How do I know what size blade to purchase? I will be cutting

jumprings out of different wire gauges. Do you need a different size

saw blade for each wire gauge?

Tamara Wright

How do I know what size blade to purchase? I will be cutting

jumprings out of different wire gauges. Do you need a different size

saw blade for each wire gauge?

Tamara Wright

Hi Tamara,

How do I know what size blade to purchase? I will be cutting jumprings out of different wire gauges. Do you need a different size saw blade for each wire gauge

The number of the saw blade being used really depends on the gauge

of the wire being cut. For cutting ease with a hand powered saw there

should be at least 2 teeth in contact with the metal at all times.

If you are making chain, rings will be above 20 ga most of the time.

This would call for a # 0 or smaller (2/0 - 8/0) blade. The #0 or

smaller blades can be used on larger gauges as well.

Another thing that helps when cutting a coil by hand is to keep the

coil secured to a solid surface. Placing the coil in about a 1/8"

wide slot cut in the center of the 1 1/2" dimension of a 1 1/2" x

3/4" x 3" piece of wood helps. Place the coil flush with 1 end of the

block of wood, then wrap apiece of masking tape around the coil & the

block for about 1". Holding the block close to the edge of a table or

bench, tip it up so the block is about 45 deg to the table/bench &

start cutting the top of the coil. When you find it hard to keep from

cutting the bottom of the coil, stop. Remove the masking tape, move

the coil down so it’s flush with the end & wrap with tape again.

Begin cutting as before. Repeat this procedure until all or enough of

the coil is cut.

Dave

Tamara -

After wrestling with the ‘right’ size blades for years (the ones

everyone said I should use), I found I work best with a 6/0 blade for

everything. I have done delicate tracery out of 28g sheet worked my

way through double-thickness of 20g sterling, and cut out a sturdy

design from 16g sheet, all with minimal blade breakage.

The ‘right’ blade will have at least 3 teeth in the metal at all

times. Problem is, I can’t drive the saw once I go to thicker

gauges. I try to start the cut and the blade jumps and skitters

across the edge of the metal. Maybe there’s something wrong with my

wrists or fingers, but I fight with blades bigger than 6/0.

I give classes in my shop, and one of them is all about the jewelers

saw. I have my students use the same blade and they love it (women &

men). Most of them have a smidge of experience with the saw and they

are gunshy. It’s due to the effect of the larger blades.

I’ve conducted a series of tests for myself where I cut a

double-thickness of 20g sheet using a #1, a 2/0, 6/0 and 8/0 blade.

I broke all the 8/0, fought withe the 2/0 and gave up on the #1.

I thread my blades quite tight, maybe that’s what helps me. I feel

like the blade slices through metal like butter, it can practically

turn in its own width, and I can cut as fast or faster with it than

I can using other sizes. Though I cut most of my jumprings with a

circular saw attachment to my #30 handpiece, when I want jumprings

RIGHT NOW I use the saw with no problem. Talk about a narrow kerf!

My experience (and my students’); YMMV.

best regards,

Kelley Dragon

Tamara, Please see the attached chart which is part of a class paper

I give to all my students. It applies to whatever you are sawing,

sheet or wire etc., and should answer your question. Cheers, Don.

REMEMBER: Sawing off a piece of metal saves precious metal for other

uses or to melt down and remake into plate or wire. Filing or sanding

the metal results in a pile of metal dust good only to a refiner

Metal

B&S Gauge Blade size Drill size for piercing

26 plus 8/0 80

24-26 7/0 80

24 6/0 79

22-24 5/0 78

22 4/0 or 3/0 77 or 76

20-22 2/0 75

18-22 1/0 73

20/22 0 72

18-20 1 71

16-18 2, 3, 4 70, 68, 67

16 5 65

14 6 58

12 7 or 8 57 or 55

Think of blade size as a cross ? with 0 at the center of the cross.

Single digit blades ( 0 through 8) are coarse cut and all above the

cross bar while -/0 digit blades (1/0 through 8/0) are fine cut and

all below the cross bar.

I would use 8/0 or 6/0 sawblades for this application. The reason is

the smaller teeth will cut easier and you will have less loss of

material. In selecting sawblades you always want more than one tooth

of blade for the thickness of the metal. Otherwise they will catch on

the metal sheet. For example, an 18 gauge sheet, 1mm thick, you could

use 4/0 the average blade size. You could use 2/0 as well. But if you

are on 30 gauge sheet you want more teeth in the blade so move to 6/0

or 8/0. It also depends on your application such as jump rings or

sheet scroll cutting, etc. If you have a lot of breakage in the

blades it is either too tight or too loose in the saw frame.

