Can someone out there in Orchidland explain to me the fascination

with 18K white gold? I love the white metals and I understand the

wonderful karat differences between other colors of gold but why

would a customer buy a costlier 18K white gold object that looks the

same as a 14K white gold object? What are the selling points?

Orchid Rules! Karla in S. California

I do find a difference in the color from the 14kw to 18kw, even more

so with pladium white( gray in tone).The standard 18k white I have

used is whiter with less yellow tones .I generally use a low nickel

14kw from DH Fell& co,the non pladium white I have tried has better

color but it is very trickey to cast.For me it tends to come up

with a fine poristy problem that I do not have with the others

alloys I use. Any feed back on that problem would be appreciated.

I prefer to go with the natural color of the alloy than having to do

a rhodium finish.

Hi Karla, You ask why would someone want 18kt white gold? Well one of

the major reasons 18kt white that is alloyed white palladium is used

is that it is a wonderful material to set stones in. It behaves much

like platinum at a fraction of the cost. Another reason one might

choose 18kt white is that it is sort of greyish brown in color rather

than the purew white of platinum. For certain married metal pieces it

gives an interesting color contrast. I have also used it for men’s

jewelry where I find the color is suitable. If you are looking for an

inexpensive durable white precious metal, then you are right. 14kt

white gold is great unless of course your client is allergic to the

nickel in most white. However in the end nothing beats platinum as a

white jewelers metal. etienne@etienne.com

Karla, As to the selling points of 18kt white gold; just the fact

that the gold content is 75% as opposed to 58.5% substantiates the

higher price over a similar item in 14kt. Aesthetically the 18kt

palladium white gold alloys are fantastic metals to work with, there

is no comparison, between the two karats aside from the color. And,

in my opinion the superiority of the 18kt metal’s performance

outweighs the slight difference in color. I have not yet had any of

the galleries which represent my work comment that their clientele

didn’t find 18kt white gold to be white enough. As with most

precious commodities, purer is better!

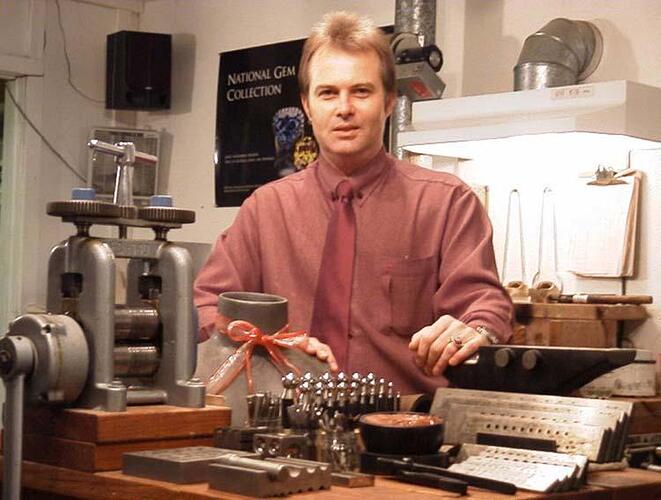

Michael David Sturlin, jewelry artist @Michael_David_Sturli

https://www.ganoksin.com/orchid/sturlin.htm

Michael Sturlin Studio, Scottsdale Arizona USA

Karla, I think that some people just like to know that the alloy

contains 75% pure gold versus the lower gold content of 14K. To my

eye, 14K white looks whiter than 18K white. Joel

Joel Schwalb

@Joel_Schwalb

www.schwalbstudio.com

color but it is very trickey to cast.For me it tends to come

up with a fine poristy problem that I do not have with the others

alloys I use. Any feed back on that problem would be appreciated.

Hi Michael: Porosity can be caused by a number of things. Improper

sprueing and casting with the mold at the wrong temperature are the

most common culprits. I try to “think like the molten metal” when

sprueing. It doesn’t like bottle-necks and doesn’t like to go around

sharp corners. Large masses of metal shrink as they cool, and need

some more molten metal to draw from (dead-sprue) or they’ll pull

themselves apart at the surface. When possible, have metal flow from

thick to thin. I prefer vacuum assist, with a mold temperature of

about 850-900 F. depending on the thickness of the article (thinner

needs slightly hotter). For centrifugal, and especially with silver,

I’ll cast as low as 700 F. But in the case of palladium alloys, I

would suspect another factor. The crystobolite based investments

(standard investments) can negatively affect palladium. Invest with

a plaster designed for platinum casting. The traditional

non-crystobolite investment used in platinum casting uses a catalyst,

which is mixed with the water used in investing. This type of

investment takes 8-12 hours to set up, and should be used with paper

towels instead of the rubber base (this is a real pain to set up) as

it needs to have the water “wicked-off”. PM West has a new quick

setting non-crystobolite investment they sell through RioGrande that

is a lot easier to use. It behaves like standard investment. Also,

you shouldn’t melt your palladium alloy in an “electro-melt” or with

acetylene fuel. It would be preferred to melt in a ceramic crucible

(for vacuum assist) or directly in the crucible of your centrifugal

casting machine using propane or natural gas. This avoids

contaminating the palladium with too much carbon. I don’t know what

the situation is pertinent to induction casting. (Daniel Grandi

would know about it, I’d wager).

David L. Huffman

If we’re talking about nickel white golds, then 18k NICKEL white is

much harder than 14k NICKEL white. It doesn’t seem like it would be

true, but it is.

Andy Cooperman

Hi David and Thank you for your response,

I also cast at 900 F and use vacuum assist castings,( by the way the

new and approved wax web from rio is working great) .I think my

problem is the certain alloy, This is a low nickel and no palladium

alloy in 18k white,the color is nice, easy to set not as hard as the

nickel white.

here is a link to dhf on this gold alloy

http://dhfco.com/pages/gold_karat.html#plus6b

Over heating seems to be the biggest possibility, i have called DHF

and it does seem to be a more problematic alloy , i noticed they are

calling the 18k white plus a new alloy I may not have tried this

particular one but I do use the other plus alloys with great

results.Has any one else been using these specific alloys including

the 18k white plus.I really want to do more 18k white casting but

this fine porosity problem has kept me from that direction.

Michael Devlin