Does anyone know what the small chisel that this guy uses when setting the smaller stones? Can’t find it for the life of me.

10:46 in this video: https://youtu.be/IKk3w7yEKWI?si=uCFQ-Pv7YBIe7cIA

Or

11:16 in this video: https://youtu.be/x1KmZIMKsSg?si=rFO_2L9U2G7Fwpo0

Looks like a beading tool…Rob

Hi,

in the first video, he is using a beading tool…

he uses a round bur to cut the seat

at the four “corners” of the stone seats is metal

(i do not see him using a cylinder bur to remove metal between the stones)

(i do not see him bright cutting the edges, which “release” the beads from the surrounding metal, making them easier to “move”…)

a beading tool is used to push down and spread the metal to captivate the edge of the stone

sometimes there are two “shared” beads between two stones (closer in to where the girdles start to come together…

or the metal is “split” using a prong splitter first (the tool used in the second video) to create four beads instead of two shared bead between each stone…

you can make your own bead splitter…

beading tools are sold on sets, and individual replacements can be purchased when a size wears out…

julie

2 Likes

Hi,

i forgot to mention…in the first video, i think he is just using the beading tool to make and split two beads off the one little mass of metal…

julie

In the first video he is using a beading tool to push and round over the beads, but the metal must be split first, as in the second video. There’s not enough depth to the edge of beading tools to split the metal. They have only a shallow depression in the end.

Splitting the metal could be done with a flat graver

The chisel in the second video was certainly made by the jeweler.

Learning to harden and temper steel so one can make small tools to purpose is an important skill to develop.

In this video by Bobby White at 5:39 you can see how he splits the beads with a custom chisel set in a graver handle. The link will take you to the time.

3 Likes

I regularly use a much wider chisel that I ground to a very thin profile all of the time. It was a recycled chisel from a machinists shop.

I do have some small chisels like what he is using but I made mine from lengths of piano wire. I did not buy them. I got packs of piano wire from McMaster-Carr. I take out a length (12 inches) and cut it to about 3 inches, anneal the metal as it is some REALLY hard stuff. I grind the shape that I want, then give it a rough sharpening, then harden and temper the cutting edge. I then use my graver sharpener to get a really sharp edge.

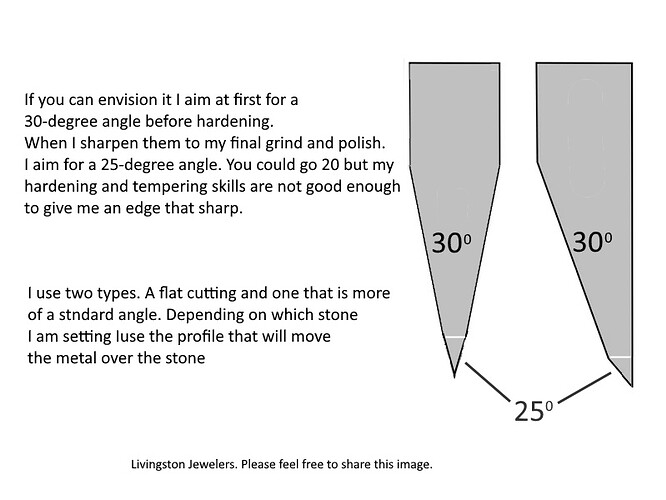

If you can envision it I aim at first for a 30-degree angle before hardening. When I sharpen them to my final grind and polish. I aim for a 25-degree angle. You could go 20 but my hardening and tempering skills are not good enough to give me an edge that sharp.

I occasionally need to sharpen them every so often but A quick touch-up on my graver sharpener is all that is needed.

4 Likes

Pretty picture. But nobody works on a lace tag (that is what that is called) while on a shoe.

I will have to watch this video tonight.

1 Like