The easiest and cheapest way to buy oxygen is get it from your local welding store. Linde’s retail outlet where I live has gotten very picky about bottle ownership. They want to rent you a bottle so they can charge you whether you use it or not… insist on buying one and getting all the paperwork and keep it. I bought a 100 cubic foot bottle years ago and have exchanged it multiple times over the years for a full one. With exchanges, you just pay the price of the oxygen. I also have an acetylene bottle. It too is exchangeable when empty. I also have a light duty MIG-argon welder. Both were purchased initially to do auto body repair, and then later to repair steel lawn furniture and make heavy duty wind resistant windchimes and mobiles. The gas set up I have includes a carrying cart with wheels and a safety chain to hold the bottles in place. It’s heavy but transportable. I always use oxyacetylene outdoors only. you have to start the acetylene first, which creates a lot off wispy soot, before turning on the oxygen and adjusting the gas flow. Having any oxygen on while lighting will cause a pop and potential blowback. When turning it off, the oxygen must be shut off first also, creating soot. Otherwise there will be a loud pop when the flame goes out, again with potential blow back. I have both cutting and welding tips, but only use the cutting head with multiple orifices to melt. Using MIG to weld is far easier than using gas to weld.

Acetylene is DANGEROUS!.. To my knowledge, acetylene is NOT compressed to a high pressure, which could make it spontaneously explosive, even in the absence of oxygen or air. The bottles are partially filled with a sponge like material and solvent, in which the acetylene is dissolved in. It has to be handled with care. The bottles should never be dropped or let to fall on hard surfaces. There is a very small risk of percussion detonation. Never keep compressed gases sitting exposed to the hot summer sun, and don’t store them inside of your house. The same applies to 20lb propane bottles. I keep mine in a cool detached garage, away from the house and wheel the set up to where I use it outside…If overheated, the bottles do have an overpressure relief valve, but overheated acetylene also has a small chance of spontaneous detonation…Acetylene chemically, is two carbon atoms joined by a triple bond, with one hydrogen atom attached to each carbon. The triple bond between the two carbon atoms store a lot of energy but also makes it unstable. When burned, the bonds snap apart, releasing bond energy, in addition to the combustion energy of the carbon and hydrogen atoms. That chemistry allows it to burn at the highest temperature of commercially available gasses. The instability of the triple bond is what makes acetylene explosive. The molecule wants to snap apart due to bond strain. Propane and oxygen burns at 4,800 degrees F, while acetylene burns at 5,500 to 6,000 degrees F. Propane contains three carbon atoms and 8 hydrogen atoms. It has a higher heat content per molecule than acetylene does, but it requires twice as much oxygen to burn propane than it does acetylene. That being said however, is that the trade off is that the price of all compressed gases have gone thru the roof. The price of acetylene has skyrocketed, while propane and compressed oxygen haven’t gone up that much in comparison, but still expensive. If only used for melting and preheating an ingot mold, you won’t use up a lot of gas. If used for soldering with a small torch set up, you have to be careful because overheating can happen very quickly. Air acetylene burns at over 4,000 degrees and overheating can happen quickly, but oxygen and propane burn at even a higher temperature. Since acetylene has become expensive, compared to oxygen, there’s no advantage of using air/acetylene. I haven’t used oxygen for soldering since that high of a temperature isn’t needed. For melting and pouring, high temperatures make things easier… the metal can be superheated for a clean pour and melting goes much faster. This can be done with air/propane if a high output torch head is available, but there’s not one for bernzomatic disposable bottles…It’s not only the combustion temperature that counts but also the total heat energy output per second th at counts even more…the higher the heat output, the more gas is burned faster…I’ve found that a regular bernzomatic propane air hand torch does not have enough heat output to do the job well at all. I have never bothered to buy a little torch propane or acetylene air setup since I already have an auto shop sized oxyacetylene setup…The heat output is very high which makes melting quick and easy… A little torch set up will take longer to melt and preheat an ingot mold as the total heat output will be much lower.

I also have a question about pulse arc welding. Light duty MIG welders have a continuous output of up to 100 amps at 24 volts. That’s 2,400 watts continuous. I’ve looked at the technical specs for pulse arc jewelry welders but haven’t been able to find the pulse duration, nor the amperage of the pulse, nor the strike voltage. The pulse output is rated in joules, which is watt-secs. watt-seconds or joules is the total amount of energy applied. The power is energy per second. The pulses are capacitor discharges and must have a very short duration, milliseconds to achieve very high power. I can’t calculate the power without knowing the duration of the pulse, nor can the power be calculated without knowing the amperage and strike voltage. Does anyone know where these technical specs can be found?..

