My customer wants a wide (1.5 cms) ring, with metal 1.2 cms thick. The inner diameter is 1.67cms. I have made it using the usual formula but it is too small. I can’t find any formula in the archives to help me calculate the ideal inner circumference to use for a ring as wide or thick as this, so I can cut a ring blank. Could anyone help please?

Hi,

it seems to me that bending a 15mm x 12mm piece of stock into a ring with a 16.7mm diameter might be difficult…how are you bending?

perhaps you could use a 15mm thick piece of metal, and pierce the ring out of it…

or, carve it in wax and then have it cast…

if the inside diameter is 16.7mm, then the outside diameter would be 12.0 + 16.7 + 12.0

also, i am wondering…when you say the ring is “too small”, do you mean that it feels too small on the customers finger? or after using calculations the actual ring has a smaller diameter than planned?

sometimes wider/ thicker bands require a slightly larger size than is usual for the wearer

curious to hear your process!

julie

Thanks Julie … with the one I made that was too tight, I ordered the metal that height and width, then annealed and hammered it over the anvil horn, repeat, repeat, repeat, then closed with curved pliers. Not fun! I’m hoping for a formula that takes into account the width of the band, so I know what length I need to get next time. What I should have said is that the 1.67 cms is is diameter of the ring sizer hoop that fits the base of her finger perfectly. From the earlier experience I know I need more metal as it needs to sit on the fleshier part of her finger above the base. I guess I need to use a ring sizer on that part of the finger this time round.

I like to make rings with wide bands, particularly with large stones, and had this problem at first. The wider band makes it harder to get over a knuckle and also feels tighter on the wearer’s finger - even when you hit the size exactly. It’s not clear whether this is a sizing issue or a perception/feeling/comfort issue.

Regardless, here is what I have done to deal with this. First, you might want to consider getting the app iMakeJewelry. It contains a ring blank calculator and an adjustment for bands wider than 4mm - about 1/4 size. Second, some people just don’t like the feel of that much metal under their finger. For those people I taper about the bottom quarter of the shank. I usually start by taking away about 1/4 of the shank width. This usually does the trick.

Thanks Lindie’s, I do use iMake Jewelry, and chose the rink blank length indicated with >4mm and it was too short - is you suggestion of making it 1/4 bigger, 1/4 of the length of the blank? It seems very big …. Sorry to be so dense, it’s early in Aus, and I need coffee!

I’m not sure you need an app to figure it out. The circumference of a circle is the diameter multiplied by 3.1416 (π). Then you need to account for the thickness of your metal, doubling the 1.2cm. Are you really at 1.2cm or is it 1.2mm?

As stayed, when you a have a wide band you have go up in the ring size. If it’s a very wide band (1.5cm) you need to go up more. Most rings are only 1.5mm to 3mm wide. 6mm is a wide band for some, so 15mm is a very wide band. The wider bands take up more surface area that you need to account for.

To figure the correct finger size, for most it is how it goes over the knuckle, not the base of the finger. If the base of the finger is larger than the knuckle, then you would use that measurement. So in the US 1.67cm is about a size 6. The length would be approximately 5.25 cm you add on the thickness (let’s assume it’s 1.2mm) your at 5.5cm. You now have to add a little extra for the extra size you need, maybe two sizes, maybe a bit more. It can be shorten later. A quarter of a size was never enough in my experience. You also need to account for any squaring of the ends of the blank before you join them. It’s been my experience that it’s very hard to get the metal to curve at the correct radius at the ends, by using a longer blank joining it, rounding it on a mandril and then shorten it to the correct length, will be a smoother circumference.

Many blanks will come somewhat tempered, I think you can order blank metal sheet, in different hardness. (I made my own). From what you are saying, it sounds like you might not be getting the blank hot enough to anneal it fully.

A ring bender like the Pepe is a good investment, by the way. A lot of knowing how large to start, comes with experience.

Tjones

Goldsmith

Just for clarity for those of you using imperial measures.

1.2cm is 12mm which is approximately 1/2 inch.

So the ring will be a full inch thicker than the finger…

To me that sounds quite uncomfortable to wear.

Just for visualising the whole situation.

Apologies for the slow response. I did mean an increase of 1/4 US ring size, not a quarter of the blank length. I haven’t ever made a shank 12mm wide though. I would think that width would restrict movement unless the customer has huge hands.

Maybe I misread you, but the way I understood it was:

15mm wide and

12mm thick shank

at a diameter of 16.7 mm.

If this is wrong please correct me.

Best regards Per-Ove

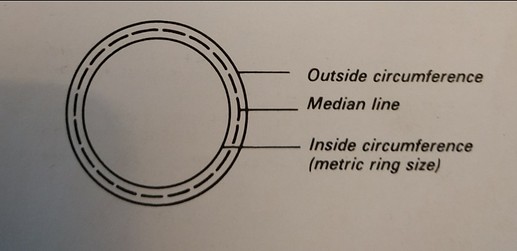

The length of the ring blank strip should not be equal to the inner circumference, but rather to the median circumference. Big difference. When the strip is bent into round, the outer circumference stretches and the inner circumference gets compressed. What theoretically stays the same is the median circumference, and that is why it is calculated and used to determine the length of the strip.

The inner circumference is the ring size.

The median circumference is [(inner circumference + metal thickness) x 3.1416].

Length of the strip blank should be equal to the median circumference.

For bands wider than 4 mmm, add 0.5 mm to the length. Since your band is SO much wider, you may have to add even more.

The ring size (=inner circumference) obviously must be able to go over the knuckle in one way or another ![]() .

.

Janet in Jerusalem