Thank you, James Miller. Yes, I purchased some a few months ago and have used various combinations of pliers, hammers, etc. to form them into rather crude approximations of some of those shown in your photos. I tried annealing and decided I was not reaching proper temperature (or something) as it made little or no difference. I’ll persevere though because I do find them very helpful. Mine will Never be as elegant as yours, but I suppose I already knew that

Thank you again, Patricia

I was excited about these and contacted Knew Concepts only to learn that they sell the titanium strips without modification. I’m not interested in sawing and bending them but I wouldn’t mind paying for a set that are ready to use.

Hi guys,

Sorry for replying to this so late, I’ve been down with the flu.

I’m not sure how the new email system is going to interfere with my normal procedure of using this account (Alberic) when I’m talking for me, and the Brian@knewconcepts account when I’m talking for Knew Concepts. So for the moment, I’m using the Alberic account. Just to be clear, this is actually Brian Meek, the other guy at Knew Concepts.

As far as the titanium strips go, believe it or not, they really are already fully annealed. Nothing you can do to them is going to get them any softer, short of trying to bend them at red heat. (Which will make them brittle if you get too enthusiastic about it. Try one and see what your results are.)

We’ve tried using thinner material, but the thinner ones are not as strong when hot. We haven’t decided if we’ll make those available or not. Opinions among our testers differed. One or two loved them, and the rest thought they weren’t strong enough.

I can bend the normal (thicker) ones bare-handed, and quite easily in a set of pliers. If you’re having serious trouble, cheat: use a vise and a big set of hardware pliers. More leverage is always better in situations like this. They don’t have to look pretty, they just have to hang on to whatever you’re using them for. I’ve seen them used as ring clamps just by turning them into a loose spiral ring, like a badly wound jumpring. Ugly, but entirely functional.

James’ clamps are beautiful, and beautifully worked out, but they don’t have to come up to that level to work well.

As far as pre-formed ones, sorry, we won’t be making any. The whole point of them is to make customized clamps for whatever specialized need you have right now. If we did pre-mades, they’d be wrong much more often than they’d be right. The other issue is we don’t have the equipment for making pre-formed ones at any sane price point. (We have many cool toys, but we don’t have them all, unfortunately.)

We’re glad everybody likes them, and we really are trying to make them easier to use, while retaining the strength started the whole thing. If we come up with anything radically better, believe me, we’ll get it out as fast as we can.

Regards,

Brian Meek

Knew Concepts.

From Janet to @Janet_Kofoed

I put the strips down for my next @RioGrande order but am having second thoughts after reading the posts here…:-(… Since you were able to work them easily, could you perhaps give us some input on your technique? Particularly, did you use regular saw blades? What size? Did you bend them by hand, in a vise etc.? Did they file easily? Did they screw up your files at all?

Thanks for your input!

Hi Brian,

What is the thickness of the strips? @RioGrande just shows:

Dimensions: 4"L x 3/16"W

Thanks.

Janet,

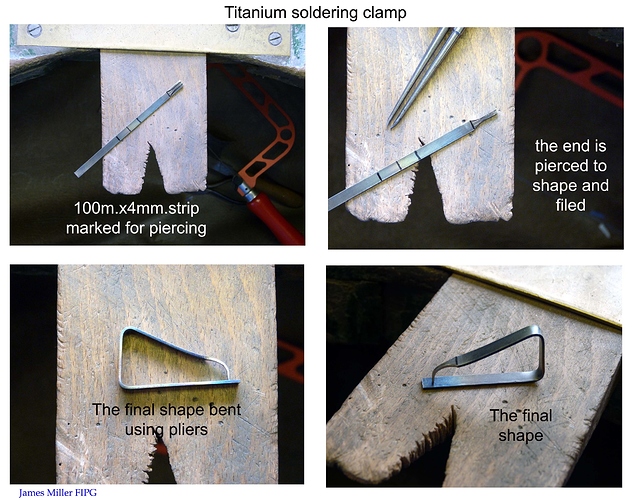

The titanium strips are close to 1.3mm. thick, I pierce the tips to shape with a size 0 saw blade, well lubricated with candle wax. I use an old 6 inch crossing file to finalise the tip shape.

This is another shape clamp I use often.

James

Thanks!

Janet in Jerusalem

I used regular saw blades, #0, and I bent them in a vise. i had far less trouble with them than I expected.

Janet Kofoed

(Which will make them brittle if you get too enthusiastic about it. Try one and see what your results are.)

You do not have to heat them to a red heat to greatly reduce the amount of force needed to bend titanium, 800-1000F will greatly reduce the needed force. It is called warm forming and you can find more about it on the net.

James Binnion

jbin@mokume-gane.com

James Binnion Metal Arts

360-756-6550

Hi there, Tricia. Knew Concepts has a pre-bent trivet. I got one, but haven’t tried it yet.

Hi, cirious,

Thanks for that. I do have their trivet and love it. It’s like an enameling trivet, though, and not for clamping.

Tricia

Hi, Brian (et al),

This definitely helps answer my question.

I guess my hand strength is much less than I thought!

Using a thinner gauge titanium (or maybe even wire) might be worth experimenting with, especially with smaller jewelry pieces.