Good Luck,

Russ Hyder

Hi Tamara,

Contenti has some great charts, including a Saw Blade & Drill Size

Chart. Check out the Resources link…

http://www.contenti.com/resources/index.html

Pam Farren

Newburyport, MA

I am a lot more familiar with circular blades but in general my

company uses blade with a 1.75" diameter, 160 teeth and thickness

0.008 for wire 0.032" and smaller and 0.010" for larger wire.

We use these blades in connection with some fancy computer

controlled jump ring making equipment but with a bit more work you

get the same effect with any motor powered saw cutting set up.

For the classic hand jewellers saw the rule of thumb is you should

have a min of 2 teeth per wire diameter and you buy blades by teeth

per inch and the thickness of the blade just works itself out. I

likely have a list of what blade numbers go with what wire gauge

someone if anyone is interested. I tried cutting jumprings using the

handsaw just for the experience and came to the conclusion it was not

exactly a cost effective way to make a jumprings ![]()

Jon Daniels

The Ring Lord Chainmail

Jon, if I were making and selling jumprings on the scale you do

(thanks) I wouldn’t find it a very cost effective way to make

jumprings either. But before I got my Koil Kutter, when I was in the

middle of a design and realized I didn’t have enough rings to

finish, saw cutting made an efficient if not easy way to cut those

extra rings I needed. Of course now I have a Koil Kutter so I can

eliminate the hand saw… At least for jump rings. ![]()

Michele

MikiCat Designs

Speaking of sawing, Thanks for the tip. I love sawing intricate

patterns, and have always felt intuitively that I was fighting with

the 4/0 blade. It always felt gigantic, but I am relatively new to

jewelry making, so I thought It might be inexperience. I can’t wait

to try the 8/0. I make alot of earrings and rarely use any metal over

22- 20 gauge so I think it will work. I’d like to hear from those who

have tried intricate pattern with the Knew handheld saw, not the big

one or the electronic one. Also what are the best blades,any

opinions? One little segue, on the topic.

I have heard through friends who took a course with Chris Darway of a

wonderful new tool that is more portable, than a drill, for piercing

holes? They could not remember what it was, but believed it was made

in Rhodes Island. Does anybody know what this might be and where I

might get one?

Thanks for your input, Meryl

In answer to Meryl’s question about saw blades and Knew Concept saw

frames. I am surprised that you find the 4/0 size saw blades

gigantic for cutting 20 -22 gauge metals. Over here in the UK we use

metric sizes and if I am

correct 20 - 22 gauge is the equivalent to 0.50mm. - 1mm. in

thickness. I use 4/0 or 6/0 size Glardon Vallorbe saw blades for

cutting 0.50mm. metals and for 1mm. thick I will use 3/0 or 2/0 size.

I will only use 8/0 size blades for metals between 0.25mm. and

0.40mm. I tested the Knew Concept saw frames for Lee Marshall earlier

this year and wrote a report on Orchid. Here is a repeat of what I

wrote if you missed it; Today is the day I will give one of Lee

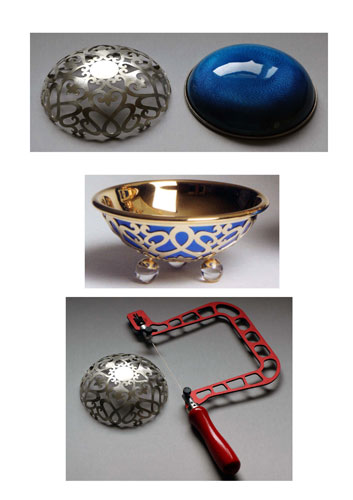

Marshall’s saw frames a good workshop test. My project is to pierce a

design from a five inch diameter, bowl shaped spinning of silver. I a

used the five inch saw frame, loaded with a 4-0 size saw blade. My

design has at least eighty interior shaped holes to cut out and the

silver is G25 thick. It took a little time getting used to using the

new way of fitting and tensioning the saw blades, but I liked the

feel of the saw frame, it’s lightness was a surprise and with the

simple screw tensioning system I was able to give a higher than usual

tension to the saw blade. I felt confident that the blade would go

exactly where I aimed it also. I was piercing for nearly four hours

and I did not break a single saw blade in that time. so without going

on too much, I can feel confident in saying that the Knew Concept Saw

frames performed much better than I expected and I would also say

that they would make a valuable addition to most benchworker’s basic

tool kit. The attachment is a couple of photos of the item that I saw

pierced with the Knew Concept saw frame.

Peace and good health and happy piercing to all.

James Miller FIPG

James,

The photos of your work stopped us dead in our lurking tracks!

Beautifully done, they are an inspiration to all who see them.

Rgds,

Ski & Cathy

Rocks to Gems