I may have asked this question before, but I can’t find it. One of the hardest steps for me in making jewelry is marking it. In addition to my initials and a sterling or 14K mark, I add a serial number and size stamp as long as it doesn’t deform the piece or make it unstable. I spend more time marking some pieces than I do polishing them. This is partially because my hands cramp up and I can never get the number sequence right (dysgraphia). I am curious if anyone has experience using the new laser markers that I see in my FB feed to do this type of marking. I could also see it being useful to transfer a design to metal that will later be engraved, chased or in some other way applied to the metal. I work mainly in silver and I know that silver is a challenge for lasers. Thoughts appreciated. Thanks…Rob

I’m curious if you mark your pieces before forming them or do you prefer to mark them after they have been formed into a band?

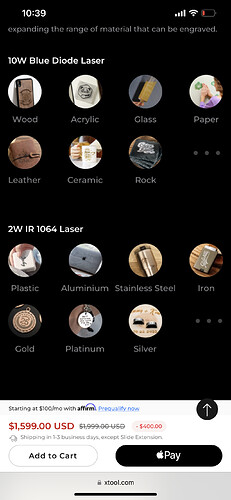

You’re really looking at an IR laser (1064nm) rather than the blue laser style. The blue lasers can mark stainless steel easily but for other metals it needs a very high amount of power to do it.

The xtool F1 with the infrared diode and paired with the rotary tool would be quite complete for marking silver and gold.

I’m saving for the D1 40W and an IR add on as I want to use it for multiple purposes.

I mark after polishing, but before shaping, so they are flat…Rob

What would I need to also be able to mark and cut heavy paper for roll printing? Thanks, I don’t know much about lasers…Rob

Hi,

here is an interesting review article…i think i was more curious about the XTool F-1 in the pop up ads!

julie

Rob, some years ago I got curious and bought a kit laser from Darkly Labs in Australia.

It was a 4 watt laser, reasonably powerful at the time, and was able to burn designs on paper.

However, it used long rubber belts to drive the head, and I was never able to get the tension on the two belts adjusted properly for accurate tracking.

You will need a lot more power than 4 watts unless all you do is work on paper, and whatever you buy, be sure the stepper motors drive worm gears, not rubber belts.

I believe Darkly Labs corrected that issue in later versions. That did me no good, but they are a reliable company.

Good luck with it and if you find something that works please let us know.

Neil A

P.S. If you buy something and it does not come with good software, Cut2D Laser by Vectric is good. Vectric is a great company and produces astoundingly good software.

They are Australian as well.

Neil…Thanks!..Rob

Anything above 5W should do the job - 10W visible blue would do the trick - not 100% if the IR can cut paper but I believe it should be able to - the physics says it should (in my understanding at least)

I have kind of zeroed in on the xTool products. Looks like I need an IR/Diode combination which they sell. I am totally ignorant of the software. Is it fairly easy to use for the purposes that I am contemplating? My guess is that I will have to buy yet another computer since I currently just use chrome OS machines for general use and an old PC to run my label printers. xTool is offering some heavy discounts for Prime Day. Thanks…Rob

It has been a nightmare trying to find a way to talk to someone at xTool about their equipment and recommend something that might meet my needs. I joined what is titled their “official” FB group and asked the same questions that I have been asking here only to have my post bounced because I included my website. I am surprised that they sell anything…Rob

Customer service is last on the priority list for these types of companies.

Well, I have resurrected this search. I recently found out that Stuller techs had done a lot of research on small marking lasers and have settled on the LaserPecker 4. PMC has followed their lead. They both offer a LP4 delux package for around $2,500 that includes the laser, a rotation table and a slide extension. There was a recent firmware upgrade to the LP4 and it has apparently caused all kinds of problems for LP4 users. Again, I am just interested in replacing the stamping that I do on the inside of my work with laser marks. I would also use it for engraving, chasing and piercing layout and, hopefully, cut out heavy paper and light card stock designs that I could use for roll printing. It appears that, at least the LP4 can do all of this and I presume the xTool as well. If anyone has recent experience with either of these lasers I would appreciate hearing it. I know about fiber lasers, but I am not interested in actually cutting metal, just marking it. Thanks…Rob

You might try asking on Reddit as well

Hi Rob,

i am curious to know how deep the engraving can be…i notice that some laser engraving is rather light…ie: i have seem silver frames engraved at keepsake stores that are very light…when you angle the frame, visibility is lessened…

in terms of marking your jewelry, would it be while it is still in flat form?

as far as the jewelry marking goes, you could use something like a new hermes manual drag pantograph…i have one and the “cuts” are deeper than laser engraving…i am just thinking that if laser engraving is used for your special jewelry marking system, it might wear down/ off…

there is also a pantograph for inside ring engraving…that might work on your bracelets…?…after rounding…?…

the downside to the inside ring engraver is that the font style on the dials available are limited…whereas there are more (vintage) font sets available for the flat style pantograph…

i stumbled upon my purchase (for a good price) when a friend was selling his studio tools…it was in a lonely corner, cover with a blanket…i kept saying “um, no”…and then “ok, how does it work”…i fell in love with it and it has had a new lease on life with me…although it has been sitting idle for the last few years…polishing imaculate mirror finish sterling silver disc charms wore me down…i tell it that it is just temporary!

