How often have YOU asked yourself that question?

In my newest essay #83, that question will now be discussed. I will answer that simple and yet interesting question showing you 5 different ring clamps & 20+ photographs.

I’m very sure once you read this informative essay, you’ll have a better understanding the ‘pro’s & con’s’ of each clamp. I’m answering ‘how each can be used & of course where’?

I put many “demo-rings” in them, you can see for yourselves just how they seem to answer your first question,"WHICH BASIC RING CLAMP TO USE?"

Regards to all and everywhere!

"Which ring clamp should you use is a reasonable question?" The clamp options are wide & varied including which to choose, when & why not?

I know that there are many types to pick from & I have 5 styles to choose & each with all a different purpose!

The following photographs will show you which to use, why & what are ‘good & not-so-good’.

Let’s start with the “Inside Holding Clamp” This mechanism is of two clamps that are my best, why? It doesn’t interfere with any designs (Azure patterns) to the inside of the ring.

The plastic insert expands and secures the ring from sliding sideways when I’m Hammering or Raising beads. In this photograph, I was applying a “Florentine” pattern to this ring!

Here I am getting up close and starting my " Gypsy/Flush " drilling of the bearing cut. I need to see and have close proximity to the ring, if not the stone, this clamp affords that opportunity.

I was confident that this ring won’t move while using my “High Speed Steel” bur. My other comment on this is that my 'hand & fingers" are really being close together around the clamp and not too far apart. The word is “comfortable”, this is so important in everything we, as setters must be.

Here being shown, are the many ring inserts for this “inside ring-holder”. There are newer clamps built on this idea, this was the first on the market 15 years ago and then many improvements have come our way. But I’ve done much in using this particular clamp and its served me well…:>)

The second one, of the well-used ring-holders that I use , BUT there is one drawback and it can be a darned nuisance to the setter. It’s that large tightening screw that is on one side of this great clamp.

Can you now see why I find the screw a great problem? I even filed half of it away when I bought it. So should you, if you choose to buy it.

I call this a “ring-vise” as it holds the ring from the outside and it is so important that no movement is allowed. You can see it, as it is holding the ring very securely that you won’t have any problems in having the ring rotate or have any sort of movement. (I even have a pair of pliers to tighten it further!)

I was attempting to set these delicate Triangular stones in this ring-clamp. But ‘security’ weighed over the screw getting in my way.

I kept the ring in this clamp and I worked around this problem by just rotating the screw to be ‘under’ the bench-pin… Problem solved!

Here is a side view and the name of this very interesting ‘screw-type’ clamp.

Can you tell me how many clamps are there that allow you to hold the ring in this position? But you are then limited ‘just by that extra piece of metal sticking up and interfering with your finger-tips’ and the bur you might be needing. Great idea, but this also has some limitations as you have very limited access to getting your burs near the stone.

I really like this metal clamp as it allows my fingers to get really close to the ring that’s being set.

Even with an additional layer of leather now joined to the inside the clamp, there isn’t any risk of damaging the tube. The tight grip by way of this vise, the tube isn’t going to move.

I didn’t want to have my fingers too far away from what I was doing. This style of clamp served its purpose…nicely!

Just another view of the tube-like setting. The tightening really helped in this case. No need to worry if the tube got loose while setting, it got tightened further with my pliers.

