I have a very old stock piece made by Novell Its a hand made braided band heavy 18k white gold. Novell has a free sizing but they might not be able to size it down 2 sizes, and would then charge me 20% of my orignal cost. I would love to try to size it down myself. Just not sure what I am dealing with. I cant seem to get a picture attached, but if anyone has any advise I can send image.

Noreen

Hi,

regarding attaching photos…

take a pic with your phone

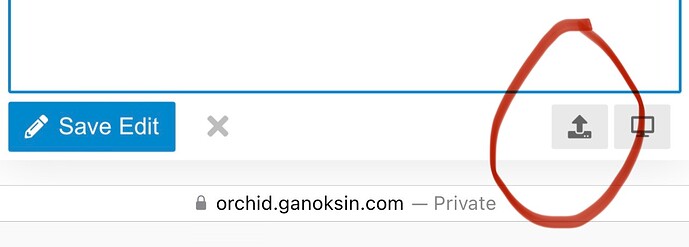

then at the bottom right of the posting window, there is an icin with an up-arrow…tap it and you will be allowed to upload photos by selecting them ftom your phone.

sometimes, when posting from my iphone, the posting window is expanded larger than my phone screen, thus “hiding part of the right side, as well as the bottom where the””save” button and icons reside…

i have to “pinch” my screen to get it to fit withing my ohone window…and it can be a bit finicky if the text is long…

julie

Can you locate the seam?..Rob

Thanks for the help with getting this photo in the message. I have not identified the seam, its a brand new/never sold or altered band. Im not sure if the body of the band is casting in one piece and the braid added? I need it to go down from a 9.75 to a 7.5

Would creating a liner be out of the question?

It looks to be fabricated. The problem you will have is matching the pattern repeat, especially on the larger braid. You might figure out how much of the ring needs to be removed to size it down and then use a caliper moving that distance around to find the best place for the patterns to line up. If none of that works, you might just think about adding another ring inside of it. Good luck…Rob

Hi Brennan,

Good idea! see…this is the kinda idea that never enters my mind…my dad woulda thought of it right away!

julie

I spoke to a buddy who owns a jewelry store that I used to work at and asked him what he thought. We both would approach this sizing the same way.

Here’s what my jewelry store buddy said:

“It could be sized down, but depending on where the cuts are, the braids may not match up. If they don’t, the place where it’s been sized will definitely be noticeable. If the braids are not soldered in now (and they may not be), they should be soldered in place before attempting to size it, otherwise it could be difficult for all of the pieces to stay in place while it’s being bent. Fun!!”

I’ve sized a zillion rings in my lifetime at various jewelry stores. There’s roughly 2.5 mm per size. That means you’ll take out a smidge over 5 mm to get it down to 7.5.

There’s generally more than one solution to a problem. While making an 18 kt white gold liner will work, I wouldn’t recommend it. It will be super expensive and assuming that you’ll be sweat soldering the liner in, you’ll be flooding your ring with gold solder, which will forever taint the purity of the ring.

Another thing to note. Because this 18 kt white ring is thick and that 18 kt white is a hard metal, bending this ring without marring it will be challenging. Just a heads on that point.

It’s definitely a challenging sizing, but is totally doable. If you’re not comfortable with taking it on or if you don’t want to send it back to the manufacturer for sizing, taking it to a jewelry store that specializes in jewelry repair would be a reasonable thing to consider.

It’s a beautiful ring!

Let us know what you decide.

Jeff

Make a new replica your size

What is circumference of existing? What is width? Based on photo I think a 5mm reduction in circumference will make a poorly proportioned final result.

Maybe, pay some one to scan into design software and proportionately shrink it?

I know that I said that a liner probably wasn’t something that I’d recommend, but that was with the idea of soldering in another 18 kt white gold ring inside this ring.

This morning I thought about Fretz spinner rings and how easy it would be to make an unsoldered silver inner liner to size this ring down a couple of sizes. There’s a bunch of YouTube videos explaining how the Fretz tool works. Here’s one from Rio Grande.

Fretz spinner rings usually have a wider inner band and a narrower outer band that spins around, but you could easily make this concept work for you without any solder on your wide 18 kt ring. If you make the inner band fit tightly, the outer band won’t spin around.

You can accomplish the same thing with large dapping punches if you don’t want to buy the Fretz tool. (I’ve done it both ways)

Whatever you do in sizing this ring you’re going to have to make some compromises. To me, the decision of what path to take comes down to what is going to be the most effective solution with the least amount of compromising (which includes cost).

In many ways the really big question is how long will 7.5 be the right size? Most people’s fingers change throughout their lives. This is a ring that you definitely don’t want to size repeatedly.

With an unsoldered silver liner, you’re not going to damage your vintage 18 kt white ring and you can remove the silver liner whenever you want. Theoretically, you won’t even see the silver. Compared to the cost of 18 kt, a silver liner will be way, way less.

Anyway, I wanted to throw this out as a possible solution. Maybe this was what Brennan was originally thinking and I just didn’t understand it? Let us know what you decide.

Jeff

This was what I was imagining. And for the record, if a better idea comes up I was also imaging that ![]()

I would put another ring on the inside if that is possible. The issue of covering the hallmarks and other stamping comes to mind.

Don