other, less expensive generic brands are also available…

julie

Julie…I am only looking to mark my jewelry. To actually remove metal, you need a much more expensive fiber laser. According to the techs at Stuller, the marks are fairly permanent. My work would be flat when it is marked. Additionally, I can use it to lay out engraving, chasing, piercing and even artful lines. I have been asked to engrave small maps. The cost of actually engraving them would be more than anyone would want to pay, but using the marking laser, it could be done fairly quickly. The Stuller Tech also confirmed that it will cut patterns out of paper and card stock. All in all I am happy with what I have learned…Rob

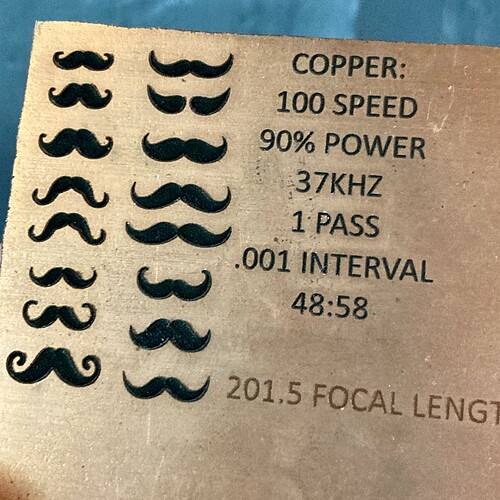

Stuller has recently taken on the Laser pecker 4 (LP4) and sell it as a package with a table that extends the size of the work table and another table that allows it to do round objects (rings and other things). My guess is that Stuller being Stuller did their research before they settled on the LP4. I have been in communication with their Tools Tech Team and they have agreed to do a test on my bracelets to see how well the LP4 will replicate my marking, how permanent it is and how long it takes. They have been really great to work with to the extent that they recovered my package from a different Post Office where it was stuck as a result of my using the wrong zip code on the label. They plan to do the test soon and then send the package back to me. I will report the results, but regardless of how well the LP4 does, I can already report that the Stuller Tool Tech Team has been really great to work with. I will pay a bit more for the LP4 if I buy it from them, but the promise of after sale help makes it worth the extra that I might pay for the LP4 package if I buy it from them…Rob

Following should be a picture of the marking test done using the LP4. Marks look good, now we need to see how permanent they are. Stay tuned…Rob

Hi, I am new here and came across this post. I know you are interested in just the basics for marking. I will say that the ability to do this has made my life easier.

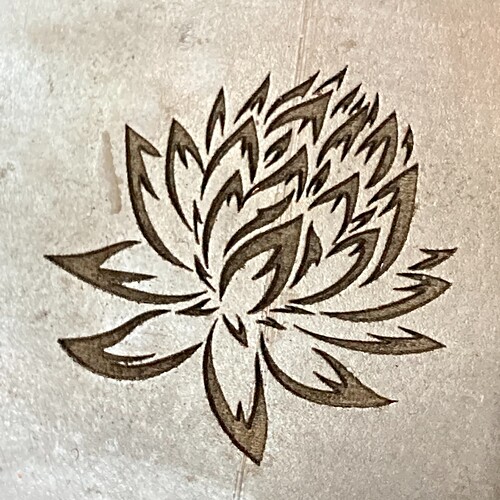

I recently purchased the ComMarker B4 30W, 110V with a D69 Rotary, and a fume extractor for $2690 with free shipping. It is able to lightly engrave like you see in the bottom wire on the LP4 photo you shared. It can also provide a pretty deep engrave on my Argentium rings. I just started experimenting deep engraving mild steel for texture plates (see photo of Lotus). It seems to do a pretty decent job compared to what you would ever get from paper.

I did a lot of research before purchasing this laser. Not many laser companies show you what it can do on precious metals or paper. I was originally interested in making textures with paper as well as marking. I did learn that you have to have an air assist in order to laser paper or it catches on fire. Most machines don’t come with great instructions. I use LaserEngraveEverything on YouTube as a great resource for settings. I find that most Facebook groups for each machine as a US based person that helps answer questions too.

I’m still learning how to use the engraver. I haven’t even touched the rotary. I mostly mark my rings flat. Sometimes I have forgotten that step and the ring has been formed. I just use a pair of tweezers to hold the ring. I then stack my test copper sheets halfway under the tweezer handle to tilt the top of the ring out of the laser beam.

Anyway, I know what I have is more powerful than what your are looking for but reach out if I can help answer any questions. I use Sterling Silver, Argentium, and 14k Gold Fill with brass core. I don’t use solid gold so I can’t really help with any questions in regards there. ~Kim