Hi Trish,

I want to come in here as from afar, here in Dorset UK, its so painful to see you struggling with simple tasks that are really only a supportive function to your main work. Now if you had had an apprenticeship, in any sort of mwetal w/shop your first tasks would have been making the tea, sweeping up and going to the forge for a bucket of blast, for the foreman, you would have seen all the metal workers using tools, one of which was essential for their task.

None of us have the strength to master most metals, thats why H. sapiens invented tools

now from your description, you are lacking the 1st and foremost tool all metal workers should have, and that is your 3rd hand.

whats that you may ask?

Its a proper vice , now the most useful one is the smiths leg vice, look it up,as they come in all sizes, from 2in to 8in jaws

for a small worker like you a 3 in would be fine tho a 4in is better.

It does need a proper w/bench from 4 by 2.

so for example your titanium strip held in the vice, all you need is a few taps with a hammer to bend it to 90 deg. Repeat on the other side. then close up till they touch. A clamp takes less than 1 min to make. I presume you have several hammers?

Now where to find one?

In the U S of A on ebay, there a stupid price,

your best bet is to track down a local iron smiths w/shop, now we smiths whatever we do we collect tools, and most of us may well have spare vices put by.Its the way we do stuff,

Then to someone deserving well, maybe! with a nice smile, part with one if its going to be used and a good home.

get out there and see what you may find.

get back here to report your luck

Ted.

Hi!,

here is a link to an interesting video demo for these strips, by Andrew Berry

at about 4:30 minutes into the video, he shows bending and shaping the strips.

Julie

Hi Trish,

Any tool, any time.

At one point, I yanked the jack out of my hydraulic press, and used it to help me move a bookcase around.

(needed to jack it up a little, and didn’t want to unload it. Thus…) I’ve used the vacuum pump from my casting rig to help clean Victorian military uniforms.

Remember, we are tool using mammals.

Remember also that we metalsmiths have one critical advantage over all other crafts: our tools are made of metal.

So we already have the tools on hand to make, or modify, any tool we want. Any way we want. Remember this.

Regards,

Brian

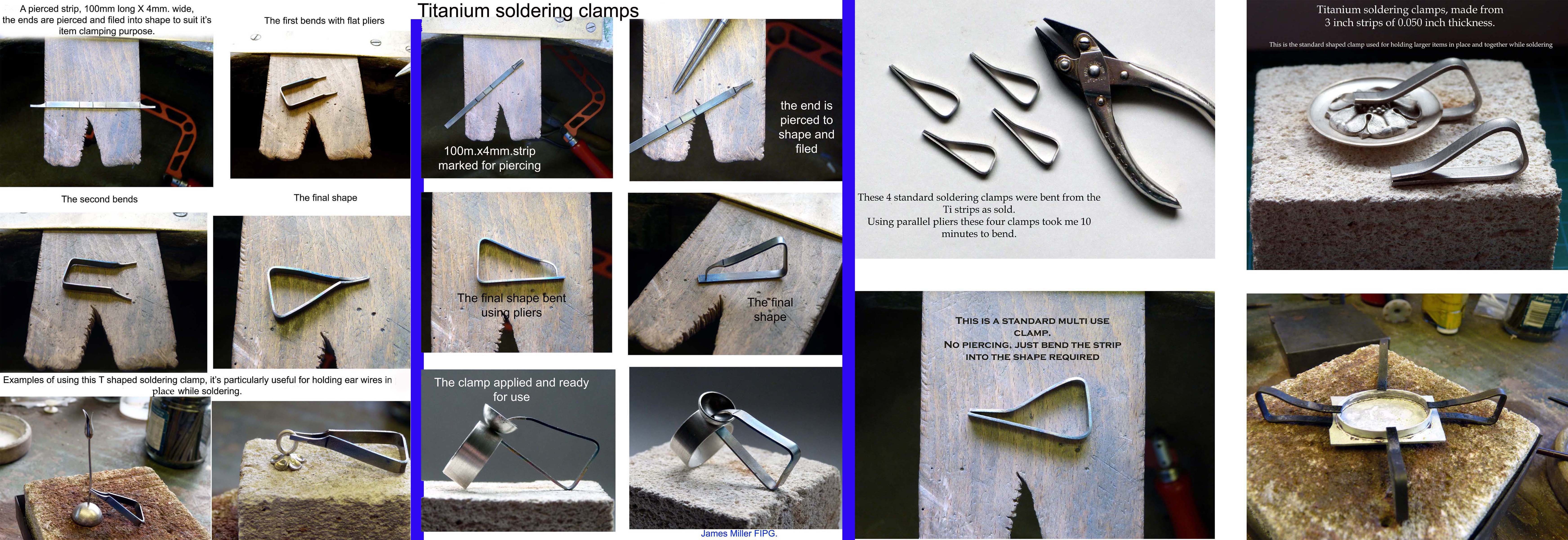

Here’s another YouTube video on how to make clamps.

