I am looking for a machine that can cut sheets of metal (14k gold, sterling silver, and gold filled) into small shapes and intricate designs. I am completely new to this type of technology, so I’m not exactly sure what it is I’m looking for or the correct terminology to use. Possibly a laser cutting machine? Does anyone have something along these lines that they have used to cut out their own designs from sheet metal, that they can recommend? Thank you so much for your advice and help in pointing me in the right direction!

Hi,

great query! i cannot wait to hear comments!

so, you would use computer generated designs…?

on a related note, another option would be a hydraulic press…and pancake dies, silhouette dies etc plus much much, much more…

julie

I met some folks in Vancouver who use a Trotec Fiber laser for cutting shapes out of precious metal sheet.

Like Julie said. Start with a saw and learn to cut your own. When you have some shapes that you want to duplicate, learn to cut pancake dies from 16 gauge soft steel plate and, using a hydraulic press, cut them out. Google Dar Shelton and Kevin Potter for a lot of information on pancake dies. If you want a lot of them, take a look at Kevin Potter’s FSS die system. I just bought one and they work great. He is limited to the shapes he can offer, but that could change. I am fairly sure that there are people who will make stamping dies for you and do the stamping. There are some small numerically controlled lasers that you can buy, but I am not sure how thick a piece of metal they will cut. Good luck…Rob

While I do not disagree with the value of learning to use the saw and any other manual technique.

New technology and techniques will open new opportunities and alleys of approach.

Each have their pros and cons.

So I can not see anything wrong with using a laser cutter for intricate shapes, if you have access to it and can afford the price premium.

You will probably need manual techniques to smoothen the cutting face and finalize the shape any way.

I see new technologies as opportunities to embrace not something to fear.

Regards Per-Ove

I am only suggesting that the same hands that guide the saw may eventually guide the computer and attached equipment that will render the final product. Wouldn’t it make sense to combine both sensitivities towards a better product? I have guided a saw and other hand tools for nearly 50 years making artful silver objects. I have also managed the design, building and application of digital academic networks toward solving problems for 20 years. It is from this point of view that I see creativity in first a hands on and, eventually, a digital approach to making jewelry. I am only proposing that we combine them both towards a better final product. My two cents…Rob

With that explanation, I totally agree.

The way I read it in your initial post I decoded it completely different.

There is maybe a language dimension to it.

I interpreted it as a completely write off of new technologies.

Sorry about that.

Regards Per-Ove

hi,

what is the price range for laser cutters? so fascinating!

i designed and had fabricated a stainless steel 2pc hinged heat shield for my soldering area…went to a local fabricator…they had amazing equipment…huge laser cutters, etc…i would love to kearn hiw to weld some day! …soon!

on a related mote, another great source for hydraulic presses, pancake dies, impression dies, silhoulette dies, etc is sandra sirles.

julie

Julie…You find the coolest stuff. Do you know where this business is located? Thanks…Rob

Hi Rob,

i do not know where they are located (good question!)

but they have an email listed in their contact section:

