Hello! I’m struggling to mold a couple of CAD ring patterns I designed that have been successfully cast by shapeways. I imagine they’re printing the design in wax rather than molding a printed part of another substance, and then casting the wax directly. When I mold the master (a bronze cast of my design from shapeways) I have horrible issues getting the wax out without it breaking, as the silicone is in-between all these tiny details that shred the wax as I try to take it out.

I’ve seen equally detailed rings, if not more detailed, be lost-wax cast, and molded, so I’m struggling to believe this pattern is “too complex” to mold. I’m also curious if there’s a best way to cut the silicone in order to get the most optimal injection, as sometimes the mold is mashed due to my removal of the master. (I’m on mold number 3 right now and about to trash it, and I want to stop wasting money.)

I’m using pink wax, the Fuser500 wax injector, and poured silicone molding compound. I’m attaching pictures of the model I’m trying to mold.

Hi,

can you post pics of how you are cutting open your molds?

generally speaking, if the ring/ master was cast from a printed model, there would be less shrinkage than if the master was then molded, a wax shot, and then that wax cast…

my brain is thinking…perhaps…

carefully, safely

cut thru the mold vertically, along the flat side of the ring to open up the mold…your master will be embedded in the rubber…(and no parting lines on the band to clean up/ mess up your pattern)

cut around the interior diameter of the finger hole, in order to release the rubber in the cutouts…this would eventually leave the master/ the wax sitting around a core of rubber that you would eventually pull the master/ the wax off of…

then make release cuts perpendicular/ radially(?) around the outside diameter of the master so that you can fold/ bend back the rubber…the rubber will pull out of the cutouts while the master/ the wax is supported by the core…

hopefully it will not break when you pull it off the rubber core…?

…how thick is the ring…?

julie

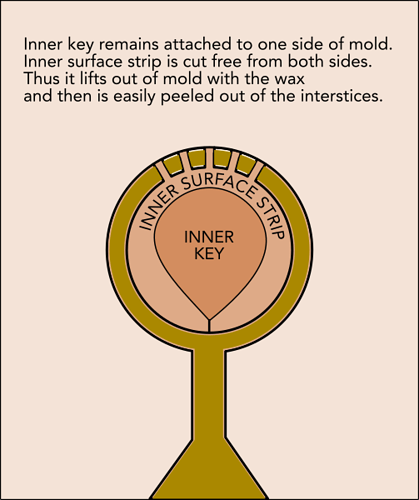

I suggest cutting an inner key which will allow an inside strip to be removed from the mold with the wax and then easily peeled out of the interstices.

2 Likes

A lot of folks think making molds and injecting waxes is easy and sometimes it is. This ring is especially difficult though, which you’re finding out with the little bits of rubber getting stuck in those tiny holes. You have a mixture of wide flat areas, with numerous tiny holes and lots of right angles, which when combined makes for a challenging mold to make and to get successful injected waxes.

I’ve made hundreds of rubber molds in my career and still don’t think that I’m great at it. Just good to pretty good. As Elliot_Nesterman says there are many tricks, like inner keys and removable mold sections.

I don’t have any advice for you, except to suggest sending your ring out to a professional casting and moldmaking company and have a professional mold maker make your rubber mold. It probably won’t cost a lot. Then you can see what they did and you’ll have something to replicate for future objects. Unfortunately, I don’t think there are any good videos or books describing how to cut apart complex rubber molds. That’s why I’m suggesting this idea.

Good luck! I feel your pain!!

Jeff

1 Like

Here is a different idea. How about making a master out o sheet metal. You can saw out the hole areas, Have a blank for pressing out blanks made. Actually cheaper and in some ways cheaper.

2 Likes

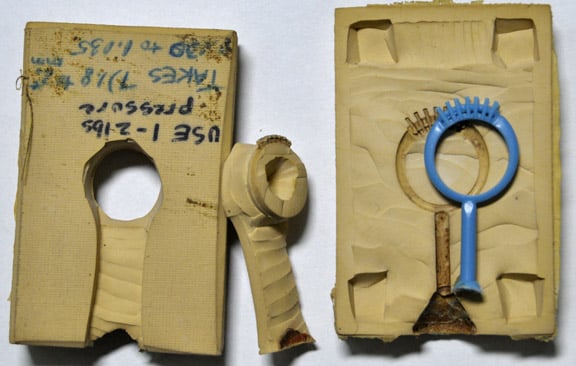

All those little holes usually won’t be a problem if you cut a plug. I learned this technique at a seminar put on by Romanoff. It changed my life. I have shown this technique to other jewelers when I visited. They immediately start cutting plugs in their molds. From time to time I will cut a plug in a mold I made years ago before I knew the technique. This is similar to the way Elliot showed. The wax in the picture pulls right out with all of the holes open if you use the right pressure on the injector. If anyone is interested, I will do a complete write up on how to do it.

Dave

2 Likes

Hi,

ah yes, i failed to mention the cross cuts…hmmm…

julie

Dave, this is great info! Thanks for sharing.

One thing that I was thinking about the original post is that they’re using liquid rubber. I think I’ve tried all of the liquid rubbers at some point (at least that Castaldo makes). I’ve found that while liquid mold rubbers offer numerous positive qualities none of them are as tough and strong as old school vulcanized rubber like you show here.

At this point I’ve switched to Castaldo’s silicone sheet vulcanized rubber because they don’t shrink as much. Those rubbers are stronger, but still not as strong as traditional vulcanized rubber.

Do you have experience or thoughts about the pluses and merits of different mold rubbers for complex molds?

I think that cutting open molds (especially when you can’t see what’s inside) is an art form in itself. Thanks again for sharing this!!

Jeff

Jeff

I have used liquid rubbers in the past but only do now when the model won’t take the heat. It is not as tough. Molds I made with it deteriorated in a few years. I have over 6000 rubber molds, most still usable. I am still using molds I made 50 years ago. A lot of the older ones don’t have plugs, so if it is a difficult one, I go in and cut a plug. A plug can be cut in a mold made with the liquid. This is not as strong, but the plug relieves the extreme stress of removing a wax with deep insides.

I have used both Castaldo yellow and white label. Now I usually use white label. Cutting plugs when necessary allows the wax to pull without needing the extra stretch of yellow. Plugs are especially helpful on models with deep insides.

Cut lots of deep vents. Powder first with talc. The talc helps keep the vents open. Then use a spray of mold release very sparingly. Talc is not usually needed after this. A guy that used to demonstrate mold cutting at the jewelry shows showed me a venting technique to vent to the outside flat part of the mold. Take an ordinary straight pin. Tap it on the point to make a very small hook. Shove this through the mold to the outside. Then pull back out. The hook will tear the hole and keep it slightly open for air.

As to not seeing inside the mold. In the past I have drawn an ink line on the difficult model where I wanted to cut. When the rubber vulcanizes, the ink line is transfered to the inside rubber. Cut on the line. I don’t remember what kind of ink I used.

Dave

1 Like

Driving a bent pin into a mold for a vent. What a great idea!

Thanks for sharing Dave!

Jeff

1 Like