I am making a gold ring for a customer and have a slight dilemma in that I am unsure how thick the metal should be for a 14ct gold bezel to fit a 7mm round topaz. I do not want to use extra gold when its not necessary. The shank will be about 5mm wide near the setting and tapering down to 3mm at the bottom.

I generally make gold bezels using 0.3 - 0.4mm sheet with a silver inner lining using 0.5 - 0.7mm sheet depending on the gemstone size.

I have found lots of information about making bezels, but little information about the thickness of metal used. Also cutting a bearing by removing 50% of whatever the thickness of the metal is, but my main question is: - Is there a formula or ratio about the size of a faceted stone to how thick a bezel should be in relationship to the metal being used. I am guessing that the ring shank also has an effect on this as well.

A general guide line would be a great use.

Thanks.

For a ring I’d make it at least 1mm thick and set with a hammer and setting punch. When setting stones in bezels I hammer the bezel 80% of the way down. Then I use a lubricated highly polished and very sharp flat graver and bright cut the inside edge of the bezel. Only after that do I hammerer the bezel the rest of the way down.

Have fun and make lots of jewelry.

-Jo Haemer

www.timothywgreen.com

Jo … bright cutting inside of bezel sounds like a slick trick … I’ll have to try that. Thanks!

Thanks Jo. You are always generous with your knowledge, which is much appreciated.

Great tip about hammering the bezel down about 80% and then bright cutting. Often when I bright cut after the bezel is all the way down I get metal ‘flanges’. This will avoid that problem. Great!

Would you use 1mm thick bezel for a larger stone, say a 11mm stone?

Thanks. Mieke

It depends on the stone, metal, and mounting. If it’s in a ring that would

be worn daily I’d go 1.25mm for an 11 mm stone.

-Jo

Dear me, I think I have been over ‘engineering’ my bezels. Thanks for your help, Jo, I will rethink what I am doing.

