I am Zakaria from Asia. I am pleased to join you. I pour 21 karat gold and my knowledge is little in the casting process. I have a vacuum at a speed of 45 cubic meters per hour, and my investment is cracking and collapsing. Is this because of the big vacuum yoke or something else?

Hello Zakaria and welcome to Orchid,

According to my research, one Cubic meter per hour is 0.59 cfm, which is the measure we use in the USA. Most vacuum pumps in casting setups I am familiar with are 3-6 cfm. If your figures are right, your pump is at 26 cfm, and that does sound like too much. However, I suspect that your figures could be off by a factor of ten and that your pump is actually producing 2.65 cfm, which would be about right. Maybe someone who does vacuum casting (I don’t) can tell you why the investment might be breaking up. -royjohn

Thank you for your reply, dear brother. Would you advise me to change the vacuum to half the speed that I have?

Yes my vacuum 26cfm

I’d check those number Zakaria, because that is a very big machine I’d say

750 litres a minute…

The question is how much vacuum it pulls.

If it is the amount of vacuum it can be regulated by pressure/vacuum switches.

If it pulls to fast a vacuum a restriction valve would take care of that.

But it may have with the compatibility of your wax and investment.

And of course a burnout cycle as recommended by the investment producer.

Regards Per-Ove

Excessive speed can make investment collapse?

My question would be where you got a pump with that kind of capacity. The typical vacuum pump used for jewelry casting in the US, as I said, pulls 3-6 cfm or up to a max of 10.2 cubic meters per hour. What you have, if your numbers are right, is a specialized vacuum pump made for some other function. I’m not sure how you would throttle something like that down to a typical 3-4cfm. I’m not an expert on vacuum casting, but I’d guess that too much vacuum could pull your investment apart. Maybe some expert will comment. In my area a used vacuum pump would cost about $100 to $200 and it might be well to get rid of what you have and get something that is more fitted to the task. -royjohn

I do concur Royjohn.

This pump is way over the top.

I was just pointing to easy adaptable ways to reduce speed of vacuum buildup.

A small tank and a vacuum switch can adjust vacuum.

But it will probably cost more than getting a new pump.

The OP is in another thread related to this, but I fail to understand his process completely.

If it wad me it would move this discussion to that thread.

Regards Per-Ove

Edit typing error.

Thank you everyone for interacting with me

I see that Zakaria.

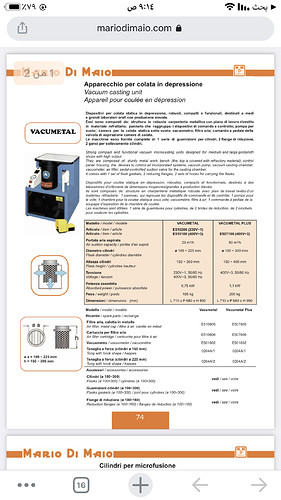

The size of the vacuum pump of these machines are mainly to vacuumate fast

so you don’t have to wait too long between

each casting.

This is production machines.

But as stated previously lets continue this in your other thread.

I believe that explains your problem much better, I do not think vacuum is your problem.

Regards Per-Ove