What gauge and what brand of piano wire have people used for hanging pendants or other applications that require longer, more supple wire? Can it be blackened?

Piano cannot be considered “supple”. It is hardened stainless wire so not much chance to blacken it.

Do you know what wire it is that some folks are using in place of

leather or rubber cord? Often I see necklaces with multiple strands of

thin wire, and I don’t think it is silver or other precious metal.

Thanks.

You can start here and see if there is something that you like: Search results - RioGrande

I make twisted wires that I use to hang pendants. I usually use brass, copper and stainless steel of 28 or 30 gauge wire, but silver, silver-filled, gold or gold-filled wire can also be used… The number of strands I use varies from 10-100 or so. I measure the wire by stretching it between a nail I clamp in a vise and nail in my work table that are about 10 ft.apart, so I can make enough for several pendants at one time. I cut the end wrapped around the nail, tape the ends together with masking tape and put the end into my flex shaft (a REVERSIBLE electric drill will work also). Twist until the desired effect is achieved, making sure to keep tension on the wires at ALL times. If thicker wire and/or multiple colors is wanted, repeat these steps until you have the long, twisted strands that you want. Anchor all the strands in the vise, be sure that the tension is as equal as possible for all of the twisted strands. REVERSE THE DIRECTION OF ROTATION ON YOUR FLEX SHAFT. This is critical - if you twist a second consecutive time in the same direction, your wire will kink up. Twist all of the strands until the desired effect is achieved. Store the wire in a coil; if it is creased, the crease will never be completely smoothed out. This wire can then be cut to the desired length with sharp scissors or wire cutters.

To finish the ends of a necklace for a pendant, I either cut tubing into 1/2-3/4" lengths (the interior diameter of the tubing should be similar to the wire diameter) or use barrel beads. Then make a hook and eye or eye pins with long ends. Wrap the long end around the necklace wire until it is securely attached. Slide the tubing or barrel bead over the wrap and secure. I don’t solder ends on the wire because the 28-30 gauge wire melts and burns very easily, even after it is twisted. Even if the soldering is successful, I have never been able to get this wire back to a polished state. I then seal the wire with Protect-a-Clear, because polishing is not very successful, either.

Good luck!

Thank you so much! I really appreciate the detail.

Rosemary

Hello again,

If you don’t mind, I have a few follow up questions.

- can the “desired effect” be a soft, loose twist or does it need to

be a cable? - do you reverse the direction of rotation each time you add

another strand? - how do you secure the tubing or barrel over the wrap?

- where do you get fine gauge stainless steel?

Thank you!

Rosemary

Rosemary - To answer your questions:

- I make cables, but especially the last twisting can be loose. Just keep

in mind that a loose twist will come untwisted more easily, making putting

the end caps on a bit more difficult.

2.I make all of the bundles of 10 wires that I want to use, all twisted in

the same direction. Let’s call this twist #1. Bundle a bunch of these and

reverse the twist direction for twist #2. The #2’s can then be bundled and

then reverse the direction of twist again (so they will be twisted in the

same direction as twist #1). Call these twist #3. Continue to bundle,

reversing the twist each time, so that all odd-numbered twists go in the

same direction as twist #1 and all even-numbered twists to in the direction

of twist #2.

This way, you can make wires with thick strands of single colors, or thick

strands of mixed colors, depending in which bundle(s) a single-colored

smaller bundle or multi-colored smaller bundles are used. You really have

to play with this process to see what produces the effect you want.

The point in reversing the direction of twist is that you don’t want to

re-twist a bundle in the same direction as the individual strands in a

bundle, as this will cause kinking. The kinking can be pretty, but the

edges are sharp and not usable for jewelry. If you know anything about how

yard is plied, the same rules apply. In general, you want every strand in

a bundle to be either an odd-numbered twist or an even-numbered twist;

avoid combining odd- and even-numbered twists in the same bundle.

-

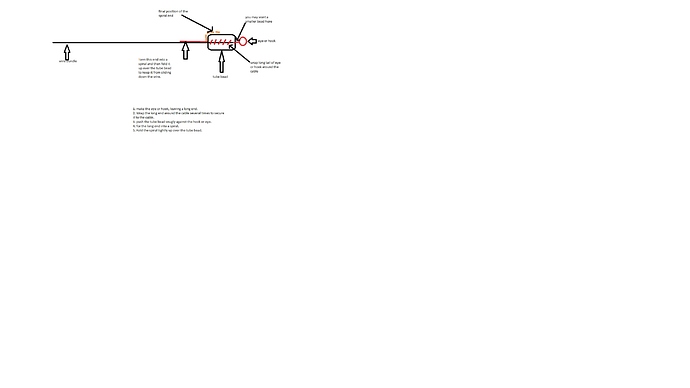

I’ll attach a drawing that shows this.

-

Search for 28- or 3-gauge stainless steel wire on Beadalon, Amazon

or

many other beading sites.

Of course, you can also use wire other than round wire in the bundles to

create different effects. The possibilities are endless! Let me know if

you have any further questions.

Thank you again!! I will try this soon.

Rosemary

Hi Rosemary,

There are a couple of types of wires that I have used, they are used in the fishing industry! there is a nylon covered multi strand that is fused when twisting a finish on it and the other is a black multi strand stainless that is softened with heat to do the twist finish. these are great for beaded necklaces or heavier gauges for necklaces that have no beads.

here are a few types:

http://www.ebay.com.au/itm/50m-0-80mm-49-STRAND-STAINLESS-STEEL-FISHING-WIRE-MULTI-STRAND-65kg-WIRE-TRACE-/331842912536?hash=item4d43610118:g:HgoAAOSw3mpXIhIp

All the best with it ![]() Philip

Philip

Thank you!