I made a magnetic clasp for a loop in loop bracelet. It consists of one smaller tube whtich fits into a larger tube. I glued a 3mm x 2mm disc neodymium magnet in the male side and a 5mm x 1mm disc neodymium magnet in the female side. I used blue cap gorilla glue. The client called me after only one day and said the magnet in the male side came out. The glue didn’t hold. What epoxy or glue would be best to hold the magnets?

Most cyanoacrylate glues are not good at filling gaps. The pieces need to be in intimate contact throughout for the hold to be good. There are cyanoacrylates that are thickened to help in fixing imperfectly fitted joints, but most super glues aren’t thickened.

My preferred epoxy is Epoxy 330. It is water-clear, and doesn’t yellow significantly over time. It is thin enough to be drawn into a crack when initially mixed, but will fill thin gaps between the parts.

The nickel plating of neodymium magnets does not give any glue much purchase. You should slightly roughen up the side to be glued on a piece of emery paper to give it a bit of tooth. This will help the epoxy bind to the magnet.

There are several glues I would try. First is from wood working stores. They have three grades of super glue/ cyanoacrylate. It comes in thin, medium, and thick. I would go with the thick. It is designed to seep in deeper and take longer to set up. It should be ready to go in about 10minutes. The next would be from a store that supplies gold club making equipment. They have a epoxy that holds the heads of golf clubs on. Check with them and ask which one is the one to hold up to 10K pounds of pressure. This is a two part epoxy.

I have had good luck with Starbond glues…Rob

Im not surprised it fell apart,

you should have run a trial FIRST before trusting just any odd glue

also dont use a cyanocrilate, ie super glue. No the right stuff for your

job…

Run a trial and report back here with the results.

I think youll find that almost any 2 part epoxy glue will be strong enough,

for your problem, is the lack of a proper preparation of the 2 surfaces.

Use your dremel with one of those sintered cut off discs to roughen

up the magnets,

as well as the metal.

ted.

Metalsmiths wrote:

In my experience with magnetic closures, glue isn’t enough. Make some kind of mechanical holder for the magnet in addition to glue. Pressing a magnet into a setting is what I do.

Judy H

I have a set of hydraulic press bracelet formers from Potter USA. They are held in place with a small magnet in the bridge. There is a prick punch mark on two sides of the magnet where it meets the metal around it. They really take a beating when I use them and none of the magnets have fallen out. You can also take a look at:

They sell magnets with 3M adhesive already added to the magnet. Just some thoughts…Rob

I rely on 3M two part epoxies for gluing dissimilar surfaces. They have never failed me. Check out https://www.3m.com/3M/en_US/p/d/b40066487/

They need a special applicator gun and it may seem wasteful for such a small amount of glue, so try and do several glue ups at the same time. Crazy glue does not work well for magnets. Just too brittle.

This How to Bond Magnets article is on the site of a company that has been developing and manufacturing engineering adhesives for five decades.

Janet in Jerusalem

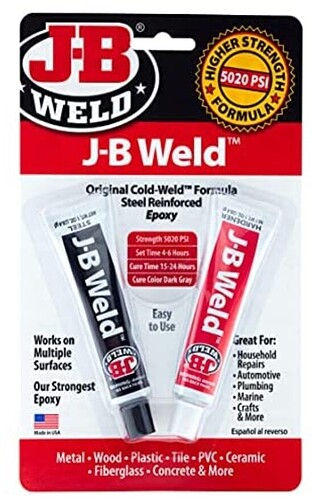

Like John I will try JB weld, I used to glue a ceramic magnet to steel on a motor spinning at 4K rpm. Lightly sand both surfaces with 320 or 600 grit.

Totally agree that I should have run a trial first. I glued them in and all seemed well. I tested it for a couple of days and it seemed fine. What I didnt do was test it in various environments. Im wondering if that is where my problem lies. The client wore the bracelet into the desert and also went swimming with it on. Need to study up on this more. Thank you for your advice.

No, the problem is not the various enviroments, its the Proper

Preperation to both the metal and magnet.

This is where you need to run trials.

Repeat what you did, then repeat with ther coarse abrasion needed for

the epoxy to kee to.

When you have done this let us all know, as this sort of info is of

importance to all folk here.

Ive some epoxy I used 50 yrs ago and its impossible to seperate the 2

items!!

So I ended up using JB Weld steel epoxy. I was a bit surprised that it wasnt clear but with careful application it didnt show so not being clear didnt matter. It worked like a charm. Thank you for everyone who gave me advice.

I concur with JudyH; lock it in with a mechanical setting of some sort. It is how I did mine in my bracelet. I didn’t even use glue. I think many glues breakdown over time. Good luck.