“**_Pumice Wheels @ #180 grit!_**”

There are many tools on the market these days that are used constantly in the “Diamond & Gemstone Setting” processes. The one that I believe is most important, is not the Pillar or Triangular file, but the often ignored and the very reasonably priced, Pumice Wheel”.

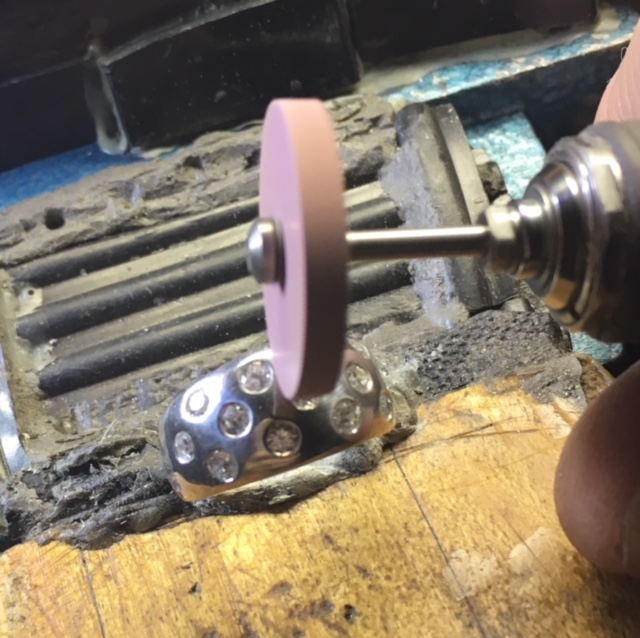

Many setters that I know, including myself, use only the #180 Grit. There are many smoother grits a.k.a. #240 available, I prefer the basic #180, why so? It’s not so aggressive by nature, but still it cleans and is really very gentle around anything that you are setting & even cleaning. Let’s suppose that after you complete your filing around Claws, Bezels and even the Channel-Setting, try these fantastic Pumice Wheels.

If you are not using them, you have just nothing to lose, the results that you are going to find are just mind-boggling! You should now experiment where you could find other uses for them. In your jewellery fabrication, these can be a ‘real life-saver & gift’ for your cleaning, even prior to the polishing with your wheel-buffs.

“Pumice Wheels have a symbiotic relationship with that in setting of gemstones”. To put it another way, they both live in harmony and each depend on the other…“it’s like a happy marriage!”

After your filing, there are even little striations left on the metal, so how do you remove them? Don’t polish them off, why not? Easy answer, you’d be then making all the ‘squared-off’ claws or flat surfaces, actually will be then rounded, not too nice to see after your hard labour. (I type and use the “Canadian-spelling” version, in all of my essays.)

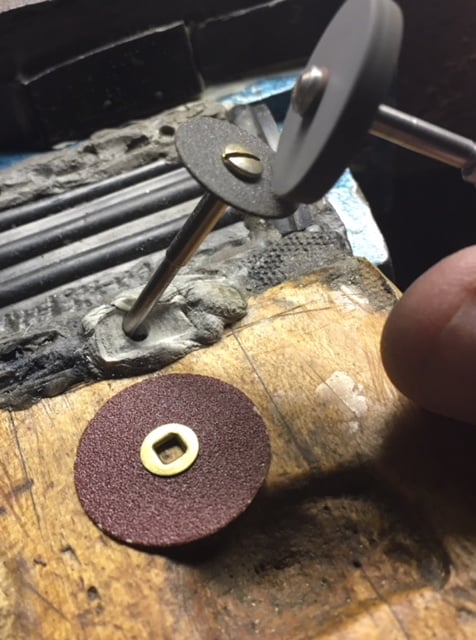

To continue on; let’s suppose you’ve used your ‘Emery Disks” just to do some last minute cleaning and you still notice some rough surfaces. You say to yourself, “What happened, they weren’t there before?” The ‘Fine’ or ‘Medium’ grit on the sanding disks are to blame, STOP! Get out your Pumice wheel and ‘redo’ those rough-textured surfaces, the end result is that they will now be so very smooth!

