Gerry’s Diamond Setting & Observations!

Just what is a Diamond Setter? The Diamond Setter is a very skilled

person who is aware of the following jewellery disciplines;

_The composition of alloys, use of levers, tension of metals, use of _

_fulcrums, density of various working metals. Knowing how to _

_improvise & modify new Diamond Setting tools. He should have _

_some basic knowledge of soldering principles, uses of abrasive _

_compounds, electrolysis (Plating) and designing. _

_Along with these, he must cognizant of the following topics on _

Gemology with the study of crystals, porosity of materials during

_casting, knowledge of gemstones and their inherent hardness, _

_(Mohs Scale), load bearing limits on Diamonds, the uses of abrasive _

_& non-abrasive pumice wheels while using similar materials. Not to _

mention other uses of the basic burs!

Did I ever say that ‘our’ job is easy?

They should be aware of polishing techniques, how to subtly

enhance their own creations. A Diamond Setter is and should be a

designer, artist, creator of “Objects des Arte”. A setter should not be

in this trade just for the dollars, although this is important. He must

have a true understanding of what he is making. His labour, will on

the most part last longer than him or her, and those items that they

are working on will definitely be passed down to the next generation.

Once the craftsperson understands this, then they can be called a

“Quality Diamond Setter!” In this wonderful profession, we get

“instant gratification” in that we see in a few minutes from the results

of all our labour.

It is these setters who can transform a simple ring made of Gold or

Platinum into a piece of beauty, what many people will gladly pay top

dollar for. WE are the one of the persons who sometimes meet the

actual wearer and hear of the kind words of praise. On many an

occasion, I have seen a round disk with drilled holes in a row and

after 4 hours of labour transform this disk into a “Rolex” styled

watch-bezel worth thousands of dollars retail. Not too mention

setting diamonds into a Cartier watch frame, with the same exacting

quality. The very same instances drill over 300 holes into a Petak-

Phillipe watch bracelet then have this same item be worn in tandem

with a thousand dollar watch mechanism.

During the past 100 years, our tools of our trade have progressed

from a bow-activated, hand-pump to the now common ‘Micro-Motor’.

WE have also progressed from Bezel Setting all Diamonds to

Bead Setting our stones, to “Invisible Setting”. A five decades ago,

“wax setting” came into fashion, it has transformed much of our

intensive setting into setting these stones into a wax mount. We can

now set a thousand stones each day.

In this setters early years of learning his trade, he would have had a

mentor who will guide that person through the many different

avenues of setting. I had such a mentor in my earlier years. He

explained to me all the nuances of ”Bead-Setting”,

“Cut-Down”,

“Fish-Tail”

and Bezel setting, Princess-Stone Setting, 4 & 6 Claw

Engagement ring and Baguette setting. Many of his London,

England (circa 1940) techniques were passed down to me. I

incorporated many of his techniques and progressed these further

into the realm of teaching via classes and writing.

Diamonds also have changed in the past many decades, from the

“Rose-Cut” “Mein-Cut” & “Swiss-Cut” and to the popular “Brilliant”

cut. Along with these numerous shapes, jewellery designs have also

changed. We, the craftsperson, must change and create new rules

and methods in Diamond Setting must adapt to these new and more

modern patterns. If we don’t adapt, or learn newer techniques then

we will be left far behind!

Furthermore, we must know when to make a ‘single line-cut’ or

Milgrain style of finishing. When I have one bead out of place, it

could ruin the whole effect of what I am wanting to achieve. “Bright-

Cutting” is that alone “Bright”, with no interruption on the continuous

Bright-Cut. This specific method took me about 3-4 years to master,

bringing in new techniques of polishing gravers.

