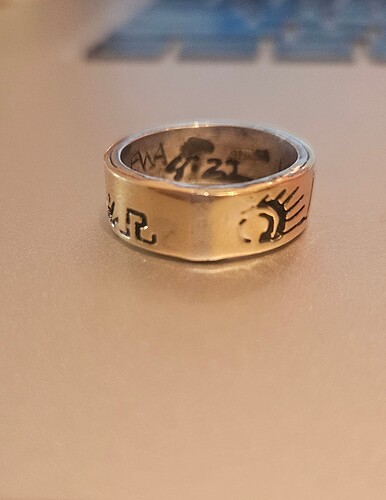

Thanks for the kind wishes; I hope your day’s going great too! I took a close look at the pics of your overlay ring (love the Navajo-inspired design work). I’ve handled quite a few of these gold-on-silver overlays over the years.

To answer your first question, yes, it’s doable, but definitely on the riskier side given the materials, cutouts, and the amount of sizing involved. Going up nine sizes means adding about 7 mm to the inside diameter, or over 20 mm to the circumference.

To be frank, it might actually be easier to recreate the ring and recycle the old one. The work involved in fabricating a new bimetal section would nearly equal the effort of making it from scratch, in my opinion. Splicing in a new overlay section is basically like half-shanking the ring but with a lot of legacy baggage. Still, I suspect the original piece carries sentimental weight, and that’s something we have to respect.

Dissimilar metals like 14K yellow gold overlay on sterling have different expansion and contraction rates, but usually the gold moves with the silver base without too much trouble. The cutouts, though, complicate things. I also notice in your photos that the fit between layers isn’t especially tight, which makes me wonder what solder was used during fabrication and if this will give you problems going larger.

Old 14KY can get brittle, especially if it’s seen exposure to hot tubs or pools. The gold layer can crack or delaminate under stress, and opening the ring that much could cause micro-cracks since the cutouts weaken the structure unevenly. From your pics, those fine motifs look particularly vulnerable, especially if the ring was stressed during the earlier resizing.

Be sure to explain these risks clearly to your client and let them make the final call on whether to proceed.

Your plan to remove that messy previous resize is spot-on. It’s hard to predict exactly how much distortion you’ll get in the cutouts, and delamination is always a risk. Work slowly in stages, annealing every few sizes, and keep the band round with gentle, non-marring hammer taps.

Also, make sure the gold you add matches the color of the original. Not all 14KY alloys are the same hue, so you might want to check with the client if color consistency matters to them.

If you have access to a laser welder, it could be a lifesaver for repairing small cracks or separations in the gold.

It sounds like you’ve got a good handle on what this job involves, so best of luck with it!

Let the community know how it turns out if indeed you take it on.

~AJ

![]()