I have been going over the document i made of all the discussions on

which blades are best. I must admit I am still somewhat comfused but

I did order some 3/0 tonight. I have 2 questinons.

Even tho I do work with about 18 - 22 gauge nickel, I do pierce.

Does piercing with nickel change the size of fine blades that one

would use with silver, brass or copper?

Also, I have some blades that somehow I failed to label and I forget

what size they are. How can I figure this out? My eyes are not sharp

enough to count teeth… sigh thx brenda

Hello Brenda,

Piercing or just cutting out a shape - you need the same size blade.

It’s related to the thickness of the sheet. Although you can use a

blade with more teeth… it will just take a little longer.

If you can’t count the teeth on the mystery blades with the naked

eye, and you don’t have an optivisor, get a pair of cheapie reading

glasses that will magnify enough to allow you to see and count.

Hope this helps and keep on sawing,

Judy in Kansas, where temps have risen into the 90s during the day

and the gusty winds make it seem even hotter. Happy Solstice

everyone. Summer is officially here.

In the future do what I do with my solders mark them with different

colors of magic markers for each size. even without good eyes we can

see different colors. Helps me. hope it helps you…

Hello Brenda

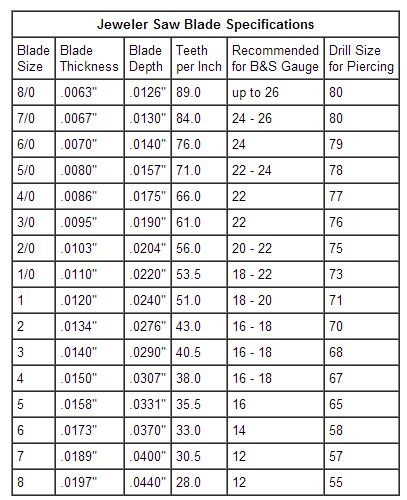

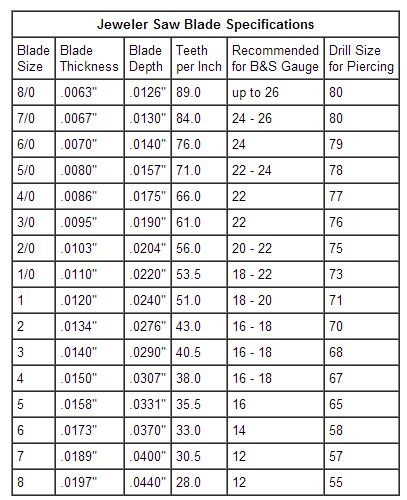

This chart (below) may help you figure it out. Its a standard

textbook reference chart (public domain) that I had on a cork board

with a sheet protector as a cover. It’s particularly useful if you

want to choose the correct drill for beginning a piercing

The main thing to remember in assessing which blade size is correct

for your work is : the higher the number of teeth (beginning with

10/0) the lighter the gauge- that should help clarify the ’ blade

rule’ for you. Many blades serve a range of gauges too, for example,

anything from a 3/0-1/0 is fine for 22 gauge dead soft material, the

harder the metal the less teeth you want. in my estimation that’s the

confusing factor in blade selection! more teeth means a thinner,

perhaps softer metal. I know some metalsmiths that use all gauges of

silver and gold in different karats, but generally soft temper and

keep a 3/0 blade loaded in the frame, ready to tighten down all the

way.

Nickel is a bit harder than silver and copper so keeping that in

mind you may go a gauge higher (i. e.- if the sheet is 18-22, go with

a #2 blade) and remember to lubricate it well with a bur lube or

beeswax- the stick types, whatever the brand, tend to work better

than the liquids for saw blades. Also your strokes should rely on the

angles you use rather than pressure- It’s pressure (and binding) that

snap blades- also check the blade’s hold downs periodically. I like

the lightweight Swiss saw frames because of the mechanism that locks

the blades in place and seems to cut way down on breakage, but still

keep a few various throat sizes of German type clamp lock frames on

hand for very large and very small work pieces. The only drawback to

the German frames is the clamps need occasional roughing to grab the

smooth ends of the blades particularly if they wear on the inside of

the square clamps- or there are kits from many suppliers for

replacing them entirely. You can take a jeweller’s loupe and count

the teeth in an inch on the blades and take a piece of tape to wrap

the end to mark the sizes (I’m hoping they are still bundled!).Keep

your blades protected from humidity so rust doesn’t set in. A sheet

of waxed paper around them is good if not apiece of parchment, or

cellophane tube as for packaging incense (they are quite inexpensive

and cellophane helps keep moisture out…

Hope this helps,

rer

Sawing nickel silver, brass, copper or silver in the same ga.

doesn’t require any differnce in sawblade size. You may possibly

want to use one size bigger with NS because it’s tougher, and the

bigger blade will allowyou to saw faster if you push harder.

I don’t have it memorized, but sawblade sizes are also accounted for

by their thickness, and there are charts for this wherever other

jewelry charts are forund (^8. You’d need an accurate caliper,

because the differences are as little as .001", with some variation

that large between different brands of a given size.

Dar

Put a saw blade on a copy machine next to a ruler and make a copy at

300%. Then it’s easy to count teeth/inch.

Jamie King,

Put a saw blade on a copy machine next to a ruler and make a copy

at 300%. Then it's easy to count teeth/inch.

Now that’s what I’m talkin’ about! Thinking out of the box for sure.

Thanks Jamie.

Judy in Kansas, who has been pulling a huge crop of weeds in the

strawberry bed. WHERE did they all come frome

Put a saw blade on a copy machine next to a ruler and make a copy

at 300%. Then it's easy to count teeth/inch. Now that's what I'm

talkin' about! Thinking out of the box for sure.

nside the box for a sec (because it’s easier sometimes) : You could

just put on a magnifying visor. I like using calipers to measure

thickness because it’s faster than counting teeth. I only count

teeth when I’m flossing, and then I’m really counting the spaces.

Usually, there’s the same number…

Except for sawing pancake dies, where it is definitely required to

know what size I have, I am not too particular. I use big ones on

thick stuff, medium ones on medium stuff, and small ones on thin

stuff. I have a couple of trays of strays that are away from the die

sawing area, andit’s a serious ‘mixed sizes’ situation.

sheltech.net