Electric arcs have temperatures of 10 to 12,000 degrees. The arc temperature is far less voltage dependent than amperage dependent… Continuous arcs put out dangerous amounts of ultraviolet radiation due to the high temperature. Using them requires a welding helmet and protective outer garments to avoid getting badly sunburned (I learned the hard way early on). Short duration pulse arcs will also achieve the same temperature, but put out much less UV, due to the very short pulse duration. Still eye protection in the form of welding glass shields are necessary, not only for protection against UV, but also to see what you’re doing since the flash is so bright… doing a spot weld with eyes closed does not work well, as you won’t see exactly what you’re hitting. Even though the maximum total energy deposited by a single pulse is only 30 joules or 30 watt-seconds (the equivalent of about the weight of 30.5 grams dropped a meter) the pulse duration has to be very short to achieve sufficient power output to melt metal… with the amperage being very high.

I did read once about a DYI project making a spot welder using a sharpened carbon electrode, a foot switch with a rheostat to control the current, and a 12 volt car battery as a power source, as car batteries put out a huge current… up to 500 amps maximum on the best batteries. I never bothered to experiment since car batteries at that time were heavy, cumbersome and weren’t sealed to prevent acid spills…I also didn’t think that it would be controllable enough except to use on sheet steel metal.

I have an air acetylene torch also for jewelry purposes that I can hook up to my big autoshop acetylene tank. I completely agree with you that they work very well, achieve high temperatures quickly and make metal working fast… I’ve used it several times but went back to propane/air because that was cheaper and sufficient to do fabrication work. For melting and pouring ingots, my regular cutting torch with multiple orifices has a very high heat output… it’s oxyacetylene… an added bonus is that the center orifice injects only oxygen. It’s the oxygen that burns thru steel to cut it. By injecting oxygen into molten mixed copper/zinc/silver scrap, the oxygen will burn off the zinc first, then the copper, leaving “spitting silver”…fine silver absorbs a large amount of oxygen without being oxidized itself… once the silver starts to cool, oxygen bubbles form and pop out. … that’s the point where it’s been “fire refined” to fine silver. I’ve had it assayed and it was close to fine. The major problem with doing this is it takes a lot of borax flux to absorb the oxidized copper and zinc. That creates a sticky mess. This HAS TO BE DONE OUTDOORS… I don’t melt or fire refine indoors…small droplets of spilt hot metals will burn thru a hardwood floor in seconds… I won’t keep a large acetylene bottle indoors.

Forgive me, but this is above what my feeble artist brain can answer! I really like the Orion owner’s manual as it’s filled with technical info. You can download it for free. The 200i3 is their model of welder with the most amount of potential adjustments. You can adjust the power output, the length of the pulse and the arc modulation. Try downloading the 200i3 owner’s manual and see if your answers are there. If not, feel free to reach out to Orion and ask them.

I don’t think the PUK system is as adjustable.

I do know is that both systems have super quick auto darkening systems to protect the user from the arc light.

Here’s a link to the 200i3 owners manual. Sorry that I’m not more help!

Jeff

Thank you so very much, my curiosity has been meet completely… The screen waveforms give me all I wanted to know…It’s a classic capacitor discharge with a defined time constant.(rate of decay of the voltage, or in this case, total energy, on the capacitor) The waveforms can be modified into a sawtooth or square wave pulse…The area under the curve is the total charge and energy released. The first example shows the energy being released, with 2/3’s of it being released within about 50 msecs… That’s a 1,900 watt pulse at displayed setting of 82 total joules, if I did the math correctly…quite enough energy to do a spot weld…

Sorry If I’m talking physics… but this is the kind of thing that I have to teach once in a while…I’m doing far less jewelry in my old age but am following the chemistry and physics more closely. I took a highschool course in jewelry making, working with silver, left it behind for advanced study and returned to it years ago, before the technology that’s here today was available. Pulse arc, laser, micro machining tools came all after my time. I’m glad it’s here because it makes the work go so much easier.

Steve

I was thinking that. Time to make an order at riogrande.com lol

So very glad that I could at least point you in the right direction!

Jeff

One thing that rarely gets mentioned is that you should not draw off too much acetylene. Meaning specifically, you should not use the Silversmith #4 torch tip with an MC tank.

Neil A

Hi Neil A,

Can you explain why? That info will be helpful for folks.

Also to confirm, you’re talking about a “MC” size acetylene tank, not a “B” tank right?

Thanks!!