So I bought these things MONTHS ago and have been soooo nervous about even trying them as I have heard SOOOO many horror stories about how some folks cannot bend them.

I think I’m in this weird state where if I don’t “know” then I don’t have to face them if I have one of the batches that don’t seem to have been annealed correctly. I will just have to bite the bullet at some point and throw all caution to the wind I suppose and be brave and just get over it and DO it.

I hadn’t read this thread before getting my strips from tamizan here in the UK - so I was really surprised to hear that people were worried about them being difficult to form - because they aren’t! I had no problems bending them with pliers or sawing them with a regular jeweller’s saw blade - and I am just a weakling hobbyist - so if I can do it - anyone can!

Sally

Hi James,

I Just wanted to thank you for such a useful tool & the development of the logical variations.

You are a contribution to us all.

Thanks,

Jim.G

I followed Leslie’s video months ago when I first bought mine, but her instructions didn’t work for me. The manufacturer says these are already annealed and further attempts can make them brittle. Also, sawing into the places where you plan to make a bend will probably also make them break. Several of mine broke. Then I asked a friend of mine who works at FDJ which is near my home and he suggested some other ways to work with them (basically a strong vise and a rubber mallet).

I did find them very difficult to make any clips that resembled those in the photos, but there are some other videos out there that are helpful. In fact, I was pretty sure that I had seen a rather lengthy thread here on Ganoksin that included comments by the manufacturer, Knew Concepts that were very good.

I recently bought a GRS soldering station which is primo and handles all of my soldering clip needs. One of my best investments.

Great information and discussion, all. Beautiful clamps, @jamesmiller046. And @alberic, thanks as always for the deep background on Knew Concepts tools. I just ordered a set of strips and trivets.

Alec

I received a new set for Christmas and have been able to bend them. Not with ease (I don’t have great hand strength), but easily enough to get most configurations I want. And there’s always the vise and a hammer.

I had an old set that was one of the originals, and they were much too thick for me to bend. At all.

Recommend trying a new set if you have not had success with the thicker ones. They are very handy!

Tricia

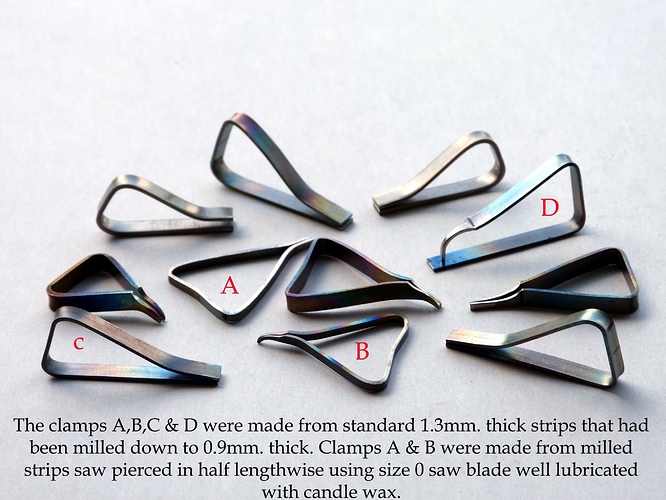

I am sure that you will find the titanium clamps useful. I do mill some strips down to a thinner gauge for making different clamps.

James

I should add that it was the pictures of your clamps that convinced me to buy some. They’re excellent examples of what these clamps can do.

Thanks again,

Alec

Alberic/Brian,

Thanks for the info.

A suggestion: In general (i.e., anywhere you give dimensions), perhaps you could give metric as well…:-)…?

