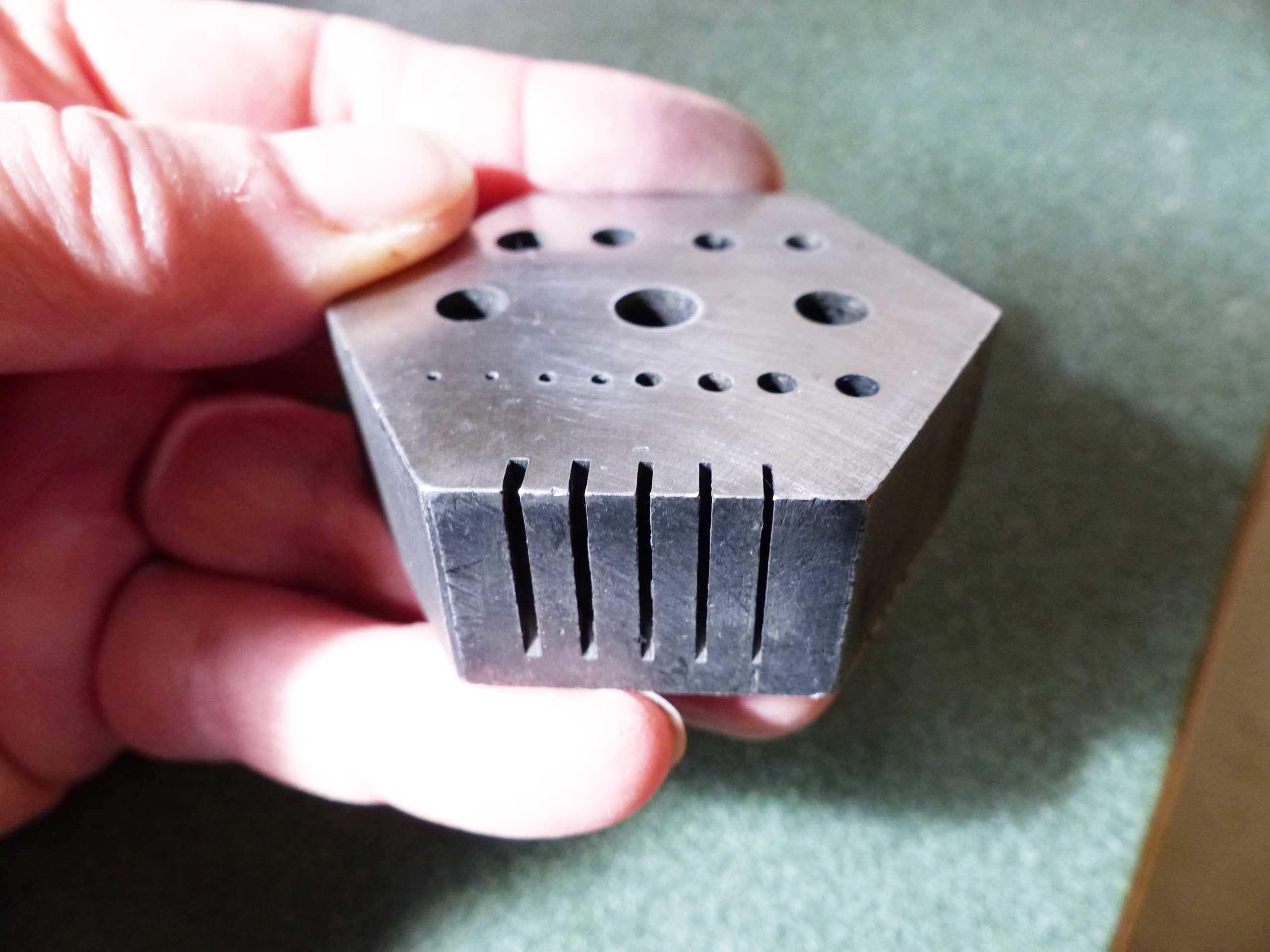

Does anyon know what these slots are called and how they are used? Oops. Looks like I asked this same question in March 2014. There’s nothing in Opp, nothing in Complete Metalsmith,

Does anyon know what these slots are called and how they are used? Oops. Looks like I asked this same question in March 2014. There’s nothing in Opp, nothing in Complete Metalsmith,

You are looking at it the wrong way. Instead of seeing the slots, look at the metal between them. They are cooling fins.

