Hello!

Any advice on the soldering of 0.750 Ag pieces with joints previously tinned/soldered with Pb/Sn solder? Could be a problem with hard silver solder? Thanks!

You’ll have to remove all traces of the tin/lead solder before you can solder with hard silver solder. Many times a jewelry object is destroyed when repaired with tin/lead solder as removing every trace of it is impossible.

I wish there was an easy answer, but I don’t know one.

Sometimes when a broken jewelry object can’t be put back the way it was because of a tin/lead solder repair, you can reinvent it with cold connections. For instance, if someone tried soldering on broken ear post with tin/lead solder and you can’t remove all of the solder, sometimes you can drill a hole in the earring and turn it into a hanging earring with an ear wire.

Hope that helps a little bit. Best of luck!

Jeff

Hi,

if the repair is not directly on an area that may have tin/ lead, then perhaps welder or laser…?

if you do not have, perhaps a nearby shop does?

julie

Thank you both for that! Unfortunately, the problem is a little more complicate… it’s a 2 parts object (one fill inside the other like pipes) but the “connecting” side is missing.

Just to have an idea…

yikes! that’s a mess…there’s a ton of excess tin/lead solder on it…I don’t have any good ideas on how to completely get rid of it…heating and wiping it off as completely as possible would be a start but getting rid of all of it will be nearly impossible…any amount of residual lead will turn silver into a gray powder when heated dull red… you could try melting and wiping away as much solder as you can, mechanically removing more, then finally putting it into boiling vinegar or cold muriatic/hydrochloric acid… acid out of the bottle has to be diluted to 1/4 to 10% strength…HCl acid will dissolve tin and lead faster than silver, but using acid will also attack silver, only less slowly…it can also be removed electrolytically but that requires professional equipment.

the only simple option would be to clean off the excess lead/tin solder, and resolder using pure tin solder… the joint will be weak, and also visible…

Hmm, I have this stuff :)!

I must confess I didn’t think to remove the solder elecrolitically! I have a small issue: I need to find a knowledgeable person to recommend the best electrolyte/cathode/anode combination. It is easy to make a mess and very difficult to repair…

Checked with an XRF device, and the silver alloy originally contained a small amount of added lead (roughly 0.3-4%). Thanks for the idea!

Errata: not “added” but probably from the ore…

Most of us who are over 65 have a piece like this that some well meaning person, maybe a relative, tried to fix with low temperature lead solder. When asked to fix them, if they are broken, I turn them down for all the reasons described by others. Good luck with this project…Rob

If the goal is to bring this back to brand new. I don’t think it’s possible. I think it’s forever going to be altered. But you can probably fix it, make it whole again and not look too bad.

Personally, I would stay away from any acids or high tech electronic equipment to remove the excess tin/lead solder. But that’s just me. If you want to pursue that path, go for it.

Here’s what I would do.

From the picture I’m not sure what this object is? But from what I can see, I would first physically remove as much of the tin/lead solder as possible. For this task I prefer diamond burs as they don’t bounce around as much as metal burs. This is my favorite set of diamond burs. Treat them well and they will last a long time. (Other companies sell this same set. Rio Grande is just an example)

Rio Grande: Diamond Bur Set Item No. 345933

Then I would repair this with Stay Brite Low Temp Silver Solder. It’s the best and cleanest low temp repair solder.

Rio Grande: Stay-Brite Solder and Stay-Clean Flux Kit Item No. 503031

If necessary for strength I would sweat solder a silver band around the joint with Stay Brite solder.

Practice a bit with the Stay Brite solder on something else before you begin this repair. All low temp solders behave very differently from regular higher melting silver and gold solders. It takes a bit practice to learn to make it work without making a mess. (like what you’re seeing here with whoever fixed this the first time.)

One other thing to remember, Stay Brite solder will only melt and flow with the flux that comes in the kit. Sometimes you even need to add more flux as you’re heating it to get the solder to melt.

Don’t put this in the pickle! All you’ll do is contaminate your pickle. To clean it after soldering with Stay Brite put in an ultra sonic cleaner or soak it in hot water for few minutes to remove the excess flux.

Finally, if you do any filing on the tin/lead or Stay Brite solder, use an old file that you don’t care about as you’ll forever contaminate that file. Also, make sure there are no low temp solder chips or dust anywhere. Keep your workspaces clean.

This object is probably hollow, so that adds in other issues. But from the section that I can see, that’s how I would proceed.

Hope that helps!!

Jeff

Hi,

may i ask?…what is the object? a handle on a serving utensil or teapot? is it part of a matching set?

could you post a pic of the whole object?

is it sterling silver? pewter?

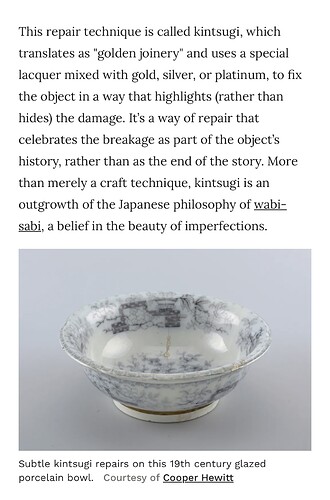

curious…perhaps you could consider a repair that cuts out the affected area and replaces it…something along the lines of kintsugi and wabi-sabi…perhaps a beautiful wood…

julie

I don’t think that it can be done electrolytically at home… different voltages and salts specific for each metal has to be used with just the right amount of current. That’s the principle… the practice is beyond the reach of the home jeweler, including me…and would have to be done by a specialist metal smith with the right kind of equipment…If you opt to use acid, be very careful… as mentioned, it does attack silver also, just less…too much old solder will take too long to dissolve while the silver gets attacked… .Jeff’s suggest for a repair makes more sense… if you can’t clean out all of the residual solder mechanically, then you might have to cut the section out and replace it with silver, rework it to match the ends… whatever it is… might be too much work to be worth it.

There are lead scavenging hand soaps which are marketed to shooting ranges and industries that use heavy metals. This might be a way to remove thin surface contaminations. Soap and a nail brush. At least one is available on Amazon, and various industrial supply houses.