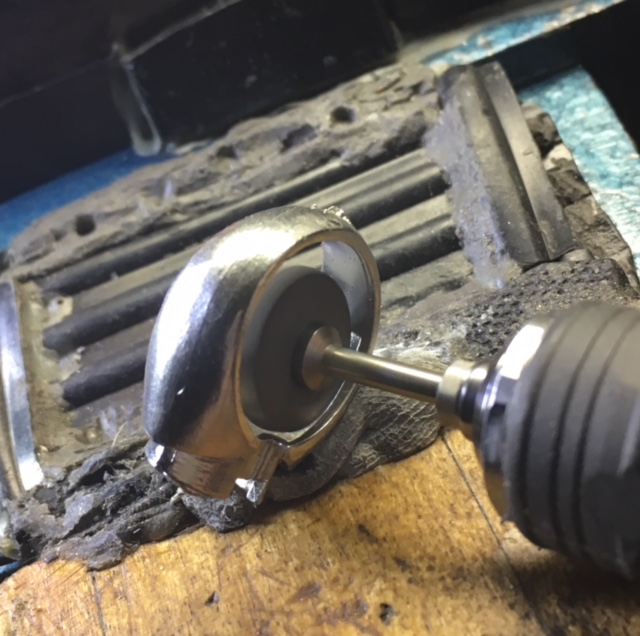

In the ‘demo’ photographs, many of the rings are ‘staged’ just for this essay. Of course, I wouldn’t be holding or supporting the rings on that soft material shown on my bench that way. They are only to demonstrate how the wheel will be in ‘contact to the claws and surfaces’.

What stones can I use these wheels next to? With great care and experience, these can be used literally beside any soft stone! Although it does need some practice to use them near Blue Zircon, Amethyst, Turquoise, Opal and very, very carefully…Pearls! Anything over 8.0 on the ‘Mohs Scale of Hardness’ is acceptable.

For example on the Gypsy/Flush setting, just use a Flat-Faced wheel and ever so lightly making contact with the outer rim of the delicate stone. Don’t let the Pumice wheel get too close to the Cubic Zirconia or as it will graze and destroy the facets; a.k.a. 'Woops! Good-bye stone"

I have 12-15 of the ‘wheel mandrels’ in my container of assortment of new and used wheels. Why so many? The time you are spending using the wheels, you might be just wasting precious time removing one wheel off of the mandrel, from one shape to another. Just buy many of the mandrels as you can and keep your mind on your work, not stopping to remove, put another wheel on, taking it off…ad infinitum!

I, even at times, use the ‘worn out’ wheels to clean the inside of the ring. There are so many other uses, all you have to do now is to be creative!! I always use these to finish off setting of the Princess claw “vee-shapes”. . On Bezel settings I use them as a rule on the top of the Bezel wall. “The Pumice wheel is a precursor to Tripoli and Rouge polishing on any style of gemstone setting.” After casting, there will sometimes be a need to remove little amounts of extra metal that a file cannot clean, and then prepare for setting. This fantastic wheel removes & cleans in one simple action!

After a short period of time, you need to keep your flat surfaces FLAT, how would you manage this? You could use your ‘sanding disk’ or a Corundum (Separating Disk) and just reshape your Pumice Wheel, as needed! It’s really not rocket science! You can just reshape them on any rough surface you have, even 'Emery Paper". Just keep those wheels ‘trimmed and cleaned’ then they’re ready to be used again.

In my opening remarks, I did say that these wheels are a ‘gift’ to your jewellery bench. Learn to use them as often as you can, explore those little areas that you need to be cleaned.

BTW, I even use the #1,000 grit “Pink Wheel” as these could be used in lieu of the polishing cloth-wheels. Why use the (almost-aggressive) “Tripoli or Rouge cloth-wheels”? You have been using them with little success, you could now use the #1,000 grit instead! Now you can ‘set’ those delicate myriad of stones while in their claws and have them cleaned so easily.

I sincerely hope that you have 'found a new friend for your bench work’, they are the Pumice Wheels! Two words for you to remember, they are; “Enjoy & Enjoy!”