Hi Julie,

I’ll be honest, I don’t pay close attention to the water temperature. I bring water to a boil, let it sit for a minute or so, pour it into a Pyrex container, put in the Jett Set and go from there. The instructions say 160 F to 170 F is the proper temperature.

Those containers of Jett Set are huge and they last for way too long! I have learned that it does have a shelf life. At some point after sitting unused for years it doesn’t work as well as as it did when it was new (even if the balls have never been melted before.)

After getting frustrated I’ve bought new Jett Sett and it works like it’s supposed to again.

Jeff

I don’t know if this is a no-no but I use (the finest) silicone polishing wheel sometimes and it seems to work fine.

2 Likes

Hi,

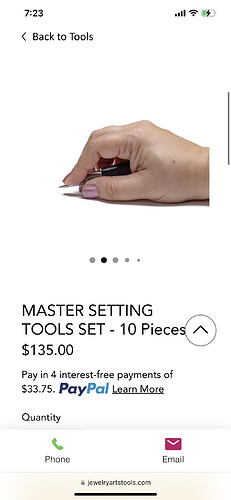

here is an interesting set if setting/ burnishing tools…there are 2 sets…same except that one just has larger handles

julie

1 Like

Thanks for all this information and the encouragement!!! Full dteam ahead!

SueS11184,

Whatever works is the right way to go!

I’m guessing that you’re talking about Shofu silicone polishing wheels or similar.

These are awesome and I use them as well, but I strive to not have them touch stones, only metal. There’s a zillion variables, the biggest being how hard is the stone? A glancing pass on a hard stone may not do anything. Where with a pearl or turquoise, you’ll probably grind a groove in it, even with a fine Shofu wheel.

The advantage of silicone and pumice is that it will grind away jewelry metals, but not damage many, if not most stones.

Again, like you, I use Shofu (or similar) fine rubber polishing wheels next to stones all of the time, but I’m super careful. With the silicone/pumice wheels I don’t have to be as careful.

Thanks!

Jeff

2 Likes

Hi Jeff,

I love Shofu mounted wheels especially because the are mounted and there are no mandrel screws sticking out to potentially, accidentally come into contact with the piece…!

julie

3 Likes

Thanks Jeff. The ones I use are the “Eve” line, from Rio. I use the finest one. I use gentle pressure, generally in a downwards motion (stone down to bezel), and it doesn’t take much, and barely touches the stone. When I discovered this it made a big difference to the finish when things got a tiny bit ragged. I don’t know anything about pumice, I will have to look into that. Cheerio

1 Like

That’s great! I just looked up EVE polishing wheels at Rio Grande. They use silicon carbide as their abrasive. Silicon carbide will definitely definitely damage many stones. But like you know, you just have to be careful.

Polish on!!

Thanks, Jeff

1 Like

Are the ones you mentioned less harmful? I haven’t noticed any damage, but I am pretty careful.

You mean harmful to the stones, not harmful to you right? All those rubberized abrasive/polishing wheels create dust that is bad to breathe.

They do different things. Silicone/pumice wheels grind out dents in bezels and prongs without damaging most stones, but they don’t polish at all. They’re fine grinding wheels that can “prefinish” before polishing. The coarser EVE wheels can grind out small dents & divets and the finer ones can polish. (like the Shofu wheels).

There so many different flex shaft and micro motor abrasives out there! It’s very confusing to know what they all do. Especially since many do similar, if not the same things, with different names and brands.

I just did a bit more digging in the Rio Grande website and see that most of the EVE wheels are rubber and various grits of silicon carbide (grinding and/or polishing), but they do make EVE rubber and pumice wheels too. Try them out some time. See how they compare to the silicon carbide abrasives.

Cheers!

Jeff

Thanks. Yes, harmful to stones. I do wear a mask (mostly!). I wish there was a video somewhere that really thoroughly showed all the various ways to polish. It would have to be a long one! I do my best, with various techniques, but sometimes I have polish-envy when I see things that are truly a mirror shine.

1 Like

Hi,

so…the general concept is to use progressively finer and finer grits….

you start with a grit just abrasive enough to remove the scratches without imparting deeper ones than are already there…

each successively finer grit will remove the deeper scratches and replace them with finer scratches

until the grit is so fine that the scratches are so fine and you have a mirror finish

in terms of implements…by hand…or rotary…

files and burs (which are basically rotary files) are usually the coarser options

then moving on to emery paper and attachments that are basically rotary emery paper…

grinding stone can overlap the above in terms of grit

rubber/ silicone/ radial bristle wheels kinda overlap as well

buffs and polishing compounds kinda overlap as well

i consider graystar pre-polish to be around 800 grit…

some buffs are intrinsically more aggressive than others

its basically a grit thing, combined with a shape thing…ie: what shape do you need to access the area you are working on?…it could be a tiny escapement or needle file…a knife edge rubber wheel…thrumming/ polishing string…

grit…shape/ profile…

2 Likes

Hi,

oh…i forgot to mention…

unitized and 3M type (like green dish scrubbies) remove very little metal, and leave a matte/ fine scratch surface…

brass and steel hand brushes, and rotary brushes don’t really remove metal…they burnish and leave a matte/ fine scratch surface…

hand burnisher abd rotary burnisher attachments…burnish, compress the surface…

speaking of…you can kind of apply the same general concepts when thinking about tumbling media…

julie

2 Likes

Those look great - sadly they don’t seem to deliver to BC. That seems odd.