I’ve made a texture to imprint onto silver clay. I made this with a steel backed photo polymer plate. When I roll silver clay onto the plate, it sticks to the plate. Anyone have a solution. I’ve used “cool slip” from cool tools but the clay still sticks… help?

Ive never tried this but from my baking days would some sort of oil work on the plate and burn off when fired? Idk im just guessing here.

Aaron

Go to a wood working store. Even Home Depot might have it. Get a silicone spray. It’s used on wood working machines to make a slippery surface so the wood won’t catch. Different art mediums have lots of interchangeable products.

Aggie

What depth is your photopolymer plate? How detailed is your design? Did you do a test pull using something else like polymer clay?

I would caution you to limit or avoid oils and silicone spray - they can alter the metal clay - sometimes into a sticky mess. With a clean dry photopolymer plate and new metal clay, you should be able to gently roll and then remove the clay with nothing left behind.

It’s been quite awhile since I made photopolymer plates for use with my metal clay pieces, but I did have a thought that might help you solve the mystery of why your metal clay does not release well from your plate. When making a photopolymer plate, the plate has to be cured completely and scrubbed under water before it can be used. If the plate is not thoroughly cured, it can remain a little sticky, which will make it difficult, if not impossible to remove metal clay from the plate. I don’t know if this is the problem with the plate that you made, but, if it is, you might consider making a fresh plate and then making certain that you cure it sufficiently, and then scrub it sufficiently. And just a little thought here. . . you might try to use a very light dusting of your plate with talcum or other fine powder. I know that this sounds counter intuitive, but it might make it possible for you to use the plate that, so far, has not been ‘behaving’ itself.

Haven’t heard back from you in the posted questions… Please answer those few questions and take some photos of what you have used in the process - the plate, the clay, was it new clay, how did you make the plate? I’ve taught photopolymer plate making for 10 years - I can tell you there’s a zillion different little things that can go wrong. I am curious about your issue and hope we can help you.

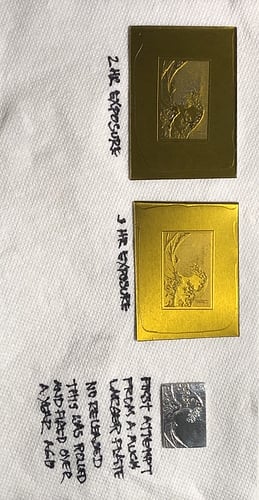

Sorry, I’ve been distracted with some other issues lately. When I first tried using steel backed polymer plates and rolling silver clay to pick up the image it worked without a hitch… no sticking/ perfect detail in the clay. The first clay I used was .999 Art Clay Silver. I didn’t, use any release, I cured the plates for the exact amount of time, and with the same light I had used to expose it… all was good. I used different brands and types of clay (sterling, bronze, copper. No problems) then I stepped away from the process for a little while and when I came back, the problem began. I’m not aware of having changed anything, but I’m guessing that I did in fact change something. Just not sure what that might have been. I recently made some new plates and will try it again with fresh clay. Your suggestion about the talcum sounds great, actually… makes complete sense. I assume it would require a very light dusting. I’ve yet to try the talcum idea as it’s now a little difficult to get pure talcum powder. I ordered some online and will get a chance to try it all again.

You said something in a sequence that I don’t do that I’d like to clarify; “When making a photopolymer plate, the plate has to be cured completely and scrubbed under water before it can be used.”

I expose it, then immediately scrub it out in a bowl of hot water. I then rinse it, blot much of the water off and the blow dry it followed by curing under the same light I used to expose it for the same amount of time (or longer), then after a day or so… roll some clay onto it. I have not rinsed it again after curing. Should I be doing that? The use of talcum powder actually sounds like a very good idea BTW. I can send some photos, if I can figure out how to attach them:-). Either way, thank you so much!

My instinct would be to use a fine dusting of talc.

- The plate must be cured completely, otherwise it will retain a sticky surface. Follow all the directions religiously from the manufacturer of the photopolymer plate.

- If your metal clay is too sticky (too much water in it), try letting it air dry just a little bit.

- Try the talcum powder as I suggested, if the clay is sticking to the plate. This needs to be a veryyyyyy light coating. You don’t want to contaminate the metal clay.

- Check back with Gwen Bernecker, as I know that she probably has handle on all the other variables that are involved with the use of ppp’s.

Hello community! I’m a little embarrassed about this but the problem with clay sticking to photopolymer plates had noting whatsoever to do with the Plates or how I made them… it was the clay. Much of it had gotten old, some of it had been reconstituted incorrectly… point being (as I’d mentioned earlier) that at first it all went perfectly. Rolled the clay onto the finished plate then lifted it off and then it began sticking. Got brand new clay and it worked perfectly, no release needed at all. Anyway, thank you sooo much,

Stan

silicone spray lubricants are also at autopart stores.

Thanks Linda❤️ Nice to see you on here! Time is just flyin’ by…