So, Ive resent it as you request,

however theres STILL an issue!.

The original post arrived,

I go to topic,

im auto logged in,

I reply ,

it comes through,

Randy replies,

no problems.

then i write a reply exactly the same way to his second post,

but theres no reply button like to the 1st post ?

so I send it as an email.

Gets rejected.

Send again with a full title,

Lets see if it works now.

Ted

Hi Ted - please email us support@ganoksin.com if you are having any issues. We would be glad to help!

Morning Leah, I know its Sunday, and dont expect you to look at this till tomorrow , so I have just checked my long post to Richard Hart, and its not the first time its happened. The s/ware has ruined my typing by messing up the formatting. It makes it very difficult to read. Thats because the box I have to type it in is less than 1/4 of my normal page on screen, and when it expands it in the forum page its all over the place.

Can we please have a normal full page into which one types any post or reply? just like in an email or letter?

Have a look and tell me what you think.

The typing box is ok if one is writing a couple of sentences. otherwise its rather useless.

Ted.

You can put your cursor on the thick blue line at the top of the typing box and drag it up toward the top of the screen to increase the size of your typing box.

The small typing box is designed to allow you to see the post(s) to which you are responding which helps to keep your writing tight and on target. I find it helpful to frequently edit as I write and to use paragraphs to separate thoughts.

If you would spend some time reading our archived threads (it’s the first place a person with a question should search), you would quickly see why readers become bored with verbosity and do not read read long posts.

Pleasntries aside,

its sad that you find my posts boring and verbose.

Most have been historical, and if what ive done over the years just maybe helps someone to go with their desire to be a applied art metal smith then its all been worth while despite your comments.

when Rec crafts jewellery closed and became Ganoksin Seth asked me to reconsider leaving and stay, despite me saying I didnt really fit into this bench jewellers pidgeon hole.

As to looking for help? who else has a production setup like me?

No one. so I dont ask for help when theres none about.

Ted.

Now you have ‘almost’ made up your mind, sadly you need another driving

force behind you. Why don’t you teach your craft to the 'newer generation’

as I am now doing non-stop “24/6 @ 365”. The newer jewelers today need a

new source of information in creating their jewellery, you just might be

the person they desperately need. Come back tomorrow and think over your

decision, don’t do anything in haste!

*Gerry Lewy *

Toronto.

Ted’s posts are verbose, perhaps, but well-thought out and backed by knowledge and experience.

Though that style may not suit everyone’s taste (or needs) our readers have a choice and those who are looking for real insight into the subject at hand will find the helpful details that are often omitted in simple replies to queries.

Thank you, Ted for your contributions; I’ve found much of interest to me even when I’ve scanned one of your posts only out of curiosity.

Hello Pam,

thanks for your thoughtful comments.

As mentioned in my response to Betty 2,

IF,

I can , by putting the other point of view, ie wrought work, it redresses the imbalance thats there from the close focus on fabricating and casting.

Especially for beginners, who only have whats normally on offer to guide them.

Theres so much that wrought work can do, especially in the time saved, and thus financial viability of this craft. Wrought puts a lot more of YOU into your piece. It always shows.

Ted.

.

Hello Ted - I would like to offer my encouragement to you to hang in with Orchid. Having retired from a 40+ year career in fluid power and mechanical engineering, I really appreciate your showing and discussing additional ways to “skin a cat” while still achieving a great result. Your post on belt buckle manufacturing using stamped tabs is an extremely good example.

Orchidians, with all due respect to all of the jewelry arts training organizations, the vast majority of the training and info provided is excellent. Ted is showing us an optional way to perform tasks beyond what might be considered the norm and stands a good chance of being the difference between overall success and failure. And for what little my background supports my opinion, I have found that nearly all discussions of engineering and production material lack the zip and pizazz found when reading a New York Times Best Seller. And it does take a lot of words to properly give sufficient info to another so they are able to replicate the originator’s result

So please hang in there Ted, there will always be some who dislikes something about someone but, there are some of us who look forward to your posts.

I am not quite sure how this conversation got stared but what I see is maybe Vladimir is leaving orchid? Please don’t! For all metalsmith like myself, completely self taught online, I depend and bow down to guys like you, well trained and always willing to share with us nobody’s! Old school metalsmithing is so valuable and your generosity is priceless, I just read an email from an artist who is crushed right now do a negative comment, I felt so sorry for her, I believe what my mom preached, if you don’t have anything nice to say don’t say anything! And again, I am so thankful to u, Gerry, Jim and all the old school jewelers, stay strong! Aloha, angi in hana

Hi Bob,

Thank you for your support.

