote an article about all of this. Would you be able to share either a link or the article itself here that you wrote? I would love to read it in full. Thank you for sharing your expertise, it’s much appreciated!!!

El Niño cycle. The rest of the country suddenly gets dry because all of the rain ends up drowning us here in Colorado. I hate El Niño years. I’m only half joking when I say I’m considering trading in my car for a boat to get to and from the grocery store. Seems like it happens about every 7-8 years. The last time this happened was in 2015. Didn’t see the sun at all for four months, and half the city was under water. That’s why I’m on this thread right now, the humidity is killing my rolling mill and tools.

I shipped the rollers to Otto Frei and they set things up with a machinist that they used. It was kind of a torturous process actually. The machinist moved at a snail’s pace and it took him at least 6 months to finish the job. I had push Otto Frei to push him, which was awkward. I never got the machinist’s contact info.

What make and model of rolling mill do you have? That info would help with advice for next steps. Also just so you know, some rolling mills are easier to take apart and remove the rollers than others.

As far as the rolling mill article goes, it was the Fall 2019 issue of SNAG’s Metalsmith Magazine. Because I wrote the article for them, I don’t actually own it, so I’m not sure how to share it?

Jeff

For me, I aspire to not over think or get too stressed out about rust. I’ve surrendered to its existence and just try to keep it at a reasonable level.

I know that this is different from how most (including me) have been taught, but I only keep a few of my steel tools at a mirror finish. In fact, I think my only hammer that I keep at a mirror finish is my planishing hammer. I keep all of my forging and chasing hammers and stonesetting punches in a 400 grit satin finish. I’ve found that having a bit of bite to those tools really helps my accuracy. Polishing out a 400 grit hammer or setting punch blow is pretty easy to do.

Again, many will disagree and that’s no problem. Everyone finds their own path in moving metal. That’s what works for me.

I do my best to keep my rolling mills in perfect condition (I have 3), but I’ve found that perfection is elusive, (especially in a humid climate) so I shoot for pretty good.

That said, rust is like dry rot in a house. It’s best to get rid of it as soon as possible. The title of that Neil Young song, “Rust Never Sleeps” is very true for metalsmiths.

Jeff

Thanks so much!

Some perspective might help here. I don’t look at a lot of youtube or similar videos, but when I look at one where a rolling mill is being used, the condition of the mill varies a lot from video to video. I would expect that someone posting a video would make sure that their tools look good, at least to them. Maybe we should all post a picture of our rollers after a typical day in the shop. We might find that we are making a lot out of nothing. What one person might call rust, another person might call a stain and another wouldn’t worry about it at all. I am not advocating that we tolerate real rust on our tools, I do a lot to avoid it, but I also don’t spend a lot of time during the day avoiding it. If you want to see an example of someone who really spent a lot of time avoiding rust, look at the late Jeffery Hermans website if it is still up. Just a thought…Rob

Rust. Oy! We live in the Pacific NW where it rains pretty much all of the time. Prevention is key. All of my stakes, hammers, steel blocks, dapping blocks, dapping punches, etc. are all covered with car wax to keep the moisture out. As for our rolling mill…

I keep soft sponges wedged into the top and bottom of our rolling mill. They stay there all of the time. Those sponges are soaked with 3 in 1 oil. So as I roll the oil soaked sponges oil and clean continuously. I also keep the mill covered with an old cotton pillow case when not in use to keep dust and any air born debris off of it.

As for cleaning the groove I use a cotton Q tips soaked with oil and with tripoli or bobbing compound rubbed onto it. Q tips are pretty fragile so it can take several to do the job. After be sure to use more clean Q tips soaked with oil to remove any compound debris. The only time I have needed to do this was on the rolling mills at a crafts center I used to teach at. Also about once a month I would use a 1/2 -1 inch wooden dowel with very fine 0000 emery paper or rouge paper, again with oil, wrapped around it. I use a long strip of emery because the hard metal on the rollers wears the abrasives away. I close the rollers down and roll away.

PS: When the sponges get worn and dirty be sure to send them in with your refining. You’d be amazed at how many fine flakes of metal are in them.

