Hey guys!

New with casting gold here, and my question is how your workflow would look like when you wanna alloy and cast your own 14 karat gold.

When I search online i see that the best casting temp for 14 karat Yellow gold will be around 900 - 1000 celcius, depending on Centrifugal / Vaccum, size of casting, thickness etc etc etc.

However, now I stand with three fine metals I wanna alloy together with different flow & casting temps.

Fine gold

- Melting Point - 1064 degrees C. / 1945 degrees F.

- Casting range - 1160 to 1170 degrees C. / 2120 to 2138 degrees F.

Fine silver

- Melting Point - 962 degrees C./ 1762 degrees F.

- Casting range – 1050 to 1060 degrees C./ 1922 to 1940 degrees F.

Copper

- Melting Point - 1085 degrees C. / 1985 degrees F.

- Casting range 1150 to 1180 degress C. / 2102 - 2156 degrees F.

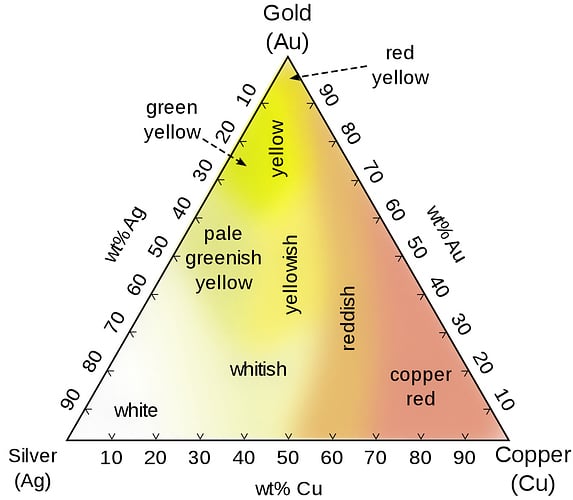

So say I wanna mix these 58.5 % + 20.75 % + 20.75 %…

-

Can I then reach the temp of the metal with highest flow temp, throw all my metals in, and then take down the temp to correct casting temp for 14 karat? Does the metals have the properties of alloyed 14 karat metal in molten form? or

-

Do I have to cast the metals at temps for 24 karat gold, and get the metal to solidify on ingot or charcoal, and then recast again with my new 14 karat alloyed metal?

Best regard William