O.K. seriously… This has come up before (I don’t know how to link to the entry - see Noralie Katsu’s “Using Riveting Block” post on May 10, 2010). There was no answer to this question.

Someone asked at Otto Frei and they had no answer either. It may have been me, or it may have been someone on Orchid, I have no idea which - my Senior memory strikes again. My partly reliable, partly unreliable memory says Otto frei said the blocks are a watchmaker’s tool, so the slots may have some use in watchmaking.

Questions that could be asked - has anyone on Orchid ever used the slots? If yes, to do what?

Until a real use comes up, cooling fins is as good an answer as anything.

Playfully,

Neil A

I can’t help with an answer either, but would like to know too. I recently purchased a vintage K&S block like this one and couldn’t even guess what the slots are for.

Sharon in Iowa

I don’t know for sure, but I would use it to drive longer pins out of whatever they were holding together. Different sized slots for different diameter pins. Since this is just a guess, I await the input from someone who knows the answer for sure…Rob

Further to my previous post, go this link. Apparently the slots allow you to head various sized wire into rivets.

Rob

Ted here,

Im going to annoy every one by disagreeing with all the posts.

I dont use this tool but if I had one the slots would be ideal for making sharp angled bends in different thickness strip to make for example the sides of say a 6 sided bezel out of 2 pieces bent using the slots to marks on the metal, tapped down with a hammer to 60 deg.

Or 2 rectangled pieces for the sides of a box lid bent down to 90 deg.

How else would you bend accurately at a mark with both sides flat?

think about it.

rivets however, are always made in a hole. so do the round holes in the top go right through?

they would need to so you could knock out the rivet from the underside once youve formed the head.

99% of my work is wrought so bending hammering forging minting metal is my forte.

I’d rather stick humorously with the cooling fins explanation, but it would be nice to get an answer. So far no cigar. Getting serious…

In reply to Rob’s citation of the waymil site:

“Small hexagon steel block has 15 holes in different diameters along with 5 slots along one edge for forming wire rivets.”

But this doesn’t explain how the slots are to be used.

Maybe their phrasing is misleading, so let’s rephrase their description:

“Small hexagon steel block for forming wire rivets has 15 holes in different diameters along with 5 slots along one edge.”

I think that is really what they intended to say, just physically describe the object. There is no answer to the slots question.

I was taught that rivets are made by heating one end of a wire to form a slight ball, cutting to length, inserting the rivet in the pieces to be joined, hammering the other end, finishing each end. This process works for me just like that. So how might the slots enter into this?

In reply to Ted’s post, the slots are not deep and they are cut into the block at a 45 degree angle, not down the whole side. On my block the top of the slots measure 5mm, the face of the slots measure 5mm so the hypotenuses are about 7mm. What are you going to bend in a triangular cutout of 5x5x7 millimeters? Whatever it is, that’s all you can do with them. The slots have different gaps but they are all of the same dimensions otherwise.

Seriously,

Neil A

I agree, if I were making a rivet, which I never do, I would round the end of a piece of wire with a torch, put the wire into a drilled hole not much bigger than the diameter of the wire and then pound the rounded end to create one end of the rivet. I don’t see how you could do this with the slots. I am just passing on the description that I found on the internet to keep this conversation going, as I am interested in an answer that makes sense. This still begs the question, “what are the slots for?”…Rob

