cross posted from FB

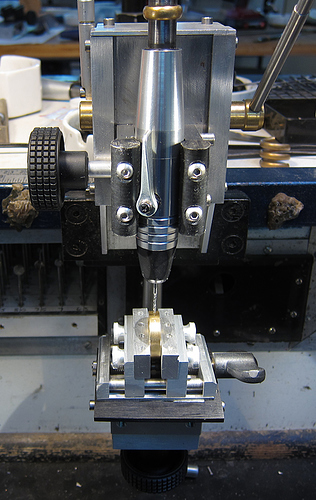

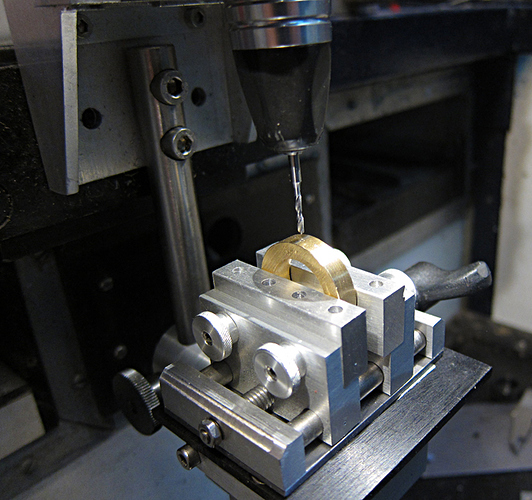

I made a magnetic switch table for the DrillStr8.

I modified a commercial switch for this proto type.

The magnetic switch part is turned on or off with a wheel at the bottom.

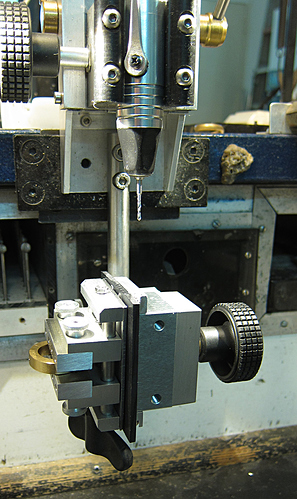

It has two diametrically magnetized magnets that are in resting state when it is turned off.

When the wheel at the bottom is turned 180 degrees, the magnets align and increase their strength and then it pulls at more than 50 kg’s.

I first just wanted to see if it works.

It does, so next is to lower the switches profile 10 mm flatter.

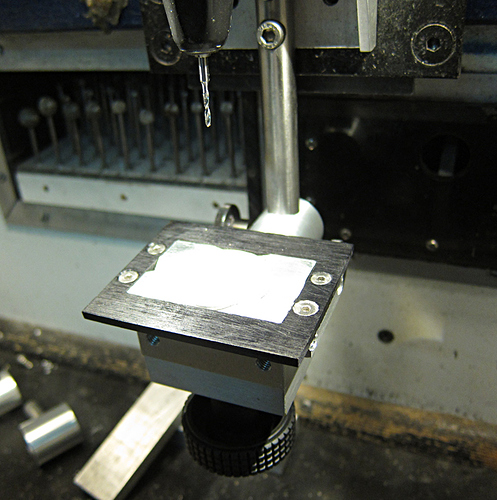

At first I made the black surround of this one out of 2 mm sheet metal, but is ruins the magnetic field and causes it to weaken.

In this model the black is perspex, which is not ideal because it is soft.

In the next version l will use 1 mm stainless steel.

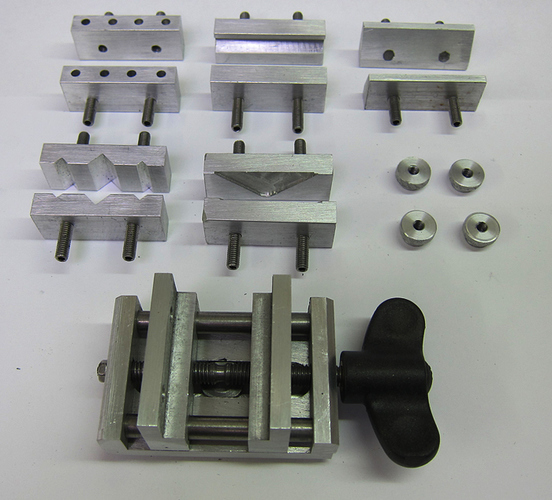

Ms. Vice.

Ms Vise is very attracted to Mr. Magnet.

I changed the bottom of the vise from aliminium to 2 mm plate steel.

The base is the same size as the iron part of the magnet , so it holds them really tight.

Still turns sideways.

When the magnet is off, the vice is loose so positioning it is easy and then when the magnet is on it freezes in what ever position you chose.

I’m just using a commercial butterfly handle to tighten the vice.

It works much better than I thought it would, though.

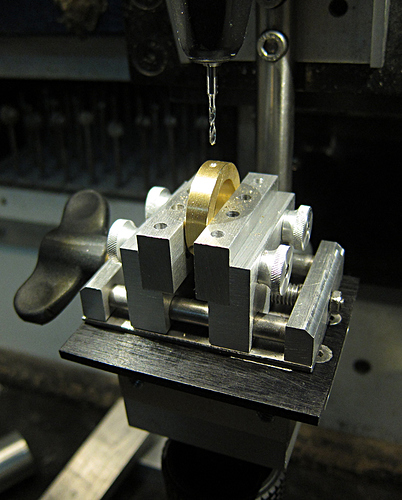

By default, this vise is center opening.

The screw shaft has both left and right hand threads.

Unfortunately, I have been unable to source good quality left hand thread die nuts that cut stainless steel.

They OK, but my right hand thread die nut is made for stainless steel and it cuts much better.

Anyway, the next proto type of this vise will have steel center screw.

This vise has five different jaw configurations at this point.