Janet in Jerusalem

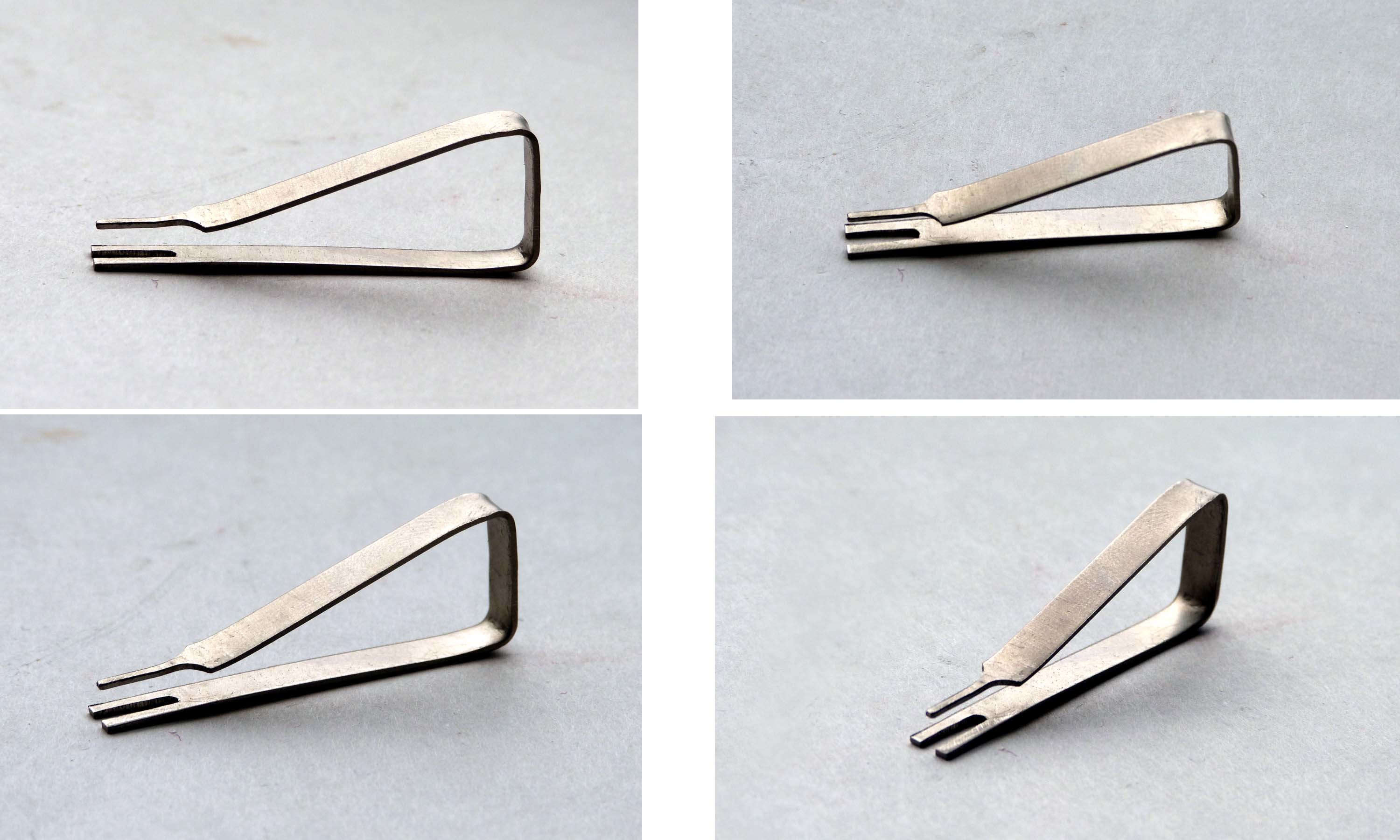

Though not anywhere as beautiful as the clamps James made, I think this is going to do just what I need it to.

For some reason, I thought that cutting Ti was going to be difficult, but it cuts and files nicely. I’d like to improve my bends, however, something a little sharper and more regular. Practice, practice, practice.

Alec

Low cost/low tech alternative.

In my first metalsmithing class 20+ years ago we were taught to use metal hangers to accoplish most of what is done with the titanium soldering clams. We’d cut about a 3" strip, flatten the ends with a hammer, file smooth and bend the clips in half, tapping on the bend with a mallet insure tension before putting them toi use. While I doubt that zi have any from 20 years still have some I made 5+ years ago.

Yes you can make soldering clamps from any metals, before I started using titanium I used stainless steel, before stainless steel I used steel cotter pins, before using steel cotter pins I used iron wires. The benefit of using these ttanium strips is that they do not degrade through a lot of heat use, they cannot be soldered to an item and they do not distract heat from the soldering join. So to me they are well worth the investment. Sorry if I have posted this photo before, but it shows the variation of clamps that I use.