Hi everyone,

I’ve been making jewelry as a hobby in my garage for 6 or 8 years and want to get rid of the small and very limiting centrifugal casting machine and build a vacuum casting machine (a recessed table version that can use the bought perforated flasks).

Is there a guide or DIY build I can follow along that anyone knows of? Whether in a book or online? I’m pretty handy, I built a motorcycle from the frame up when I was young and do a lot of soldering on plumbing for repairs so I can do fine for the vacuum release lines/valves. But I think it would save me time if I can use someone elses example.

I guess since I plan to purchase a perforated flask, I start with the size of that flask to make the recessed box and work from there.

I want to use the recessed version to both get the bubbles out of investment and then use it for casting.

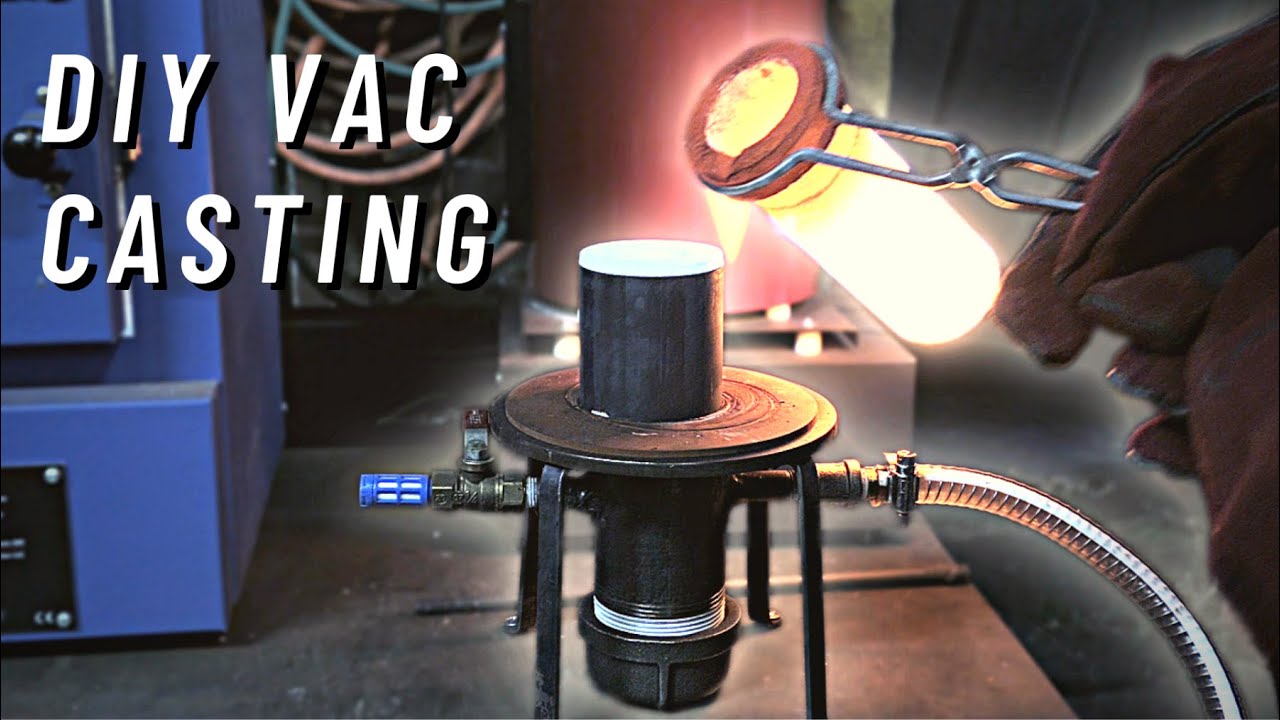

This is the simplest I found so far. But think I should maybe build a bigger box for the vacuum machine to inside of. And I would hard solder the bottom to make it airtight at the bottom.

thank you!

1 Like

I have a vaccum casting machine for sale…if you or anyone here is interested, I’m in Washington state…it’s been only lightly used, as plans changed soon after purchase…I’m willing to let it go for a very reasonable price…thanks for any interest…

I have a vacuum casting machine. It’s an easy DIY project if you can find an aluminum “well” to put the flask in. You’ll also want a polycarbonate dome to pull vacuum for your investment. Besides that, everything is easily obtainable/makeable.

I’ll PM you. I’d have to pay for shipping might I might still be interested.

If others need it, I think I found the best one but is none perforated (my kiln is small anyways so it limits me to small flasks so non recessed/perforated is fine).

If you have limited tools and limited materials, this is the best DIY video I’ve seen:

There is another great one but it requires a full machine shop.

1 Like

I worked in a large manufacturing facility. We built our own vacuum caster It worked great.

We cast up to 100 flasks a day but normally <50. We did not use perforated flasks - they’re ridiculously expensive! We bought lengths of stainless tubing and had a “home machinest” cut it up and dress them on a lathe -a whole lot less than $45/flask! But we did want the vacuum pulling through the investment so we used plastic straws and Bobby pins. Dipped the end of the straw in wax and clipped them to the flask between the rows of waxes. We had consistently excellent results. Plus you don’t need a machine shop to build it.

3 Likes

Im looking for one if the OP didnt purchase.

Thanks for reminding me of the plastic straw trick. Since this is a hobby, I have to keep costs low, great idea.

I got lucky and found an old but well made Kasto-Vac vacuum casting machine. It works but the switch is going bad, I can easily replace the switch.

I tested it and without cleaning the bellhousing bottom and the surface, it’s pulling about 22/23 cf/hg. Is that a strong enough vacuum for 2.5 by 4 inch flasks? It looks like it has an oil viewing glass window and it’s very dirty. Are all vacuum pump oils the same? The vacuum motor looks different form the cheap HVAC ones you see now but can I use the same oil if I change it? Also, there is a glass tube inside the cabinet. It looks like there is metal pieces in it. Is this part of a medium for a filter or is this actual precious metal that has gotten stuck in the glass jar?

If you’re at sea level you should pull close to 29” - you lose an inch of mercury for every thousand feet. That being said, vacuum is vacuum and in Santa Fe at 7,000’ casters still get excellent results. 22” works here!

1 Like