This question is for the lapidaries among us. All the stones that I cut are freeforms. I have a Kingsley North six wheel lathe with all diamond and diamond/resin wheels. I can usually get a good polish, but it is sometimes a struggle. I am considering buying a small rotary lathe to do the finish work on, 600 grit and then polish with whatever works best for the type of stone. While I have a large AV25 and 2 TV10s, they are too noisy for a long run. I am looking at the Lortone 3a as it is reviewed as the quietest of the small rotaries. Any thoughts are appreciated. Happy Holidays to all if we don’t communicate again before Christmas…Rob

I could also just buy another barrel for my QT6, but I am not sure if it would be too big for the runs that I anticipate.

Hi Rob

When I was regularly using my vibratory tumbler, I set it up on a covered patio (in warmish Arizona). If you have a garage or shed separate from your shop that location might be an option if it doesn’t freeze.

HTH,

Pam

Pam…Thanks, I have done that in the past when polishing metal. Unfortunately, I live in Central NY where it is currently a high of 26…Rob

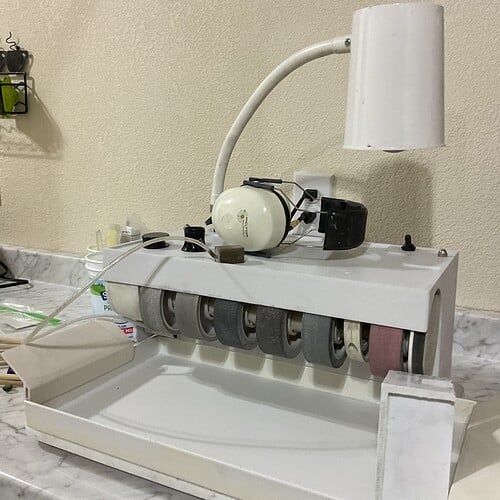

This is my lapidary system and it has been great. The vibratory unit lives in the garage on a foam pad and leveled with a wedge. The dry compound is wonderful and the unit is for polishing brass for bullets.

My lapidary equipment is very similar to yours. I also have an 8” magnetic flat lap and a 14”, 8” and 6” saw. The 6” is a trim saw. Vibra-dry is an interesting product and I have looked at it previously, but thanks for sharing it. What I don’t know is if you use it both dry and without any filler like non-abrasive ceramic beads to finish lapidary. Used by itself, it could get expensive, especially if there are multiple steps. The fact that you use it dry is a plus. I just want to finish preforms that have been ground to shape and sanded to about 600 grit. I would like to explore, ideally, using a rotary tumbler to keep down the noise to do the finish sand and polish on these preforms but Vibra-Dry is best suited for a vibratory tumbler. How I get there is yet to be determined and I guess that it is my question. I have used vibratory tumblers to finish silver jewelry for years, but not with Vibra-Dry. Thanks…Rob

I have done a lot of research since my last post. I am zeroingin on a Diamond Pacific mini sonic or a Lot-o-Tumbler each with an extra bowl. I like the idea of vibra-dry because it can be reused and also will polish metal, so they say. Any thoughts are appreciated…Rob

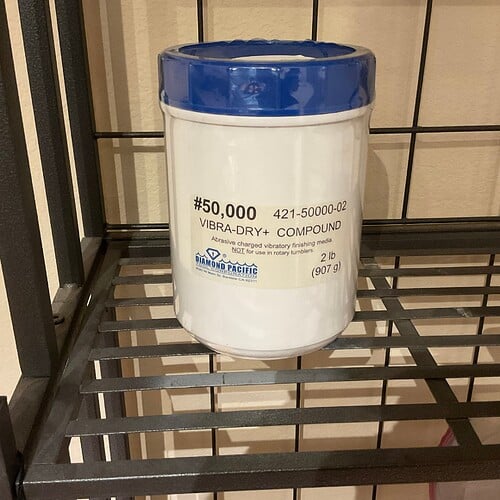

I quit experimenting with Vibra-Dry+ 50,000, I just use it for all dry finishing. The shine is outstanding and very gentle. I used it in the mini sonic and it was ok. I bought a lot of it and run it in my 6 qt cartridge cleaner vibratory tumbler - it is very quiet. They (diamond pacific) don’t always have the range of grit but the difference between 25k and 50 is not discernable to almost any client.

I don’t have a normal shop since I experiment with mechanical finishing. Currently I have a 8 inch ikohe pin finisher, 3 - 8 qt flow thru vibratories, a little tiny lortone vibe, the afore mentioned vibrasonic, a wierd vib that looks for all the world like a salad tosser, a giant 40# rotary and a normal 4# rotary and at least 1 dozen different abrasive media and 4 or 5 different non-steel polishing media. And a couple of ineligant Harbor freight vibratory tumblers. I have buckets, pumps and a cart to move the full 5 gallon buckets. Too much for regular folks, but i have learned a lot about mechanical finishing.

Judy…Thanks for sharing what you do and know…Rob

I have been following this thread as I am looking for new tumbler myself. I have used a very generic, basic rotary tumbler from a hobby shop for the last few years. Mainly for tumbling rings, earrings, earring wires and dressing up a bit of small shop worn display pieces. Except for the small size I’d go back to the same unit. It did what I needed. I certainly got my $50.00 worth out of it. I will be tumbling sterling, copper and brass. Mostly.