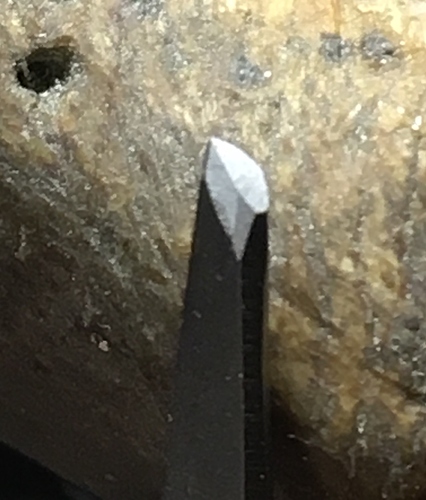

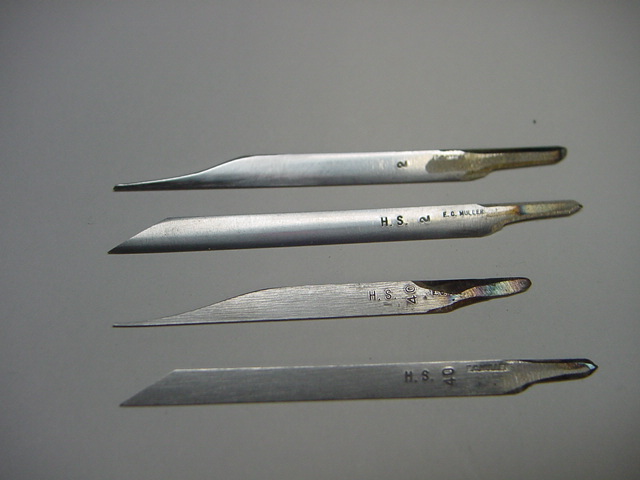

In my 9 years of apprenticeship I had to learn the subtle nuances of graver shaping

that was another 2 years of just learning how to shape them on a bench-grinder without

‘softening’ from heating the graver steel. This setter had to understand all of the subtle

nuances of polishing the roughly hewn piece of steel. Then to transform this blade into

literally a ‘surgical tool’ used for Bright-Cutting in 14kt, 18kt. & 22kt

gold using all with the basic #600, #800, #1,000 & #1,200 grit papers. This setter has to

know all of the different kinds of gravers to use when & how to modify at a moment’s

notice. This is knowing how to use the Emery & Polishing papers ‘when, where and

how’. Did I even mention the many uses of burs, ‘what size, when & how’? To decide

whether to use either a “High Speed Steel” (HSS) or to use a basic & generic “156C”

(Carbide steel) bur.

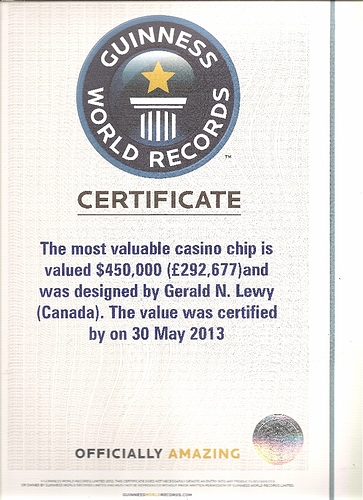

After an estimated 55 years of Diamond Setting & Designing, I created

and designed a “Guinness World Record”, May 30th, 2013.

It is now named“The Most Valuable Casino (Poker) Chip!”

Without any working knowledge of estimating the culet depths, spacing and

metal compounds, Laser-soldering. Also without knowing the advanced

levels of jewellery manufacturing & with the assistance of my Computer

Aided Designer (CAD) various sizes of the diamonds & qualities, this

certificate would not be made available to me!

Now you know now how just important it is to learn Diamond Setting. This

singular craft can literally open ‘new doors in designing & manufacturing’.

In a separate photograph, is my favourite Bezel-Setting of a 5.25 Carat

Pear-Shaped Emerald, set in 18kt gold.

!On the surrounding areas of this pendant were about 50 diamonds all ‘Bead-Set’. The cost

of that one single Pear-Shape stone was estimated (2005) at $8,000.00. In today’s

market, it would be in excess of $15,000.00. I was told previously that two other

setters refused to even touch it, why? It had numerous inclusions in and

in the Pavilion near the “Pear-Shape” point they both just gave it back to the

client & wholesaler!

BTW, it took me nearly 2.5 hours just to set that one Emerald stone.

“Experience in Diamond Setting, is based upon past challenges”. This

alone cannot be taught, but only learned! Experience from the past, gives the

setter a new road to tread and then turns this piece of gold into a pieces of

art. They should have the ‘feel’ of creating something of great wealth and

will have long lasting memories.

These are my personal experiences while at the setting bench. All of these

enclosed pictures show how I did the actual stone setting.

“All Setters must use appropriate thumb-guards while using gravers”!

Gerry Lewy!