My shop looks like a bomb went off lol

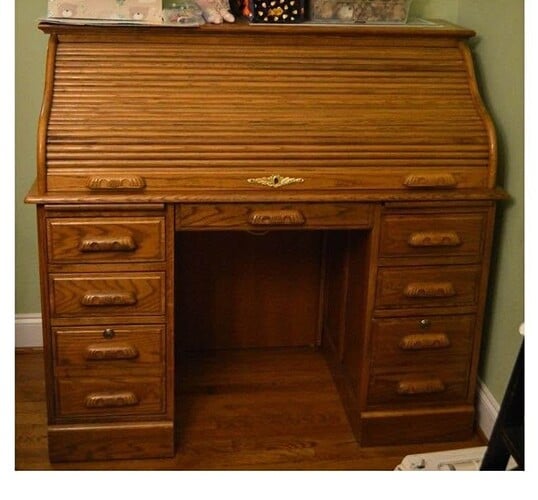

I got a great old rolltop for my birthday. I feel so bad altering it, but it’s so much more sturdy. I’m still struggling w the need for a separate power box for my shop and extra plugs. Any advice would rock.

A shop is very personal place. It represents your growth as an artist and reflects your approach to how you go about expressing yourself in whatever medium(s) you choose to work. Some of us are very specific about what we do and our shops are fairly simple in layout. Others of us chase interests and obsessions as they pop into our brain adding one more pile of “stuff” to help us explore that interest or obsession. Since retiring, I have tended to be the later as I have a lot of time and don’t make a living from my shop. However, I need to keep my shop very organized with everything in the right place. This comes from the fact that, prior to retiring, I was very busy with my career and went long periods of time away from my shop with very brief opportunities to use it. As a result, I had to keep it ready to use on a moments notice. The roll top looks like a great place to work. One of my benches was a large school teacher’s desk for a long time. Since you are posting on the Bench Exchange, you have had a chance to look at other artist’s shops. There is also a great book called “The Jeweler’s Bench Book” by Charles Lewron Brain. There are lots of good ideas in it. If I might make one suggestion it would be to but up more heavy duty shelves where you can store tools and supplies that you don’t use all the time. This will free up bench space and these tools and supplies will be where they should be when you need them rather than just moved out of the way for a project that doesn’t need them. Good luck…Rob

I finally got a little bit of order down there and now I’m fabricating the pieces that I need to make this into a good bench. I’m stuck on the engraving block holders since I currently can’t afford the GRS one at the moment so I’m trying to figure out a way to fabricate one.

Hi Kimberly,

I got a mini engraving ball and a bunch of stone setting tools and gravers a while ago and I’ve perched the ball on my bench pin a couple of times…which, as you know, is way too high, so I’ve thought about making an adjustable height shelf for the ball, too. I don’t think it should be too hard to do. You could use wood or a fairly thick acrylic sheet or even some aluminum sheet metal, which would be more expensive than the other two materials. My bench is an old watchmakers bench which has been reinforced with some heavy wood in the front, so there isn’t a problem mounting the shelf to something very sturdy. I just have to drill some holes in the right places so they don’t cover the bench pin slot or the hole for my mandrel and decide what kind of bolts or T-nuts or whatever I’m going to use to fasten the thing with. Adjustable height, with mutilple holes, like the GRS. I’ll take it as a challenge to figure out something cheap, and fairly good looking that functions well. I’m sure you can do the same!

-royjohn

Hi,

what about using your sweeps drawer as part of ball vise height solution…ie: put piece of wood over the top of it…or create a block to put in it…to create a surface for your ball vise

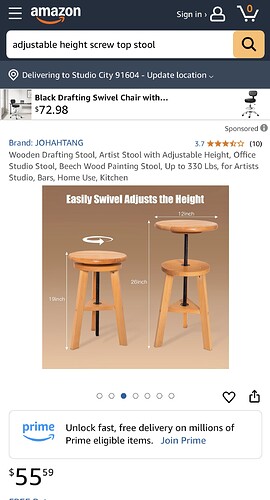

i have been looking for a adjustable height screw top stool to use…i saw a pic of someone using it for chasing and repousse…

needs to be tight…cannot wobble…

julie

Hi Kimberly,

Lots of techniques and materials, I LOVE the looks of your creative space! You’ll figure out what works for you and is most important and how it relates to your creative processes. I’ll bet you know where every thing is and if someone cleaned up you would be lost, like I said you’ll work it out.

Now your power problem, without seeing what your present system looks like I really can’t advise. The construction of your shop tells me that you probably have a main service panel that could. Possibly handle another circuit or two. If you take a pic of the panel with door open i I will be able to advise you…~~*STV

I gave in and bought the GRS system so now I have to put my drawer in the right place and likely need to add risers.

Ok awesome, I’ll do that. I was quoted $3500 for a second panel in my shop and extra plugs installed plus new fuses for my upstairs one. It sounds like a great quote to me but I was also told I could do what you’re saying.

Fuses? Sounds older than I was figuring.

If you have fuses your PANELS concern me . Be sure you get someone that knows what he’s doing.! Your biggest load , high resistance items like electric burnout ovens, heavy duty motors .

These are the problematic things that draw a lot of juice . The size wire used in the circuit, 10 gauge is usually used and they make Romex Some that can carry 2 circuits from main panel

and or feed a sub panel that can be fused and off that panel smaller wire, 12 gauge can be used for the receptacles (plugs) you spoke of. These are used for all the other stuff a person needs that doesn’t draw a lotof electricity. The biggest problem one has is using too small of a gauge wire for Stuff that draws lots of electricity this in turn heats up said small wire just like the coils you see in your heaters or ovens. Fires can. Start .

Your creative space doesn’t need half measures

Just as important if not more as the tools you saved and sacrificed for. Electricity is our friend and requires a great deal of Respect!!!..~~*STV

I had a 60 amp sub panel run to my shop several years ago. This fixed the ever growing tangle of new devices needing electrical access. Now my entire shop is fed by this panel. I have one switch that will turn off all the lights around my soldering bench for those times when I need it dark to anneal pieces. I do need to move my dop pot away so that it doesn’t turn off everytime I shut off the lights to anneal. If you have an air compressor running, make sure that you turn off the pressure switch when you leave the shop or it will come on at all times of the day and night as you will likely have an air leak somewhere. In extreme cases this can lead to a fire. Most of my machines like the ultra sonic and pin finisher have built in timers, but my SS tumbler does not. It is plugged into one those small rotary timers so that I can set it for a specific period of time and not worry that I left it running. I don’t trip breakers anymore, but I do have one circuit that it getting close to too high a draw if I leave a couple motors running at the same time, so I need rewire it. If you have cartridge or Buss type fuses it is time to look at having you panel updated. My house was built with 150 amp service. Most new houses have at least 200 amp service. I asked my electrician if I can upgrade to 200 amps and he said yes, but he would have to replace the underground conduit as it isn’t big enough for the size wire that feeds a 200 amp service. Lots of money, but I will probably do it to have the peace of mind that I have the service that I need. My first house had 60 amp service, but that was over 50 years ago…Rob