Is it possible to use the Japanese style water stones to sharpen

gravers? I have yet to sharpen/use one, but am soon going to cut my

teeth. I want to bright cut big fat bezels. I know from my

woodworking experience they produced a beautiful mirror edge on

Japanese style laminated chisels. Must be a reason why Arkansas

style stones seems to benthe standard. Thanks.

Is it possible to use the Japanese style water stones to sharpen gravers?

It is possible, of course, but it would not be good for the stones.

Japanese stones are softer, i. e., they abrade more quickly, than

Arkansas stones. So the tips of the gravers will likely wear unhappy

grooves into Japanese stones in a short time.

FWIW, most of the setters I’ve known sharpen their gravers on white

hard Arkansas stones and polish the bright cut face on artificial

ruby stones, but black surgical Arkansas stones should do as well.

Elliot Nesterman

Hi Saboiam,

Yes you can, but no, you don’t want to.

Water stones are very soft. The very narrow widths of an engraver

will wear grooves into them in almost no time at all, which will

cause you all sorts of trouble with edge geometry, and things

getting out of flat. (why do you think the woodworkers get so

obsessive about the diamond flat plates to keep grinding the

waterstones flat?)

Arkansas stones are harder, and don’t wear as easily, so you’ll have

less trouble with wearing grooves into them. You still will put

grooves in, but it’ll take years instead of days.

Regards,

Brian

I use the Jura’s Swiss Ceragloss 25mm blue medium diamond polishing

wheel, then the Ceragloss yellow fine diamond polishing wheel if I

want a true mirror surface, especially for bright cutting. They’re

not cheap ($42 each), but they do last a very long time. When one

side has been depleted, just turn it over. The Ceragloss blue is

especially good for sharpening scribes and center punches.

Jeff Herman

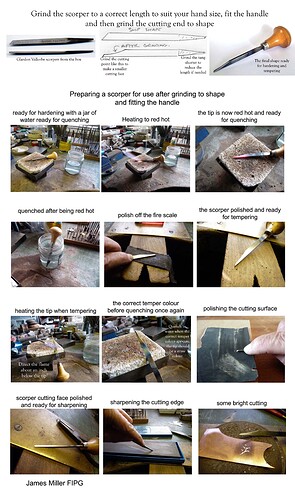

Saboian- Properly setting up, shaping and polishing a graver can

make your work so much easier. Just remember that the heel or the

bottom of your graver should be just as polished as the cutting edge.

No matter how sharp and polished your cutting edge is, the heel drags

along behind it. Like cutting with a scalpel and then dragging a

rusty nail behind it.

I just finished setting up and polishing and shaping 1/2 dozen

gravers for my next setting class. I start my students out with a 42

flat. I find that the blades when fresh from the factory have some

pretty deep grooves in them. For what they cost you’d think that

they’d come with a finer finish.

It takes me a longer time to get the heels perfectly polished out

than it does to attach them to the handles, shorten to my hand,

shape, polish and sharpen.

I use two sharpening blocks. One is two sided with a coarse side and

a finer side. I then go to an Arkansas stone and then crocus paper

taped down on a flat surface. I then punch the tip of the freshly

polished graver into my wooden bench pin to take any burr off the

cutting edge.

For polishing the heel I use successively finer emery then arkansas

stone then crocus paper. I do this after shaping and shortening and

before I start sharpening.

Have fun and make lots of jewelry.

Jo Haemer

timothywgreen.com

Jeffrey- Thanks for the info. Do you use these on a polishing lathe

or a flex shaft? -Jo Haemer

Hah. I figured there had to be a reason the stones bad not been

adopted for gravers. and I figured there had to be a reason for me

NOT being the genius to think of it.

Thanks all for your comments. like the ground hog, gotta get out of

the hole and see the sun at times!!!

Arkansas here I come!

I use Spyderco ceramic whet stones for sharpening my gravers in

medium and fine grits; All Products - Spyderco, Inc.

and I polish the cutting face of flat gravers using fine polishing

paper on a steel block. Here in the UK flat gravers are called

scorpers, I use carbon steel Glardon Vallorbe scorpers which I grind

to a suitable length to fit my hand size and shape the cutting point

to suit the job, then I re harden and temper the cutting end before

use. The attachment is a photo sheet that shows how I prepare my

scorpers/gravers.

James Miller FIPG

Hello Jo,

Do you use these on a polishing lathe or a flex shaft?

They’re flexshaft-size. I also use them to sharpen small drill bits.

Jeff Herman

Dear man, you are my hero! My fiancé, a bench jeweler for over 40 years, passed away 2 years ago. We had a great time building our business together while he tried to pour into me 40+ years of knowledge. It was a bit like trying to drink water from a fire hydrant. And there was still so much that I didn’t have time to learn.

He taught me how to use certain gravers (Scorpers, huh? I’m in the US). But I never learned how to sharpen them, or what to do when I received a new graver, cut but not sharpened. This sheet is so very helpful. Thank you so very much for freely sharing from your wealth of knowledge.

Gratefully, Robin