The upstanding tabs punched into the buckle back is not new. I recall destroying! as a boy the tin toys where the 2 parts were held together , one with tabs and one with slots for the tabs to go through. also the metal strips for surface fixing electrical wiring. there the same. In my buckle, tho instead of 15/1000th its 1/10th in,thick.

then its worked some more, 2 of the 3 tabs are to support the 1/10th in thick wire loop thats to go on the leather side, and the other one, thats worked with several shaped punches into a hook to go into the leather to close the belt on the other side.

Surprisingly strong. Will take a 200lb weight.

Another piece is the folded over shape that also has 2 smaller tabs these hold the wire loop to the leather. single thickness.

The wire loop is made from s/steel wire some 1/10th in thick.c clamped between 2 by 1.5in by 1/2in steel plates. in a leg vice.( all wrought iron!) then the wire is just hammered round the steel to form the loop.

.This design was thought up to be able to make it all cold on site…

The blanking of the components is done at base.Buckle back with a 6ton crank press single shot.

The piercing of the tabs is done on site! with a small 2 ton, arched flypress and tooling.Made that myself as its not normally available.

tho any tool maker could do it.

Finally! what i have here really isnt new. Its the way the B/ham UK jewellery industry developed in the 1880’s.

I do have modern kit TIG etc by my main drop hammers are 1889 and 1870.

Ted.

What’s this “ old school” we are just “very mature”!

I’m Gerry, On my iPhone!

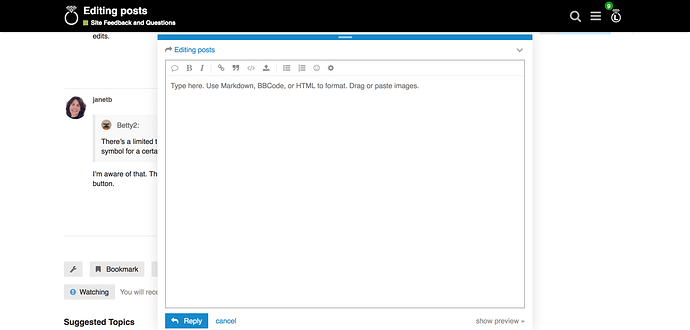

Hi @vladimirfrater. I checked and it looks like there’s no full screen editing mode but I found something else that’s sort of handy and perhaps helpful.

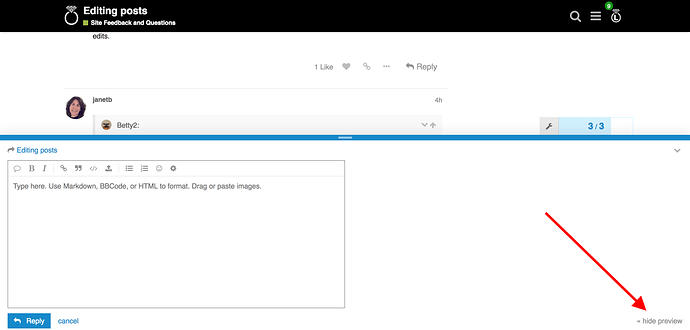

I noticed that you can click the “hide preview” link:

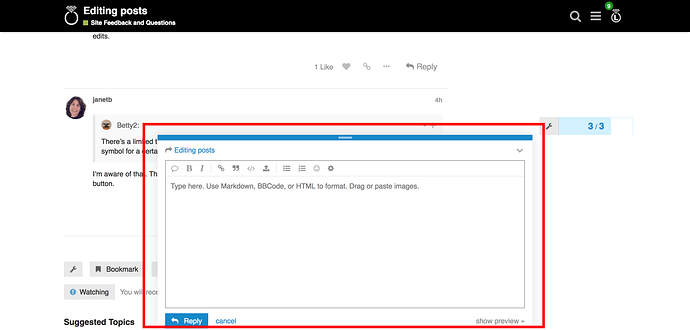

And just get yourself one editing window like this:

And then drag the top of the box to be longer:

That might work better for longer posts. Hope that’s helpful!

I use the “preview & the two window” format constantly!

I get to see just how the final posting will look. My feeling is, if I don’t like how it looks, then the reader won’t. I call this ‘trial & little error’, you just gotta EXPLORE and not to be afraid of losing your text.

For this, I now write on my “Word2013” and “highlight the whole essay” then I drag it to the “main page”. As for my multitude of pictures, they are all stored elsewhere in folders.

Does this take time? YES, but look at the results!

I’m Gerry, On my iPhone!