Jo

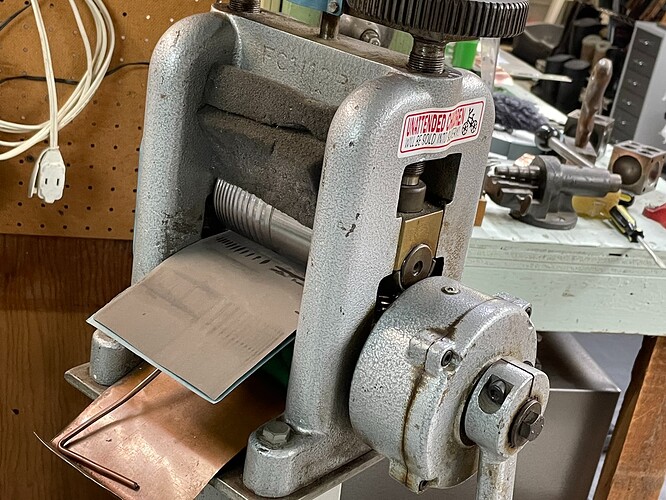

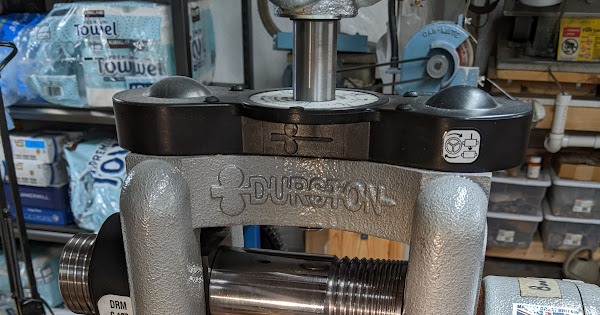

Following is a series of pictures related to my mill. I just did maintenance on it a couple days ago, so you can still see the shine of some oil. You can also see my maintenance kit that includes a polishing cloth, sponge, piece of pipe and bag with a tube of simichrome polish, cloth glove and a small rag. I forgot the 3 in 1 oil can. Finally two pictures that show how I polish the upper and lower rolls. It is just like polishing men’s shoes. My shop is very dry. Right now the RH is 35%, so I don’t do the permanent sponge application that Jo has shown. I do keep a sponge soaked in oil and run it between the rollers from time to time. My Durston mill is 10 years old and my economy mill is probably 15 years old. They are made to last a long time with a little bit of care. One additional comment. I have been watching the Potter People FB page for some time and have also purchased four of his print plates. They are a lot of fun to use and open up a new design area. One caution is that you can get the rolls too tight trying to make a pattern transfer. This tightness could result in damage to the gears that drive the rollers and possibly even the rollers themselves. Be careful if you are roll printing. I would rather have a bad print than a damaged gear…Rob

Um, Jo, as per the sign on your mill, what happens to unattended children? ![]()

Neil A

(It might be best to not reply.)

My Durston mill didn’t come with that warning. Kids are safe in my shop as long as they just don’t pound on my anvil with a steel hammer. If they do, all bets are off…Rob

I’m going to squish oil soaked sponges into my mill this weekend. Look at those rollers! So shiny and perfect!! That looks like a Cavallin mil, which means it’s probably at least 30 years old. Excellent job in keeping the rollers in such sparkly condition Jo!!

Jeff

Great idea Rob! I’ll try to shoot some rolling images today and post them tonight.

Jeff

Hi,

Ok, i was able to order some Autosol, and Flitz metal pilish…

here is a photo of my mill rollers after just rubbing with oil on a Cotton swab…

julie

Do you remember what you were rolling before this appeared?..Rob

I am careful with my Durston mill and do monthly maintenance on it. More often if I have to. The same goes with any polished surface I have. Hammers, mandrels, etc. I am not at all concerned about mirrored finishes but I do worry about any transferable scratch, divot, or dent.

I put a piece of Ieather charger with compounds in my palm sander for doing flat surfaces like my blocks and anvil to clean them up. I do strips of latigo or leather boot laces in the grooves on the mill and then the Shoeshine moves in the grooves as well as the flat surfaces. I have a some staini9ng that I can’t buff out but as I said I am not worried as long as it doesn’t leave a mark.

Don

Julie,

Your Rolling Mill looks like it has some real age to it, so if there is just as little rust on it as it appears, you’re doing really well with it! One of the Trade Shops that I worked in had a Rolling Mill with the Green Plastic on top like yours and it was pretty old then (around 15-17 years ago), so your’s is in Great Shape!

Jonathan

Hi,

well, i have only been rolling down forged rods into square wire…we did have a super rainy season awhile back…i made a civer out of an extra A/C cover…it is nylon, coated with pvc on the inside…

julie

You might think about not covering it or using a cover that is breathable so that you don’t trap moisture under it. The same thing goes for AC condensers. You want to protect them from falling ice, but you don’t want to make a home for mice that will chew the wiring…Rob

Hi Jonathan,

yes! it is quite old! it was old when i bought it 15+ years ago! A jeweler friend was retiring…

It is a Cavallin

Julie

Good point about a breathable cover. This is why I use an old cotton pillow case on my mill. Before I learned Jeff Herman’s trick of using car wax I used to keep all of my hammers covered with my husband’s old athletic socks, and the stakes and other metal forming blocks etc with old flour sack towels. My shop used to look like a home for lost schmattas. schmatta - Jewish English Lexicon With the car wax the dust and debris slides right off with a puf fof air or a feather duster.