The price isn’t a huge concern. The tumblers I have been drawn to, Lortone QT-6, all seem to be out of stock or they, Diamond Pacific, have a very long lead time before shipping. I would buy a second barrel for just dry media for which ever I choose. . I am following Rob’s lead looking at the Lot O Tumbler. Pepe has a Magnetic Tumbler with a 4” barrel which they say will handle 8 rings. This seems like a very small load but I am used to much bigger capacity rotary tumblers so I am out of my depth with magnetic devices.

I am not a lapidary but I wouldn’t mind having a tumbler that gave me a finished bit of rough. Quiet would be nice but it isn’t a major concern. And depending on the size of the machine it will live either in my shop or on the screen porch.

Any ideas?

Don Meixner

Look at Kingsley North. I believe that they have the QT6. I guess I need to know what you want to tumble. You should stop by and I will give you a tour of my tumblers and we can discuss which does what. I am set up to polish metal either from scratch or just a touch up. My current interest is in polishing lapidary preforms so that I don’t spend so much time polishing one at a time…Rob

Hi Rob,

I will stop by. After the holidays and trips to Maryland and Indiana.

As per our chat I pretty much tumble things to soften an edge or two, brighten up some surfaces dulled by fingers at shows, and remove flux and soot from freshly made bracelet straights. Most of this I do in a large vibratory machine with stainless shot and flow through capability. Doing my research I am discovering the jury is out on magnetic pin machines. Mostly because of minimal capacity and small runs of finished products. And the finish isn’t what I am used to and my customers like to see.

I am exploring the reloading industries as well. They are tumbling cartridge brass and using compounds that must be similar to what we use. I looked at Diamond Pacific and I liked what I saw. But remember: I am not a lapidary so I would need to have a good idea of what using the Diamond Pacific machines with just metal forms in the mix is like.

And I have an old Viking twin hopper vibe that Dad gave me. I haven’t explored that machine at all……..Don

Large magnetic tumblers can be made if one is interested.

This by former Orchid member John Donivan:

Trigger warning, in the youtube below the guy broke something. There is an ‘expletive’.

Neil that’s the kind of stuff I lived for back in The Boatyard Days. Thank you! I’d undertake that job in a heart beat and a six pack of Matt’s. I suspect it could be built with a plywood base and a smaller lower hp motor. Something to try when I am visiting my son in law and his shop. I suspect the magnets would be the hard thing to find anywhere but on line……Don

Rob - while I have a mini-sonic, I don’t like it. It works fine but - getting the bowl out and in is really hard. It is a friction fit and it has a lot of friction. You need to have really strong hands and arms to do it. Maybe you are lots younger and stronger. The bowl likes to be empty to remove and insert, else you get media all over the studio. And if you are running steel in it, it is nearly impossible to get the blankety blank bowl out with water and steel. On the plus side, it’s pretty quiet. For my money, I’d get one of the very small little green vibratorys - about $100, raytech tumble-vibe. It’s basic. One concern about either however, you work needs to move freely inside and I think you make a lot of bracelets.. in which case I’d recommend something larger. the reloading sites have lots of choices for dry media tumbling and my experience is that they work just fine. Even the harbor freight ones - their 5# dry vibe is $69, and that’s without their regular discounts. Judy

Ok, some basic info - a rotary tumbler burnishes with steel. For metal, that’s all it is good for.

The vibratory ones smooth with some kind of abrasive media, run wet. To get a really nice shine you use Diamond Pacific Vibra-dry+. Here’s the bit - that media is expensive, so figure how much media you need to fill a bowl at least 80% for what ever tumbler you use. I opted for mostly 6 qt vibratorys. The media doesnt wear out. I don’t like to change media in bowls, thus I have several 6 qt units - one dry and a couple of wet. Because it doesn’t matter, I use a cheapo dry one from a gun shop, it’s run for more than 15 years. Here’s the other matter - if you are running 1,000+ pieces weekly, buy the best quality you can afford. If you hand make your stuff, it isn’t necessary to spend gobs of money because you won’t run the machines that hard.

Hello Judy,

Thanks for the info. I have been toying with the idea of smaller, dedicated units. One dry, two flow through. I make a number of pendants that have pretty inaccessible areas that a wheel can’t reach. Perhaps a small magnetic is the answer there. I am a supporter of the big Harbor Freight flow thru vibe. I have run one pretty constantly for five or more years. The down side is they are noisy because of the thin walls on the tub. But I am pretty deaf so it probably bothers my wife more than me.

Don.. the other Meixner.

Judy…I am pretty well set for tumbling metal. I have three flow through tumblers with different ceramic media. My question has do specifically with tumbling small lots of preformed lapidary. I will do all the initial grinding and sanding with hopes of doing the pre-polish and polish in a vibratory tumbler. I have cut and polished stones for years, one at a time. I am processing a large amount of lapidary rough that I inherited from our father over 30 years ago and would like to speed up the polishing process. I am especially interested in vibra-dry for both metal and lapidary. Thanks…Rob

I don’t know about vibra dry for stones - I do recall that someone said that it is ok for cleaning jewelry including something with opals. Years ago Michael Hendrix (Minerex) did some really fine finishing on some nice stones with his magix elixer in the machine - and I’d guess that the 50,000 vibra-dry might do that. I do finish fussy stuff like jade with 50,000 but by hand on a wood wheel.. j

The magnetic one will help with recesses, but… you will still need to do a final burnishing run for high surfaces. The magnetic pins leave a sparkly finish.. j