Hi,

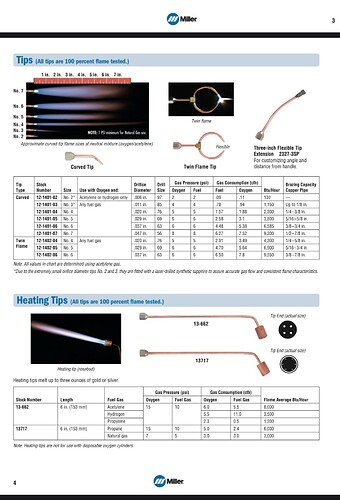

here is some Little Torch info from millerwelds.com

look under

equipment/ oxy-fuel equipment/ oxy-fuel specialty outfits/ little torch/little torch basic outfit, B fittings

and then click on spec sheet

it says 4 psi for oxy and propane, 1150 BTU/hr

your tip may be blowing out if the psi is set too high…?…

I have been trying to melt about 4 oz of sterling silver with the below torches, and was just curious about their BTU and temp and PSI…dont quite the inner workings yet…

using the Smith Little Torch:

-rosebud tip spec says

oxygen psi-15, propane psi- 10, 6000 BTU/ hr

-#7 tip spec says

oxygen psi-8, propane psi-8, 9200 BTU/ hr

i am waiting to recieve the Smith AW1A Versa Torch, with AT61 threaded neck

- to use with my Paige MX melting tip

I do not know the psi requirements, or BTU for the MX tip

…and my propane is on a non-adjustable disposable regulator and i am not sure what the psi on the regulator is…yet…it kinda seems like on or off…not sure if turning the knob affects the PSI…will call Miller tomorrow…

the spec sheets says, using Smith AW1A Versa Torch with their threaded AT61 neck:

(i do not have the below tips…i was just reading this on their website)

(these could possibly be too hot/ too much for my jewelry needs…i do not know…)

-with their 13715, 4-hole tip says

oxygen psi- 38, propane psi- 12, 16,600 BTU/ hr

(i have never used this high of a psi before…)

-with their NE164 single hole tip says

oxygen psi-10, propane psi- 10, 27,500 BTU/ hr

i dont understand it all…but would like to learn…

i think other contributing factors are:

gas types

torch valve size

how heat reflective your surface is

crucible size/ mass relative to melt amount

…

julie