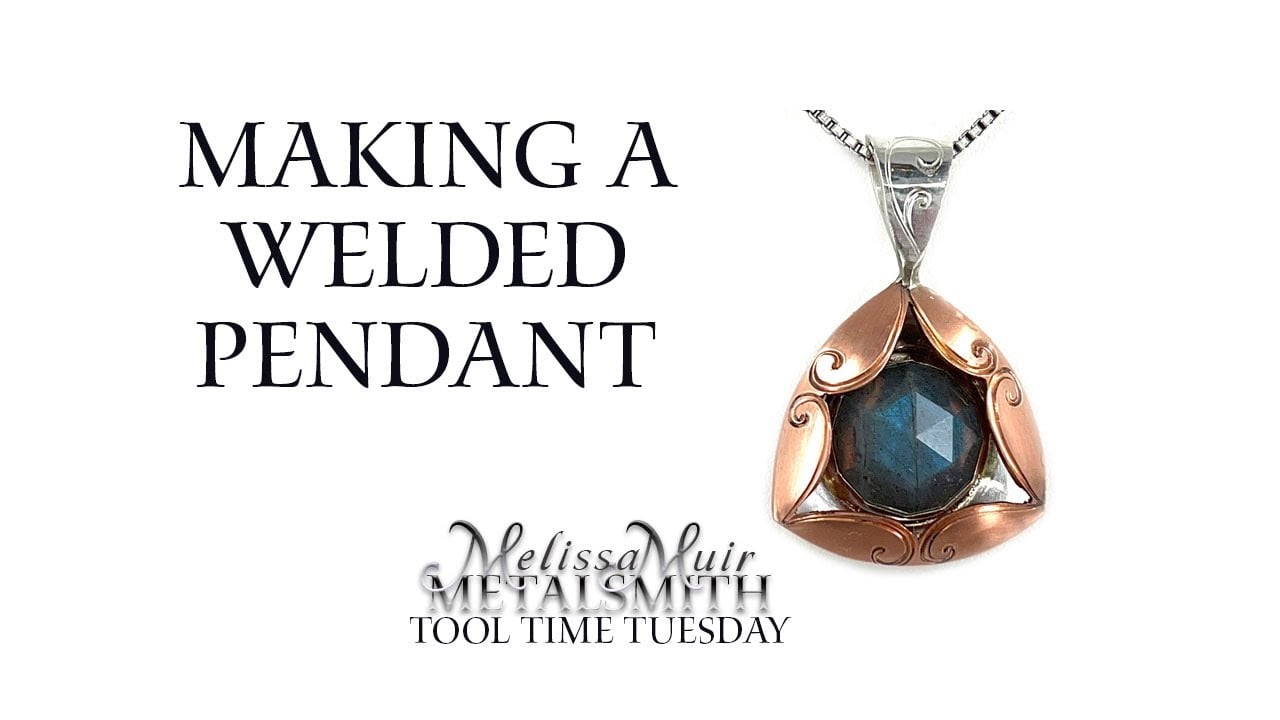

i first heard of them on Melissa Muir’s youtube channel

and! look what i just saw on her site today! (she was making a handpiece holder!) some nice yet inexpensive woodworking saws! (until (if ever!) i get a bandsaw!)

these saws were originally made in AriZONA…!

(approx-$9-13…!)

https://www.zonatool.net/cat/zona-razor-saws-razor-saw/

when i am in a funk and need to feel productive i play with wood! I usually make things for my tools!

julie

Hi,

and on a not so related note, on a welding video, Melissa Muir used a fret eraser (used on frets by guitar makers) (as well as a fiberglass brush to remove the oxidation from the laser, on a previously textured copper piece…

look at the grits on these i found…

i found it intriguing because my brother just sent me some special erasers he hunted down (he uses them to clean metal contacts on computer components) that he thought i might find useful…who knew?…erasers!

julie

Thanks for the input everyone! To clarify based on some comments and questions in the responses, I am looking for a computerized machine. I have a healthy budget and need something that can cut out at least dozens of shapes, if not more, in a day. I run a jewelry studio with multiple employees and we do not have the time to hand cut out each shape based on the style and volume of jewelry we produce in a day. Bonus points if it is bench top style (versus a large floor machine).

Another side note: I would also like to be able to cut shapes from 20G sheet. So many of the laser machines I have been sent to cut a max of .5mm thickness, or don’t work on untreated metals.

hi

here is an interesting site on laser cutters snd terminology

julie

What a great article. I have a hobby laser cutting and engraving machine and have heard of the fiber laser cutters but had no idea they could cut through metal like that. I was going to say look into a water jet cutter which uses a combo of water and grit material. However that might only be for thick metals and it comes in contact with the material.

learn how to use a saw first. its a basic needed skill for any metal worker imho.

I am familiar with how to use a jewelers saw, but that is not an effective technique for what I am trying to accomplish. I need a computerized machine to batch cut multiple pieces at a time to increase efficiency in the studio. Thanks for your input though.

If the shapes are simply to be cut from flat sheet you’re probably best stamping them. With a drop press or fly press you could die-cut hundreds an hour.

The computerized method will excel at small series, like say 5-25 pieces or slight difference in the pieces.

It will take more time than stamping but are way more flexible.

Last I heard sterling or fine silver can’t be laser cut.