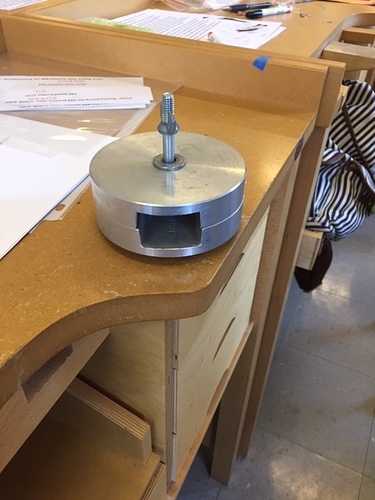

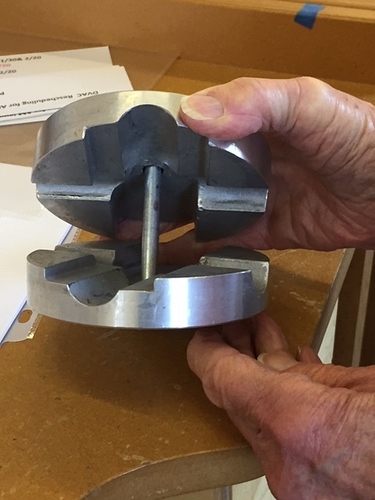

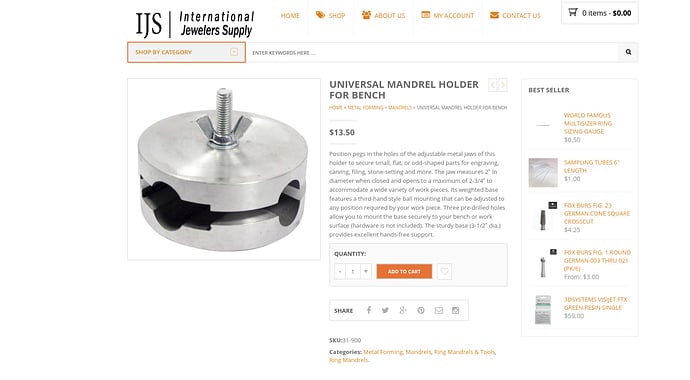

This style of clamp is not to be used at all for any sort of rings. It was meant for items that have a wide circumference, as in this replica made in silver “Guinness World Record, Poker Chip” , that is now being displayed on its side!

You can see the little pegs holding this very unusually wide item. BTW, for the record, the official “Guinness” certificate was given to me on May 30, 2013.

This is the best holding devise that I have, I can move it so easily and not be limited to any engraving-ball that is on the market with all tool suppliers.

The extension of the 'working surface’ can reach 67.38 mm’s or 2.65 inches in total. BTW, I didn’t have anything that wide to show you, but you get the idea, agree?..:>) Nice!

Here is the actual name engraved into the side of the other clamp , but it is locking by one simple holding pin. Those two sliding vice-grips on top are not thick enough to hold really anything.

I found that wanting to tighten anything, those sliding top-plates really cut into my setting projects. This left deep cuts into the metal & caused me many reasons to clean & fix…not nice!!..:>(

After many attempts to use this " Setters Hold It " clamp, I’m putting this clamp aside for Diamond Setting. There may be other few uses for this style of clamp, sorry but this setting tool is not for me! I might just donate it to school, or another student…:>(

I’ve been using a wooden clamp since the day I started Diamond Setting & that is only 56 years ago. I still find many uses for the wooden clamp, as I enjoy using the flat and wide surface on this clamp.

Here I’m Bright-Cutting the inside of an Oval Bezel, the clamp holds the ring steady & gives my fingers easy access to the ring instead of crowding of my finger-tips.

In this photograph, you can see that after so many years the leather has gotten worn away. This is quite ‘normal’ of continued use and had to use a new layer. I just used an old leather belt and kept the old one to give me more ring support.

I am showing the thinnest width of clamps and to the widest. It all depends on which you as a setter, can now select. Do you want crowding of your finger-tips or which clamp do you need to hold your item for a setting? YOU SHOULD SELECT THE CLAMP THAT YOU ARE ‘COMFORTABLE’ WITH.

The next problems you ‘might’ encounter are, when you are setting stones for a long time, perspiration on your palm starts to occur. That can easily be eliminated by using a wooden clamp as metal doesn’t allow the sweat to disappear.

You gotta have room for your finger-tips as well not to crowd each other. I’ve had that problem occur on many an occasion.

Have you made your decision on which clamp to buy and use? My suggestion is to buy the one that you will be quite comfortable with for years to come.