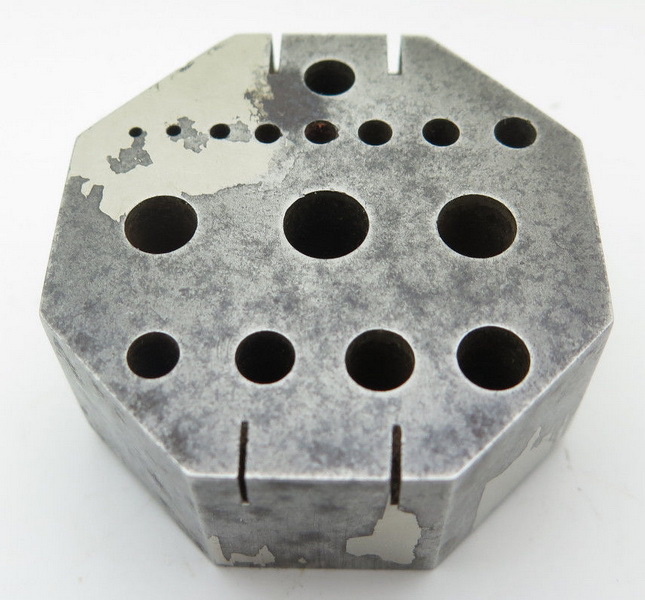

Here’s a picture of the block I own. It is similar to Betsy’s, but quite different too. If both blocks serve the same purpose and one could buy a block like Betsy’s or one like mine and do the same work, does the size of the slots matter? Those on my block are only 5mm.

Perhaps this is a crazy question, but does anyone use these blocks for riveting? Or might they be the pet rocks of the jewelry tools world, something people buy because they look cool?

Neil A

I believe they’re used in the watchmaking field. Perhaps the slots are used for adjusting gears that are out of whack.

Below are pics of my little K&D model (1-5/8" across 3/4" high). My slots do not take the corner of a piece of metal, rather you can slide a piece of metal to any point along its edge. The slots are cut straight in at an angle. Makes it even more puzzling…

<img src="/uploads/db0786/original/2X/2/20222e633ecc0c8134ea57dc6cc7a6130462f20d.jpg" width=272" height=“250”>

The back reminds me of a drawplate… Maybe held in a vise it could be used in the same way, but that still doesn’t account for the slots…

Sharon in Iowa

I think it was just an easy feature to put in so they did. Adds value and

years of entertainment of people wondering. It might relate to gauge sizes.

It would be very helpful making right angles on small pieces of flat stock.

We use ours at the watch bench to push out band pins. I actually thought it

was a watch tool. That’s the only place I ever saw them before was at a

watchmaker bench. I use it pretty often for that, not much for anything

else.

So if this is a watchmakers tool, how are the holes used for that application? Just curious… I am going to try it for removing pins. Seems like a better option than a tiny screwdriver.

The slots are used to hold small parts that have extensions (like shafts and pinions) that don’t exactly fit the holes) in place on the block while you work on them.

This is an interesting discussion.

I am sure that I should know this, from the time I spent at Bowman Technical School, but my focus was on stone setting and jewelry tepair, and I spent little time watching the clockmaking and watchmaking students at their benches.

I suspect that since this is a watchmaker’s anvil the slots probably had something to do with either gear, or balance wheel work.

I can certainly see the various size slots being used to gently hold a balance wheel, while turning a balance wheel screw in, or out, to correct the speed of that balance wheel.

This would explain why the slots are only near the top edge, and not slots continuing down the entire side, which they would do if they were designed for bending strip or sheet. A watch or clockmaker would only need to place a balance wheel partially in the slot that fit it, while using a screwdriver to turn the screw.

Of course, I am just making a wild guess. A classicly trained watch or clockmaker might be able to give a more educated answer.

My guess is that they’re for removing pins as well.

This is a must-see for anyone interesting in the watchmakers art. It’s both mesmerizing and humbling.

I feel like we defintely need bill.tokyo to weigh in here!

julie

Hmmm…I’ve rigged up notches/slots like that in a chunk of aluminum bar

stock to help open and close jump rings, but if that’s a purpose made

tool common to the watchmaking trade I can only imagine what it’s really

intended for.