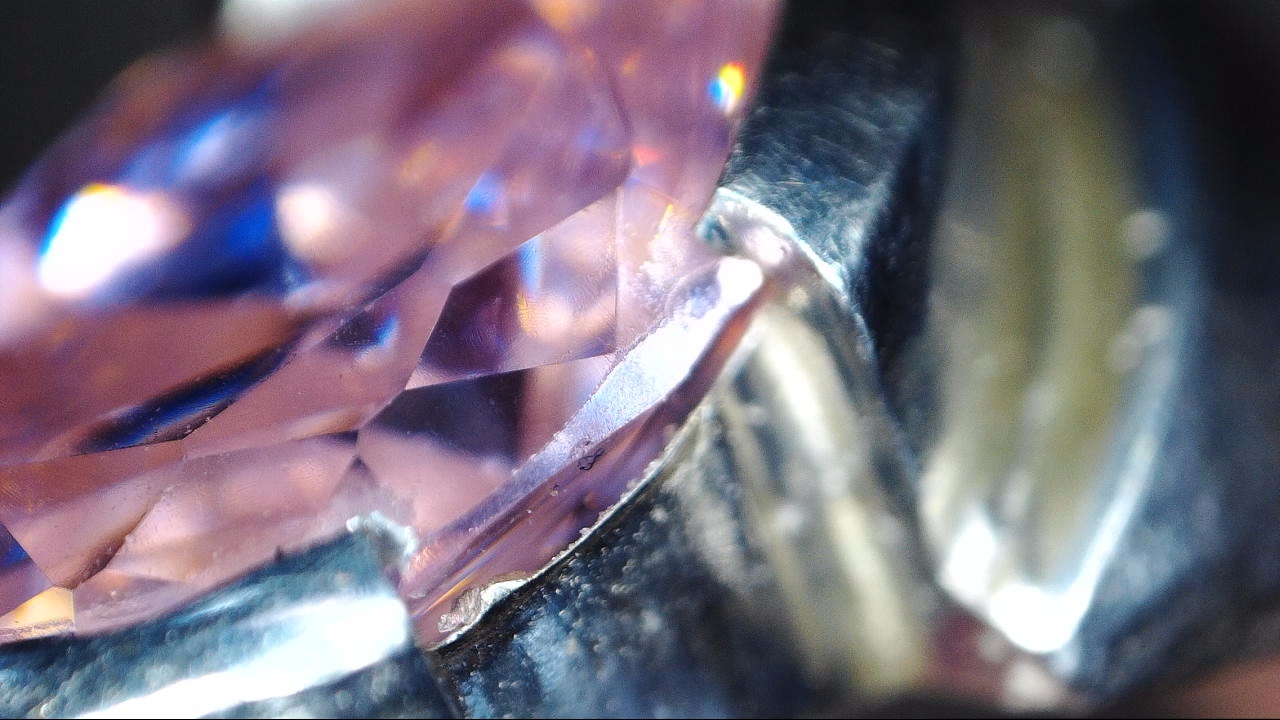

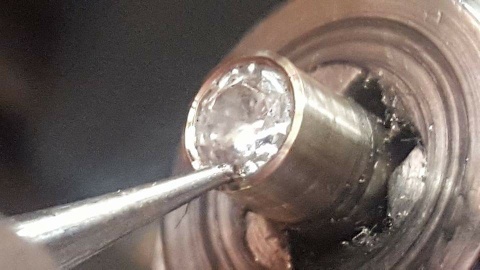

Enclosed you will view a simple Oval, Bezel frame…but in a 220x power magnification. Such a simple operation as setting a stone, can be made to look like a gargantuan setting ordeal. This one stone was simply a 9x7mm Oval CZ

I like Jo’s post about nice thick bezels. I have a list of adages that I hand out as part of the workshops that I teach. One is:

There are two lives inherent in a piece of jewelry: the life of the making and the life of the made. I always try to provide for both. In this case the durability of something as prone to wear as a bezel…

Please excuse any typos-- curse my clumsy digits…

I have learnt a lot from your videos Gerry, thank you for sharing.

Is a 1mm thick bezel considered thick? After cutting down 50% to set the stone, this leaves 0.5mm to push over and a 0.5mm seat for the stone to sit on. Is this correct?

I assumed we were talking about finished wall thickness…

Errrr… I think so. What I mean is, if the entire bezel from top to bottom is 1mm thick then you create a seat for the stone by cutting away 50% then you have 0.5mm to left to push over the stone, which thinking about it is actually quite thick isn’t it?

I still have lots to learn

Pre-formed fine silver bezel strip that’s available in the U.K. (From Cookson etc) seems always to be 0.3mm thick. And of course being fine rather than sterling silver it’s soft. Hope that helps.

Is this bezel strip primarily used for cabochons? I am setting a 7mm round faceted topaz. I probably didn’t explain this in my first message. Oops!

You can use the bezel strip for either cabs or faceted stones. For the latter you’ll need a step for the stone to sit on. Look up Soham Harrison ‘step bezel for faceted stone’ on YouTube. His videos are a goldmine! No doubt there are similar resources on the Ganoksin site.

Just to add to the bezel discussion.

I’ve made about 100 rings now, This is how it played out for me. I began mostly with 24 ga ( .5 mm ) thick bezels soldered to a flat backing plate, occasionally I used 22 ga when i felt it added to the design. The backing also functioned by providing the seat.

After awhile bezels were filed to fit the ring shank and soldered directly on, again with 24 ga and I used the shank itself as the backing, making sure to to keep the stone level as I set it. With the comparatively small number of rings I made, I never had a problem with a stone shifting or coming loose, but admittedly, my way of doing things needed improvement.

About 2 to 3 years ago, Richard Hopkins emailed me information on a better way. He showed that a press fit seat could be made out of 20 ga round wire and soldered in place. Since then using 24 ga, with both cabs and faceted stones, this is where I am at the moment, 24 gage on the outside, with a 20 gage seat.

In reading this thread, i am starting to wonder if it would serve me well to use 1 mm and learn to cut a seat with a burr ?

This is my personal progress so far, thinking that it might be helpful to some also new at doing this, thought I would share it.

Comments are much appreciated.

Thanks,

Mike

Ever thought of using tube to set round faceted stones? Choose the right internal diameter and wall thickness and use a burr to cut a seat and leave an appropriate thickness of bezel to rub over.

If I have a series of bezel to set I prefer to use the Fordom, Jacobs chuck handpiece, held in my BenchMate ring clamp bracket, as a lathe. I can hold the tubing in this lathe as I cut the seat, set the round stone, prepolish, and cut completed bezel setting off.

This makes the task of setting a series of identical round bezel extremely simple, and quick.

I do use tubing for small (4mm and less) stones but for larger stones it is difficult for me to source the appropriate tubing. I see that Cooksons only supply 9 and 18ct up to 6mm and for this project I need 10ct. There is always a small clitch somewhere  In addition, in this case I am making a tapered bezel.

In addition, in this case I am making a tapered bezel.

Thanks for the idea anyway.

Hi Mike, Can you elaborate on a ‘press fit seat’?

Cheers

Mieke