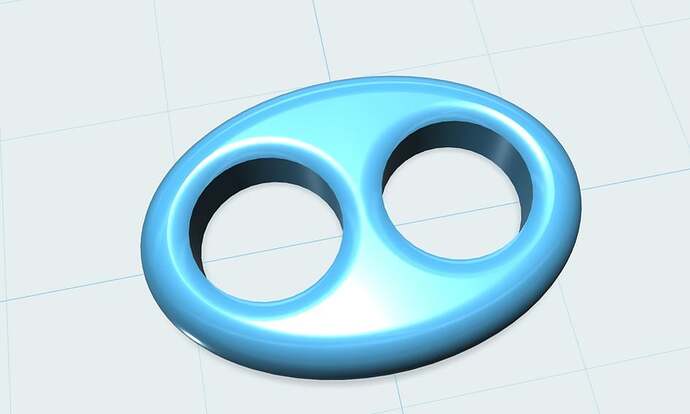

After watching a few tutorials and about 30 minutes of playing

around with the free Autodesk 123d program I created the anchor chain

link that I’ve been wanting to make so I can work on a personal

project of mine. This program is amazing, I’ve never worked with CAD

programs at all before I made this in less than 40 minutes including

watching tutorials!

I’d be happy to share the .stl (3d model file) with anyone. You can

just send the file to a 3d wax printer.

For simple designs such as this one, we should create a data base

where we can share design models that can’t be found anywhere else.

Thank you to Charlie of Seawear.com for giving me advice on this

project.

So many class acts on this forum, Charlie is definitely one of them.

Forty minutes?

You must be under 30 and have an attention span!

J

Charlie

After watching a few tutorials and about 30 minutes of playing

around with the free Autodesk 123d program I created the anchor

chain link that I've been wanting to make so I can work on a

personal

It’s a good start. I’d be interested in seeing the final printed

piece. 3d extrusions systems (that I’ve used or seen) won’t get near

that smooth of a finish. High end laser hardened resin systems can

come close but are more expensive. The.2 mm PLA printers are a middle

ground but their output is biodegradable so not necessarily jewelry

(or anchor chain) suitable.

You also note your project is “personal” but you don’t note “and

therefore allowed under the free license” but NOT if you intend to

use the Autodesk 123 for profit. Many of the “free” ones by the big

players (even Google’s entry) have that same restriction in their

license agreements.

And, of course, actually printing a chain with joined as printed

links will work reasonably well with the laser hardened resin with

filler systems (filler upping the system cost still more) but will be

(as far as I know) impossible to get reasonable smoothness and

quality on with extrusion systems due to the many overhangs and gaps.

Creating the 3d. stl is easy, creating the 3d. stl so that it

actually can be successfully printed is more difficult. Post a

picture of the printout when you’ve got it in hand.

James E. White

That’s cool that you can do that. I’ll have to check it out. I use

Matrix and make alot of custom jewelery. I’m going to look at this

program for home use. What’s nice is having a library of components

that you can use I. e. bezels or crowns, that you can use without

having to remake them.

Matrix has some but they are relatively easy to make in the program.

Scroll cutters are one thing I’ve saved in a parts file. Time

consuming to get just right, don’t want to waste time reinventing the

wheel every time.

Yes, I am young so that’s probably helpful for learning how to use

the program so quickly.

James White, appreciate your concern about commercial use of

Autodesk 123D but actually one can use it to create something and

sell it if they want to. It works like this. If you have the free

account, anything you create is shared and published in their data

base to encourage others to pay for 3d printing. You can still use

your item for selling as spelled out in their rules. Yes, when I said

"personal project", I really meant it. As in I am wanting to create a

anchor chain for myself out of Argentium. Everything I make on there

will only be printed through Shapeways which I think has a

relationship with Autodesk. But if you upgrade to premium account,

then everything you create is not published and is yours alone.

Here is the wording: "Any 3D model that you create with our 123D

applications and share to our 123D Gallery CAN be used for

commercial purposes, regardless of whether you upgrade to our 123D

Premium membership.

The reason is that we want to encourage and reward users who share

their work with the larger 123D community."

This is the most brilliant idea I’ve ever heard of when it comes to

commercial VS non commercial use of a product. It encourages more

people to print 3d items and in they end they make more money and no

one is bothering to sue each other. I guess lawyers will hate this

idea.

But like you said, the quality of the printed design may be better

if you purchase a more serious program like Blender or Maya to create

3d models.

So very serious jewelers would be encouraged to purchase software

like that because when they print those items they will need less

cleanup perhaps after printing in the high resolution resin.

But for small time guys like me, it’s simpler to just use any 3d

modeler, then use Shapeways to print the item in polished bronze for

a metal master for only 20 dollars… then do any final

sanding/polishing before making a mold.

Got it. Still not a bad thing for others to be able to use your

designs I guess. You think you’ve come up with something original

then find that they did it pure something similar 200 years ago

without the fancy equipment. Not much out there is different than

anything that’s been done before. Keep it up, have fun

I LOVE this software. I used it at work to make a 3D model of an ear,

which I could then modify any way i want and print using a 3D

printer. It works surprisingly well, and could definitely be used to

get a 3D model of a small object for jewelry design purposes. Usual

caveats apply about recessed areas, shiny objects, etc. Not perfect,

but hard to beat for free. I did try several alternatives and found

this one, the best.

James,

I have a extrusion printer that I built from a kit. it’s default

resolution is.1 mm people have tweeked theirs to be.02 mm (I have

not gotten that far yet.)

For that matter, mine needs a lot of tuning to be a quality .1 mm,

but I will get it there. I am not printing jewelry with mine

however, but I am making tools and jigs to make my jewelry.

Cheers!