Andrew, Welcome to part of the world of LOST WAX CASTING

Normally vents are made by stretching the mold over a small diameter

post (piece of dowel glued to a base) and using a sharp scapel blade

to cut/pierce through the mold at the same time. The vents are then

held open and gingerly powdered with talc, corn starch, or baking

powder to keep them from totally closing up when the tension of

stretching is relaxed. This technique is used versus drilling because

drilled holes will leak and plug up after the first shot. I did

experiment one time, with mixed results, drilling and plugging the

hole with fine synthetic fiber to allow air to escape but wax to be

held in the mold. The patterns, shot this way, always had some kind

of flaw to be addressed before casting.

When venting a mold, in general, don’t forget to vent the piece near

where the sprue enters and even the sprue itself. This is the first

area of the cavity to see wax and last area of the mold to fill. If

there’s any back pressure here it can affect how the wax is allowed

to fill on the other sides of the mold.

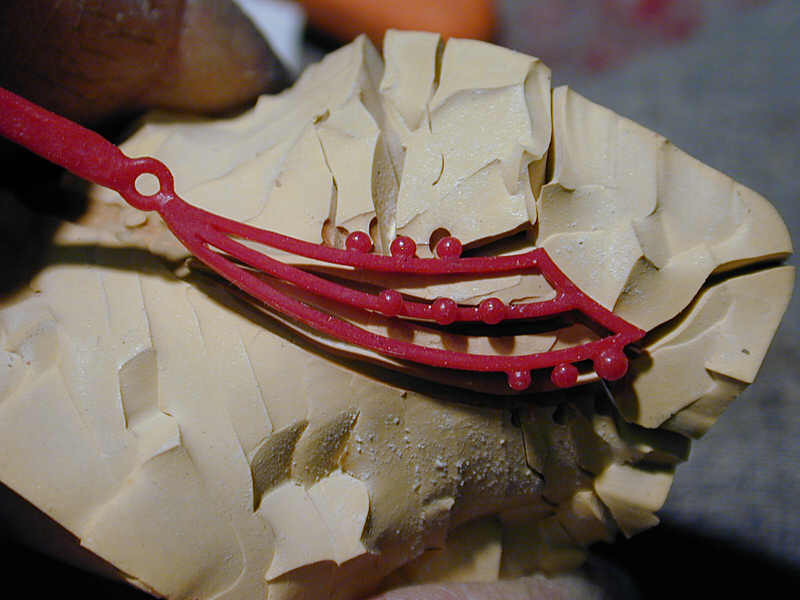

My experience has been that anything with raised lettering has

always been problematic in getting a good crisp CONSISTENT (notice

CONSISTENT) wax. The sharp corners of letters (and other designs)

tend to trap air and the surface tension of the wax resists being

pushed into the tight resesses. I’ve had to vent vent almost every

corner on some molds, which can lead to some extra marks being left

on the pattern to clean prior to casting.

This issue with lettering is why most emblematic lost wax jewelry

companies use metal molds and inject under high wax pressures and/or

vacuum to achieve consistent results.

And… your choice of injection wax and temperature can make or

break what you’re trying to inject.

Another importnt point to watch for is that your rubber mold makes a

good seal with the injector nozzle. If you’re losing wax here because

of a leak/poor seal, you’re losing effective wax pressure inside to

fill the entire cavity.

II don't have my own injector but I am looking at getting a new

wax injector (hand pump) any recommendations?

As far as I know there are 3 basic types of commercial jewelry

mechanical wax injectors.

In order of new price and reverse order of ease of use

A. Open hand pushed plunger pots (maybe $80-$100)

B. Lidded manual pump-up pressure pots ($200??)

C. Lidded pots with an adjustable regulator for connection to a

pressured air line or refillable air tank ($500+)

D. The Japanese vacuum type pressure injectors ($2000+)

All work well but A. does require some learning time to be able to

get repeatable results. C. is the easiest to use and produces the

best results for “average” molds.

Frank