Jeff

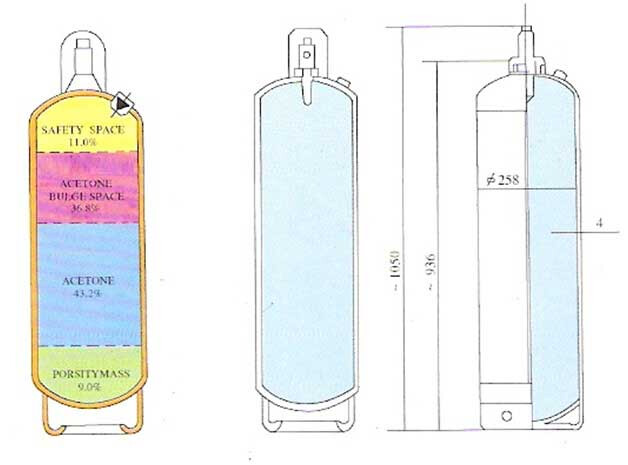

Acetylene is a very unstable gas when compressed, so it is not actually kept in gas form inside the tanks. It is dissolved in acetone suspended in a sponge like structure. If you empties it too fast I guess you can risk that acetone follows the gas and both the tank structure and the torch can be damaged and the tank may even risk going into decomposing mode and overheat.

This is the reason for the low pressure of about one tenth of the oxygen tank.

An Acetylene tank looks like this:

Im sticking to Propane and oxygen. Haha

Yes, acetone is the solvent… the bottles have to be kept upright at all times. IF laid on the side, you need to wait for 30 minutes for the acetylene to re equilibrate with to solvent, otherwise your torch will become a flamethrower with the liquid acetone acetylene mixture being thrown out… The regulator main stage should not be set above 15 psi… acetylene gas unstabilized in acetone will become spontaneous explosive and could detonate in the hose. That’s why acetylene is dangerous!!! and MUST be HANDLED with CARE…

Yup, it’s complicated but was able to calculate my answer to my question… the pulse is very strong and very short…less than a 1 tenth of a second, with most of it in 2/3’s of a tenth of a second… 1,900 watts if it were a continuous power source and not a pulsed one…light duty MIG wire fed welders put out a max of 2,400 watts…Thanks again…

I think im going to get this to melt…

Check this out! https://a.co/d/fROIMUe

This thread has taken a number of twists and turns from the original question related to the Little Torch rosebud tip. But since we’re here and beginners are reading this, I think it’s clear that both propane and acetylene have pros and cons.

Folks have given a fantastic explanation of why acetylene tanks/torches need to be treated with respect and the need to follow all safety protocols. (like always keeping the tank upright and not allowing the working pressure to ever go over 15 psi). It’s also important to remember though, that acetylene has been used safely in jewelry making for decades.

It’s also important to remember that propane tanks have many restrictions as well and are also potentially dangerous.

Flammable gas torches need to be treated with respect and to follow all safety guidelines.

When deciding which gas to choose, folks have to balance out all the factors and make the best educated decision for themselves of what to use in their studios.

I’m mentioned this often, but part of the choice of what fuel to pick for your jeweler’s torch really depends what your situation is. It also depends on what your state, county, city and insurance company will approve.

It sounds like a lot of us, myself included, have taken the path of having the smaller tanks, meaning less gas, rather than bigger tanks and more gas in their studios.

Also to answer the original question, a number of us, like myself, don’t have any problems using the Smith Little Torch Rosebud tip with a 16 oz, campstove propane tank and a full size oxygen tank.

I hope that helps!

Jeff

Thanks jeff. Looks like i need to get the full size tank.

well put. thanks to everyone who contributed. steve

induction or resistance heater? I’ve read that there are several induction ones that can melt platinum also but require 240V input…

PS: …I need to add that not only has it gone very well but all gases are safe to use if used properly. Knowing the potential dangers of not using them properly is good to know also. Ultimately it’s a personal choice of what you want to use as gas, taking account cost, and what kind and how much work you do. A commercial operation is vastly different from being a hobbyist. I’ve been only a hobbyist, but also have experimented with different techniques and gases. Each kind of setup can be customized to one’s needs. Arc, laser welders, torches and fuels will depend on what you want to do, how much you do and your personal choices that meet your needs… again thanks to Jeff… and thanks to all who have contributed… I have learned a lot from this discussion. Don’t have anything more to add.

Great visual and written explanation. So may metals artists are visual. When I was in metals in college I used to tell my more academic friends that in the art dept. we don’t read as much as they do. We just look at the pictures. And the same for writing papers. We just present what we made.