I need to place an order with @ReactiveMetals anyway, so I’ll add in a few bits of titanium to see if they will work for me. Now I’m thinking maybe being able to form a few T-pins out of thinner wire…

This is such an exactly-what-I-need idea, that I’m not going to give up just yet, wimpy hand-strength or not.

Thanks everyone for your help and great ideas.

Tricia

Hi Trish,

Don’t put yourself down. You don’t have to be strong, just smart.

Once upon a time, when dirt was young, and rocks were soft, I apprenticed to a blacksmith.

He claimed-credibly-to have been the model for “Hagar the Horrible”. Arms the size of my thighs. (really)

I once watched him belly hug a 55 gallon drum full of coke and walk off the trailer with it. Not anybody’s idea of a lightweight.

We were doing the state fair one year, and frequently got the question “do you have to be strong to do this?” to which his answer always was “nope, just smarter than the metal”. (frequently said while pointing at me. Then 6’1", and might possibly have weighed 160 pounds sopping wet.) (No more, unfortunately.)

The biggest muscle in your body is your brain. Use it. If your arms won’t get you there, use something else. Legs, a bigger set of pliers, a pipe, a bigger hammer, something. What’s a hydraulic press? A bigger hammer. You get the idea.

As far as the preformed ones go, I may have spoken too finally. I did come up with a way to let us make preformed ones, but, it relies on (A) being able to convince the titanium manufacturer to make custom rectangular Ti wire for us at some sane price point. (Don’t hold breath) and then (B) whether or not a small (merely $5000) CNC wire bending machine has enough ‘oomph’ to bend the Ti wire into shape for us. (and to survive cutting it off when done.)

If (A) and (B) both work, then we might get preforms out sometime early next summer. (really. It’ll take that long to get the kinks of the system.) So don’t hold your breath right now, but if it turns out to be possible, we’ll do it. We’re not morally opposed to them, it’s just a matter of money and technology. If those two stars align, then so be it.

Regards,

Brian Meek

Knew Concepts.

PS–> my original intent in this was to give the dimensions of the strips. They’re .050"x.190"x4". (more or less) The first production batch were .060" thick, but we dialed that back to .050" as soon as we heard people were having trouble with bending them. The “too thin” test batch were .030".

Hi Brian, its Ted,

Just read your post to Trish, and you ps, theres no need to go down the CNC etc route to preform, all you need is a hinged tool held in a bench vice like an upside down t which holds the strip when you clam up the handle. Just tap round with a hammer. to get the 1st 2 bends, the rest of the forming will depend on how you mean to bend it and the shape of the tool

I do this on a number of my forming of metal parts, so for your needs. I could run off 150 an hour by hand for this soldering jig with no sweat. in .050 titanium? by .5in wide. so easy.

We shouldn’t have to teach folk here the basics of sheet metal work. It’s all in books.

What happened to the workshops schools used to have? metal working for boys and sewing plus needle work for girls, tho both could do either here in the UK.

just to mention put together a hand press to bend 2in by 1/2in steel bar to 90 Deg cold.

Hi Ted,

I agree with you about the lack of workshops in schools here in the UK, I learnt many basic shaping methods while in my school metalworking classes.

As for bending the soldering clamps, I get many queries as to who sells ready made clamps and I try to explain that they are not that difficult to shape. I have just done a test bend, using one of Brian’s titanium strips a pair of Maun parallel pliers and my desk. I marked out where I wanted the bends to be on a T shaped clamp and gripping the strip in the pliers and pressing down on my desk I managed to shape a T shape soldering clamp in 45 seconds. Obviously if I pierced some points on the strip first it would take a few minutes longer. One benefit of just buying strips to shape is that you can make any shapes that you think may be useful when soldering, bending and shaping metals is something I have been doing for the past 55 years.

I just heard about Kickstarter.com. Check it out. If it becomes feasible, it might be a great way to fund the project. Just a thought…

GREAT idea!!! Thanks for sharing!

I’ll be getting 10 of these on my next @RioGrande order!

Thanks, this is great for my jewellery class.

Fiona

Hi Ted,

The CNC is for a couple of reasons.

(A) to rapidly make several different types of clamp, on the fly, with changes easy.

(B) to do it without anybody having to tend it.

There are only 4 of us, and Lee and I are usually busy, plus Tim’s putting saws together (all hail Tim!) which leaves…

Only Ray, if he’s not doing something else. (like tending the other CNC machines. Some of which are grumpy, and like to feel like someone’s paying attention to them.) (Hint: do not annoy 12,000 pounds of computer with a bad attitude. It gets expensive.)

Regards,

Brian

Brian, thank you!

First, relief because, yes, I do have one of your first batches (the .060" ones), which helps explain the differences in my experiences from others in trying to bend them.

The pep talk was nice, too, since I occasionally do discover myself in the Slough of… let’s call it Befuddlement and have to step back before I can see things more clearly and figure out a solution.

My vise is a small clamp-on one, and hasn’t worked with the titanium, but I do have a hydraulic press, which, though smallish, may help. Thanks for mentioning that – I’m not sure if I would have thought to use it in this instance.

Fingers crossed the pre-formed ones can become a reality. I will definitely be in line for those, if they happen.

Tricia