Thank you !!!

Now next step question. I have a table. Desktop is a piece of plywood and on the top is a thin 16 gauge sheet of steel screwed and contact cemented to the plywood.

I have coming from vacuum pump a hose ended with 3/8" OD copper piece ( fitting is just smooth metal ). What is the best way to insert this fitting into the table?

1)First i thought about some plastic insert - to insert the plastic into hole in table and the fitting will go very tightly into the insert. Fitting and insert are made professionally and part of vacuum press for wood laminating. But i am not sure if the plastic insert will be able to sustain flask temperature.

2) Another idea is to drill a hole in the table the same diameter as OD of the fitting ( actually 0.5 mm less) force the fitting in the hole and then somehow solder or use liquid metal to seal possible leaks around the fitting.

Guys what would be your ideas how to do this better. I have ZERO experience with vacuum fittings and don’t know which to buy and where to buy. please help.

-Boris

I would think about 1 1/2 to 2" steel plumbing pipe. You can get 4 bolt flanges for those. Bolt it under your cut hole and thread in a short pipe down to your pump. You could even put an elbow or a T with a cap down there in case you have a flask blow out. You could unscrew the cap and get your metal and investment out.

In a purchased vacuum caster the vacuum is pulled with small diameter plastic tubing. The advantage there in the fittings are small. You don’t need a big hole in the table. Brass plumbing would work and you need a valve to release the vac anyway so go play with some fittings at the hardware store. Shannon

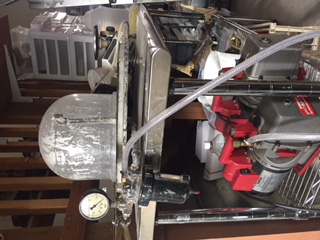

@Borispitel Attached are the pictures. Sorry for the delay, Got sidetracked with G-Kids.

A few explanations

The first picture is of the vac table with the rubber mat in place when I ready to pour I change to a smaller silicone mat just a bit larger than the flask.

The table is 12" X 12" and 0.49" thick steel

You can see in the corner with the caliper that there is a screw head. It goes through the steel, then through a spring, then through my cart/table and has a double nut on the bottom which allows for giggling the plate.

You can see the 4 screws, one in each corner and the center hole for pulling the vac.

Another picture shows the steel plate with the rubber mat and the vac dome

The final picture shows the underside of the table where the vac lines come into the table. The other post @scavengerqr using a T is absolutely correct. I have only had a couple of blowouts while pouring my metal but I was able to recover all of it with the setup as shown.

In response to the question on vac fittings, think of it as pressure in reverse. All of my pipe joints are sealed with teflon tape and I haven’t had any issues. I do not use small diameter fittings or hose. One other improvement that I may add in the future would be a canister to build up vac prior to opening the valve for casting, this would allow the flask to reach a critical vac faster.

Vacuum investing tables usually have a pipe

several inches above the surface so

investment overflow from flasks cannot

go down the tube and create a blockage,

that is why there is a table for investing, and

a separate table, actually a cylinder that the

flask sets into for vacuum casting.

This is the vacuum investing table I built.

Two pieces of plexiglas with an aluminum

plate on the top, springs between the two

plexiglass sheets. Sheet rubber from the

hardware store for the bell jar to rest on.

Very thick piece of aluminum, unfortunately

it had enough of a very gentle curve, not

observable, so it would not seal. Took it to a

machine shop and they used a hydraulic

press to push the curve down to flatten it.

I have used this for over 20 years,

5 cfm pump.

I did not need to put a water moisture filter

on it.

Thank you. Very useful

-Boris

Good news!

Did my first vacuum casting at home. Everything went very good. Except trying to make it even better i decided to adjust the flask a little bit while it was on a vacuum table with … my bare hand. You can imagine the smell of the burning flesh. My flesh. not good.

Damn! I hate that smell. Especially my own:-)

Jo