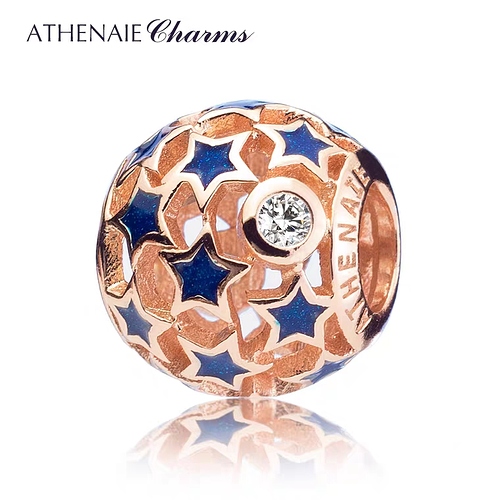

My first guess would be CAD to 3D print or wax carving and lost wax cast. Clean up with fine cutting burs, string polishers, etc.

Doing it by hand would be more challenging. You’d have to form the two halves of the bead and solder them together. Having the two halves would allow you to use a saw to do the cutouts, etc. before assembly.

If you could get a pre-fabricated hollow bead then using a saw would be difficult, so I’d probably use drills and burs to cut and shape the gaps between the stars.

Either way you would need a micro-vise block with the points attachment to put the bead between the two points to allow you to rotate it and work on it for the enamel or epoxy coloring.

Setting stones would require filling the interior of the bead with shellac or thermoplastic to allow you to work on it and help prevent it from collapsing, unless in these bezels you can push the metal down without a lot of pressure, maybe with an air hammer/engraver or something similar?

-Ron