Those are lovely. May I ask what tools you used to cup the petals of the flower in the fourth photo? I think that information is what I’m looking for in the question I posed about forming anodized aluminum. Thank you.

Hi, I used my RT/Pancake dies to cut all of these parts. At the time, I was doing “V1.0 combo dies” (the pancake cutting die is etched and used to cut the flat part and then emboss it in two separate pressings), like the first picture here

This version had a potential flaw for some designs, so I abandoned it in favor of “V3.0” , which is a plain, non-etched pancake die and a separate , etched impression plate : video demo : Combo Dies V3.0 – Impression plate and Pancake die (youtube.com)

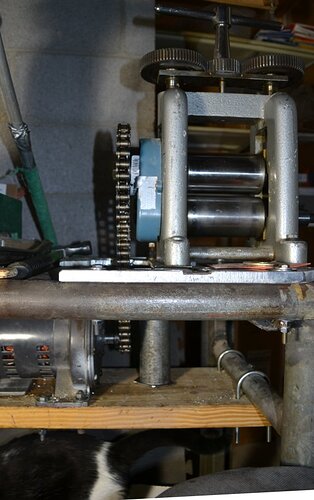

Most recently, I’ve found that a rolling mill is easier/better for embossing the designs than pressing with the “normal” 20 tons, and even my 50-tonner wouldn’t press the ornament parts (24 ga. copper ) I made etched plates for, in one pressing. So, I fiddled with my mill (extended handles, then a gear motor) and it rolls them nicely , but does hit a wall because the motor is only 1/2 hp (the electric ones from Durston I saw at Rio Grande are 1.5 hp).

So, the progression of these “progressive” pancake dies has gone through several phases in a year, but the basic action of the cutting dies has always been the same, with the exception of the short-lived V 1.0 , which were etched , but still function the same as far as cutting, and can even be used to cut flat parts, like normal RT/pancake dies.

Unfinished rolling mill project:

Regular RT/pancake die:

Here is the old finished V 1.0 large Mermaid die that is show as an etched plate in the original post. Enameled sample was made by Nancy Yonehiro (Angst and Attitude) for my wife. The copper ornament-sized parts are very recent, made by putting the etched impression plate through a rolling mill with craft foam, then cutting in a regular (made by me , to cut thin metal cleanly) 3" circle RT/pancake die.

Front and back sides of the Dragon are shown. The Dragonfly was at the limit of my rolling mill’s motor’s power, so…bigger sprocket on the motor , or bigger motor… sprockets are cheaper, and I only need a little more power (^8