Well, I did it. I left the pot of water and my GRS thermo-loc on the burner too long boiling it dry, filling my shop with smoke and wrecking the thermo-loc and the pan. The scary thing is that I am so deaf that I didn’t hear the smoke alarm until my wife came down yelling at me. Always a scary thing. I decided to replace the smoke alarm with the kind that includes a strobe light. I already replaced the one in our bedroom with this type of alarm. Since I need to replace my thermo-plastic, I am looking at other options first beside the GRS product. Jett Sett now seems to come in two different kinds and there are a bunch of other options on Amazon. Any thoughts, suggestions or ideas are appreciated before I make another purchase. I like the GRS product, but it is a chore releasing the piece that I am working on once done, especially if it has a lot of parts to it like a multi wire bracelet. Thanks…Rob

I follow an account called Hazel.handengraving. They do hand push engraving at a very high-level and they have to hold and release many items a day. They use green dop wax and heat it up with a small hand torch and then pop it out when they are done. Wow, the green wax is still setting up. They will put little holes into it that later they can use to pry the peace out with. If you look up their account on Instagram, you can find videos of them doing this.

You can find it on eBay and probably other places.

I currently have not tried to use it, but it looks quite handy with the speed you can hold things and release things.

Thanks, since I am also a lapidary I am familiar with dop wax. I have tried it and it is even more of a chore to get it out from behind a bezel on a multi wire piece of jewelry than thermo-loc. It does release nicely from a flat surface, especially if you put it into a freeze first…Rob

Ah yeah that makes sense. I heat up my themo loc with a heat gun. Have you tried that?

I have tried boiling water, a microwave and a heat gun. For me, boiling water works best as long as I turn it off at the right time…Rob

I have a programmable thermostat controller thing that you could put the probe into the water and when it reaches a certain temperature, it could cut power to the thing that’s boiling the water. Would that work?

Hi,

so, my observations…

-

jett basic softens faster, and is sticky…good for holding onto small fidgety items. it is stickiest when transparent…as it cools it goes opaque…it is easier to pick out of crevices with a toothpick, after it starts to go opaque…at that point it will peel off in more continuous bits, rather than making a sticky mess. you can simply push the piece into a kind of opaque jett basic, shallow, and wait for it to harden…the stickyness make it grip when item is very lightly embedded…it does not “shrink back” like jet ballistic or thermoloc…allowing for shallow delicate embedding…you can tell when just the shallow surface starts to get transparent/ sticky…it does not have to completely wrap around elements…if it cups it, it can hold…the stickiness helps it get good contact…is my favorite for this type of work…it slso doesnt take alot to soften the surface of it back up…

-

jett ballistic is similar to thermoloc…i prefer thermoloc as its consistency upon heating is more…consistant…homogeneous…

i have a harder time getting jett ballistic to the proper consistency…it tends for fold onto itself but not meld together…like…crumpling a ball of tin foil…it makes a ball but the folds stay separate from the whole…

they both have a tendency to sort of shrink back as they cool (in my experience…i am sure it has something to do with my not heating it enough…)

when heating the embedded item is not an option, having a release strategy is important…such as:

-

having a channel under the piece, creating a thinner area that can flex like a hinge, with the channel also providing access to

stick a tool in, to help pip the item out -

creating a two- part holding solution, that will come apart for releasing the item…using saran/ plastic wrap as a barrier between the item and the thermoplastic prevents the thermoplastic from going into underut spaces that will make release difficult.

orange shellac and dop wax are also good…they have the sticky factor…and when the item to be released can not be heated, it can be chipped off…and perhaps then carefully cleaned up with solvent….

heavy double stick tape has also worked for me…primarily for flat briad surfaces…although it did hold my 6x8 open bottom bezels…

julie

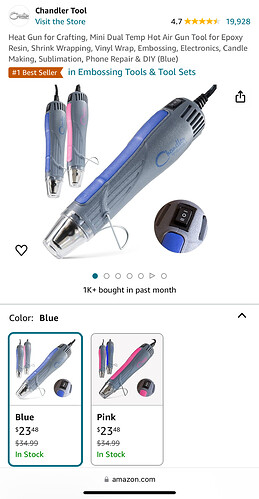

I use this small heat gun instead of boiling water with thermoplastic. I find it much easier to use. I have even used it with opals. It is easy to just shield the heat from the stone with a piece of cardboard until the plastic is soft enough to allow the piece to pop out. I find that residual plastic just pops off once you let the piece cool.

https://www.homedepot.com/p/Wagner-HT400-Precision-Heat-Tool-0503038/304216733

I have been through a number of heat guns melting pitch in a pitch bowl. They seem to shut down on high heat just about the time I really need them to stay on. One time I hung it back up on the hook and it cooled down enough to come on and melted the power cable. I think that you may be right about using them for thermo plastic so I will look for another one. I use my small butane torch to heat the pitch now. Thanks…

Rob

Hi,

i have the wagner furno 500 for heating pitch

but, i wanted something smaller for heating thermoplastic, so i got a craft mini heat gun. this one works well for me.

julie

I thought thermoplastic pellets from Ali express. I am very happy with them - using them for holding work and to mold handles for tools, and for crafting.

NZ$20.54 | 500g/1000g Polymorph Thermoplastic Friendly Plastic Aka Polycaprolactone Pellet DIY Ceramics Tool High Quality

I used to use these in architecture school to quickly model stuff. Very cool

At Hatton Garden, I always used red setters wax (probably from Cookson’s) for holding items.

The advantages - it breaks up afterwards cleanly and quickly (an ultrasonic bath not usually necessary) when the piece is dropped into ordinary meths (denatured alcohol). And it’s very, very sticky when hot. You can use a wet finger to push the plastic hot compound into place if necessary.

The main disadvantage - the intrinsic filler (brick dust, I was told) can ruin a hand or motorised graver tip if it so much as touches the cold compound.